Part 3 INITIAL STEPS FOR INSTALLING YOUR DRYER

STEP 4 Connection of Gas Supply

STEP 4 Connection of Gas Supply

(Gas dryer only). In addition to the following, please refer to manual section on Gas Requirements and Instructions.

![]() 1

1 ![]()

![]()

![]()

![]() 2

2

![]() 5

5 ![]() 3

3

![]() 4

4

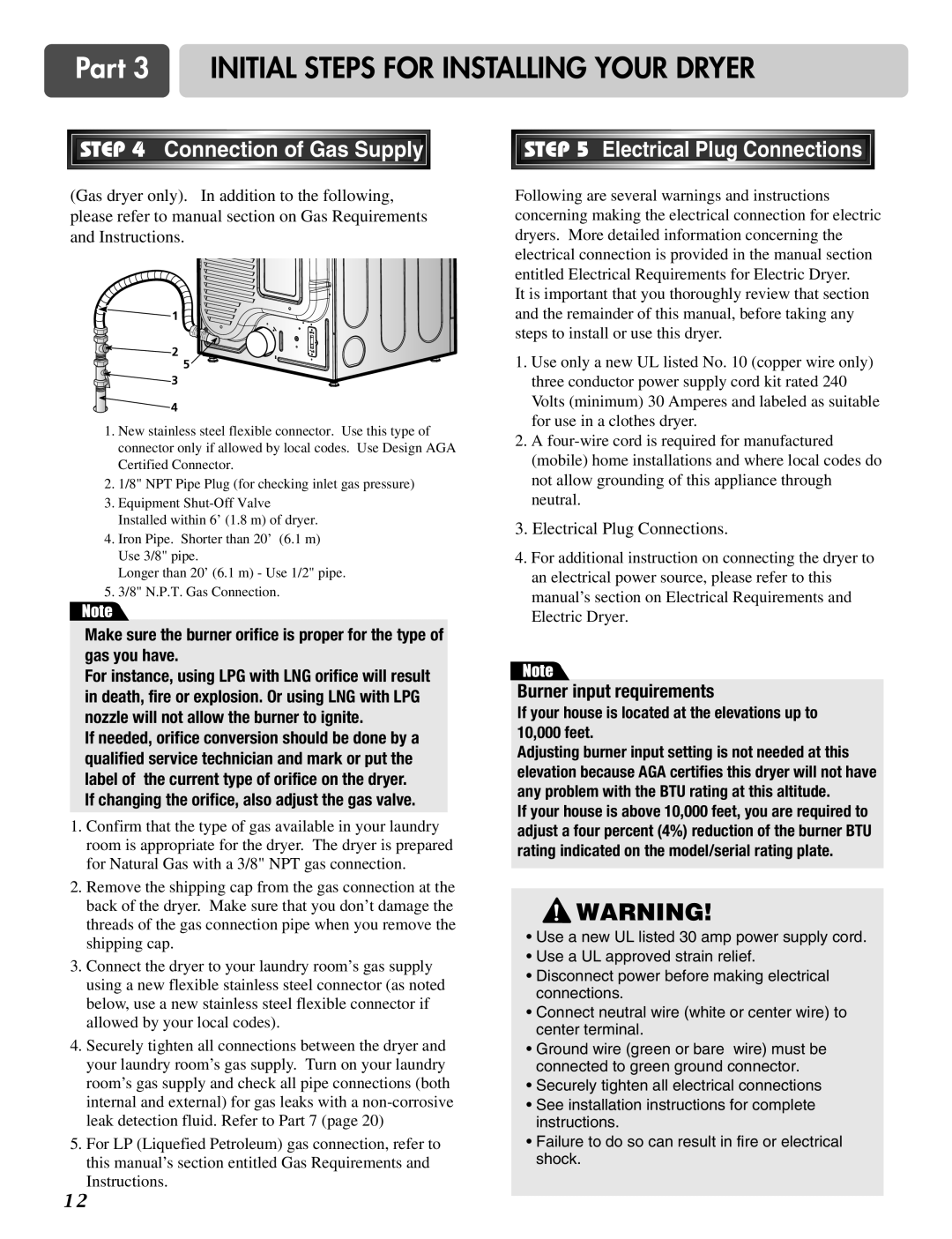

1.New stainless steel flexible connector. Use this type of connector only if allowed by local codes. Use Design AGA Certified Connector.

2.1/8" NPT Pipe Plug (for checking inlet gas pressure)

3.Equipment

4.Iron Pipe. Shorter than 20’ (6.1 m) Use 3/8" pipe.

Longer than 20’ (6.1 m) - Use 1/2" pipe.

5.3/8" N.P.T. Gas Connection.

Note

Make sure the burner orifice is proper for the type of gas you have.

For instance, using LPG with LNG orifice will result in death, fire or explosion. Or using LNG with LPG nozzle will not allow the burner to ignite.

If needed, orifice conversion should be done by a qualified service technician and mark or put the label of the current type of orifice on the dryer.

If changing the orifice, also adjust the gas valve.

1.Confirm that the type of gas available in your laundry room is appropriate for the dryer. The dryer is prepared for Natural Gas with a 3/8" NPT gas connection.

2.Remove the shipping cap from the gas connection at the back of the dryer. Make sure that you don’t damage the threads of the gas connection pipe when you remove the shipping cap.

3.Connect the dryer to your laundry room’s gas supply using a new flexible stainless steel connector (as noted below, use a new stainless steel flexible connector if allowed by your local codes).

4.Securely tighten all connections between the dryer and your laundry room’s gas supply. Turn on your laundry room’s gas supply and check all pipe connections (both internal and external) for gas leaks with a

5.For LP (Liquefied Petroleum) gas connection, refer to this manual’s section entitled Gas Requirements and Instructions.

STEP 5 Electrical Plug Connections

STEP 5 Electrical Plug Connections

Following are several warnings and instructions concerning making the electrical connection for electric dryers. More detailed information concerning the electrical connection is provided in the manual section entitled Electrical Requirements for Electric Dryer.

It is important that you thoroughly review that section and the remainder of this manual, before taking any steps to install or use this dryer.

1.Use only a new UL listed No. 10 (copper wire only) three conductor power supply cord kit rated 240 Volts (minimum) 30 Amperes and labeled as suitable for use in a clothes dryer.

2.A

3.Electrical Plug Connections.

4.For additional instruction on connecting the dryer to an electrical power source, please refer to this manual’s section on Electrical Requirements and Electric Dryer.

Note

Burner input requirements

If your house is located at the elevations up to 10,000 feet.

Adjusting burner input setting is not needed at this elevation because AGA certifies this dryer will not have any problem with the BTU rating at this altitude.

If your house is above 10,000 feet, you are required to adjust a four percent (4%) reduction of the burner BTU rating indicated on the model/serial rating plate.

!WARNING!

•Use a new UL listed 30 amp power supply cord.

•Use a UL approved strain relief.

•Disconnect power before making electrical connections.

•Connect neutral wire (white or center wire) to center terminal.

•Ground wire (green or bare wire) must be connected to green ground connector.

•Securely tighten all electrical connections

•See installation instructions for complete instructions.

•Failure to do so can result in fire or electrical shock.

1 2