9.0WIRING INSPECTION

ìï 9HULI\ýDOOýSRZHUýFRQQHFWLRQVýDUHýWLJKWï

ëï 9HULI\ýDOOýFRQWUROýZLUHýWHUPLQDWLRQVýDUHýWLJKWï

êï 9HULI\ýDOOýSRZHUýZLUHVýDQGýFRQQHFWLRQVýKDYHýSURSHUýVSDFLQJýEHWZHHQýH[SRVHGýVXUIDFHVñýSKDVHð WRðSKDVHýDQGýSKDVHðWRðJURXQGï

éï 9HULI\ýWKDWýDOOýFRQWUROýZLUHVýDUHýUXQýLQýLQGLYLGXDOñýVHSDUDWHñýVWHHOýFRQGXLWï

ý |

|

|

|

|

|

|

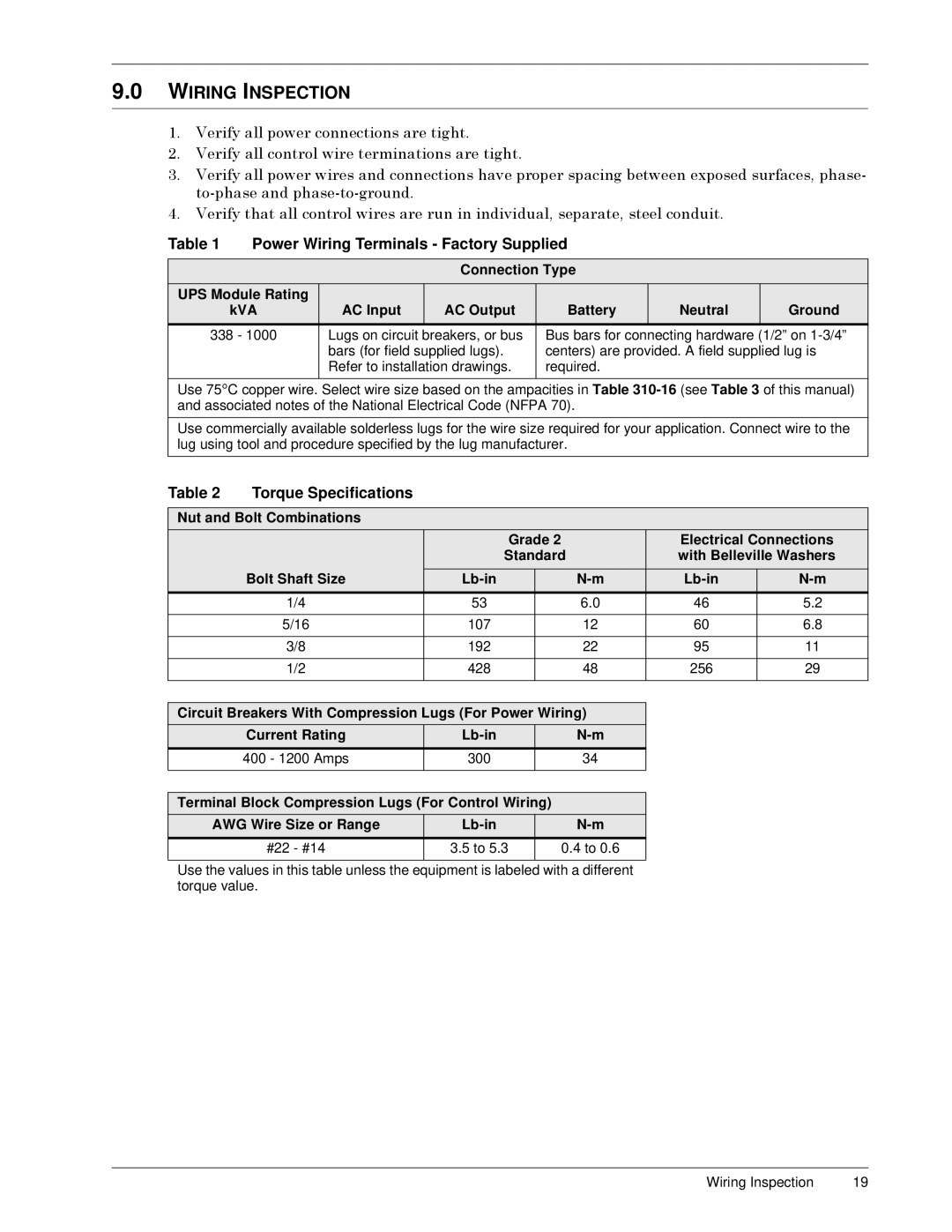

Table 1 | Power Wiring Terminals - Factory Supplied |

|

| |||

|

|

|

|

|

|

|

|

|

| Connection Type |

|

| |

|

|

|

|

|

| |

UPS Module Rating |

|

|

|

|

| |

| kVA | AC Input | AC Output | Battery | Neutral | Ground |

338 - 1000 | Lugs on circuit breakers, or bus | Bus bars for connecting hardware (1/2” on | ||||

|

| bars (for field supplied lugs). | centers) are provided. A field supplied lug is | |||

|

| Refer to installation drawings. | required. |

|

| |

|

|

| ||||

Use 75ƒC copper wire. Select wire size based on the ampacities in Table | ||||||

and associated notes of the National Electrical Code (NFPA 70). |

|

| ||||

| ||||||

Use commercially available solderless lugs for the wire size required for your application. Connect wire to the | ||||||

lug using tool and procedure specified by the lug manufacturer. |

|

| ||||

|

|

|

|

|

|

|

Table 2 | Torque Specifications |

|

|

|

|

|

|

|

|

|

|

|

|

| |

Nut and Bolt Combinations |

|

|

|

|

|

| |

|

| Grade 2 |

|

| Electrical Connections | ||

|

| Standard |

| with Belleville Washers | |||

|

|

|

|

|

|

|

|

| Bolt Shaft Size |

|

| ||||

| 1/4 | 53 |

|

| 6.0 | 46 | 5.2 |

|

|

|

|

|

|

|

|

| 5/16 | 107 |

|

| 12 | 60 | 6.8 |

|

|

|

|

|

|

|

|

| 3/8 | 192 |

|

| 22 | 95 | 11 |

|

|

|

|

|

|

|

|

| 1/2 | 428 |

|

| 48 | 256 | 29 |

|

|

|

|

| |||

|

|

|

|

|

|

|

|

Circuit Breakers With Compression Lugs (For Power Wiring) |

|

| |||||

| Current Rating |

|

|

|

| ||

| 400 - 1200 Amps | 300 |

|

| 34 |

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

Terminal Block Compression Lugs (For Control Wiring) |

|

|

|

| |||

AWG Wire Size or Range |

|

|

|

| |||

| #22 - #14 | 3.5 to 5.3 |

| 0.4 to 0.6 |

|

| |

|

|

|

|

|

|

|

|

Use the values in this table unless the equipment is labeled with a different torque value.

Wiring Inspection | 19 |