Instructions for installation and modification

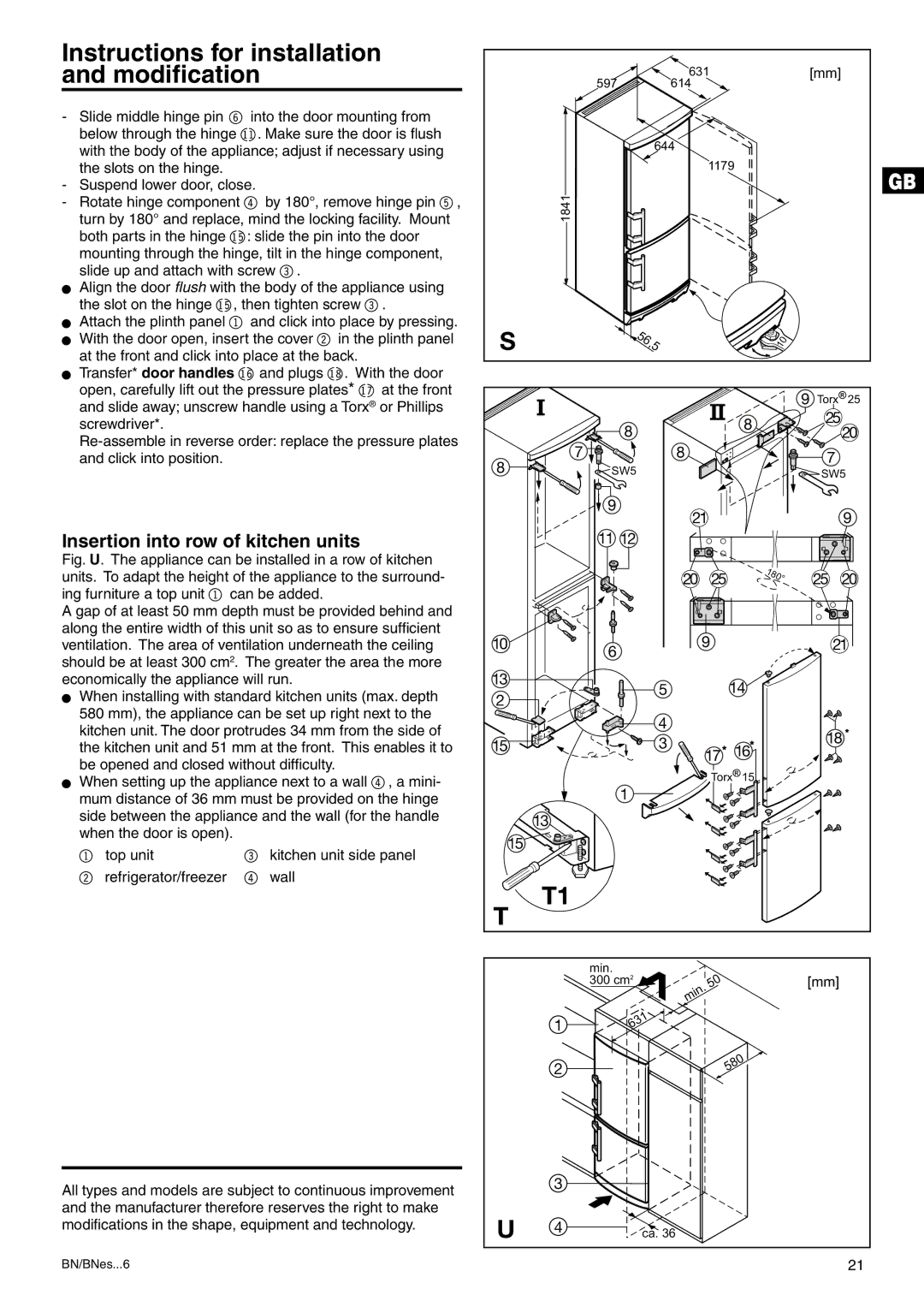

-Slide middle hinge pin 6 into the door mounting from below through the hinge bm. Make sure the door is flush with the body of the appliance; adjust if necessary using the slots on the hinge.

-Suspend lower door, close.

-Rotate hinge component 4 by 180°, remove hinge pin 5, turn by 180° and replace, mind the locking facility. Mount both parts in the hinge bq: slide the pin into the door mounting through the hinge, tilt in the hinge component, slide up and attach with screw 3.

WAlign the door flush with the body of the appliance using the slot on the hinge bq, then tighten screw 3.

WAttach the plinth panel 1 and click into place by pressing.

WWith the door open, insert the cover 2 in the plinth panel at the front and click into place at the back.

WTransfer* door handles br and plugs bt. With the door open, carefully lift out the pressure plates* bs at the front and slide away; unscrew handle using a Torx® or Phillips screwdriver*.

Insertion into row of kitchen units

Fig. U. The appliance can be installed in a row of kitchen units. To adapt the height of the appliance to the surround- ing furniture a top unit 1 can be added.

A gap of at least 50 mm depth must be provided behind and along the entire width of this unit so as to ensure sufficient ventilation. The area of ventilation underneath the ceiling should be at least 300 cm2. The greater the area the more economically the appliance will run.

WWhen installing with standard kitchen units (max. depth 580 mm), the appliance can be set up right next to the kitchen unit. The door protrudes 34 mm from the side of the kitchen unit and 51 mm at the front. This enables it to be opened and closed without difficulty.

WWhen setting up the appliance next to a wall 4, a mini- mum distance of 36 mm must be provided on the hinge side between the appliance and the wall (for the handle when the door is open).

1 top unit | 3 kitchen unit side panel |

2 refrigerator/freezer | 4 wall |

| 597 | 631 |

|

| [mm] |

|

| 614 |

|

|

|

| |

| 644 |

|

|

|

| |

|

| 1179 |

|

|

|

|

| 1841 |

|

|

|

|

|

S | 56, |

|

| 1 | 0 |

|

5 |

|

|

|

| ||

| I | II |

|

| 9 Torx | 25 |

| 8 |

| 25 | 20 | ||

| 8 |

|

|

|

| |

8 | 7 | 8 |

|

| 7 |

|

SW5 |

|

|

|

| ||

|

|

| SW5 | |||

|

|

|

| |||

| 9 | 21 |

|

|

|

| 9 | |

|

|

|

|

|

| |||

| 11 12 |

|

|

|

|

|

|

|

|

|

|

|

| 1 |

|

|

|

|

| 20 | 25 |

| 8 | 25 | 20 | |

|

|

|

| 0° | ||||

|

|

|

|

|

|

|

| |

* |

|

|

|

|

|

|

|

|

10 | 6 |

| 9 |

|

|

|

| 21 |

|

|

|

|

|

|

|

| |

13 |

| 5 |

| 14 |

|

|

|

|

2 |

|

|

|

|

|

| ||

|

|

|

|

|

|

|

| |

|

| 4 |

|

|

|

| 18 * | |

15 |

| 3 | 17* | 16* |

|

| ||

|

|

|

|

| ||||

|

|

|

|

|

| |||

Torx![]() 15

15

1

13

15

GB

T

T1

All types and models are subject to continuous improvement and the manufacturer therefore reserves the right to make modifications in the shape, equipment and technology.

1

2

3

U4

min. |

| . |

|

300 cm | 2 | 0 | |

|

| ||

|

| 5 | |

|

| in |

|

|

| m |

|

| 1 |

|

|

| 3 |

|

|

6 |

|

| |

0 8 5

ca. 36

[mm]

BN/BNes...6 | 21 |