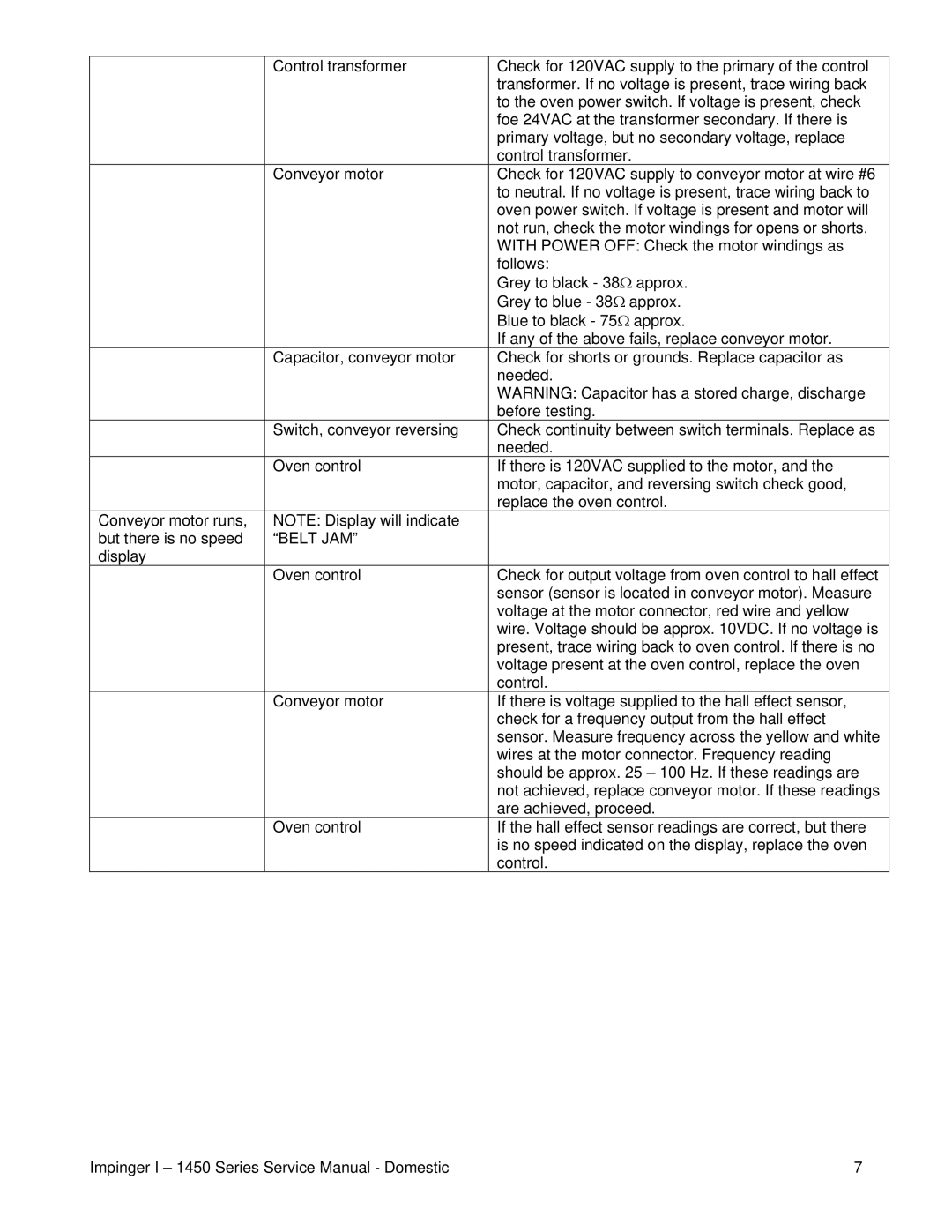

| Control transformer | Check for 120VAC supply to the primary of the control |

|

| transformer. If no voltage is present, trace wiring back |

|

| to the oven power switch. If voltage is present, check |

|

| foe 24VAC at the transformer secondary. If there is |

|

| primary voltage, but no secondary voltage, replace |

|

| control transformer. |

| Conveyor motor | Check for 120VAC supply to conveyor motor at wire #6 |

|

| to neutral. If no voltage is present, trace wiring back to |

|

| oven power switch. If voltage is present and motor will |

|

| not run, check the motor windings for opens or shorts. |

|

| WITH POWER OFF: Check the motor windings as |

|

| follows: |

|

| Grey to black - 38Ω approx. |

|

| Grey to blue - 38Ω approx. |

|

| Blue to black - 75Ω approx. |

|

| If any of the above fails, replace conveyor motor. |

| Capacitor, conveyor motor | Check for shorts or grounds. Replace capacitor as |

|

| needed. |

|

| WARNING: Capacitor has a stored charge, discharge |

|

| before testing. |

| Switch, conveyor reversing | Check continuity between switch terminals. Replace as |

|

| needed. |

| Oven control | If there is 120VAC supplied to the motor, and the |

|

| motor, capacitor, and reversing switch check good, |

|

| replace the oven control. |

Conveyor motor runs, | NOTE: Display will indicate |

|

but there is no speed | “BELT JAM” |

|

display |

|

|

| Oven control | Check for output voltage from oven control to hall effect |

|

| sensor (sensor is located in conveyor motor). Measure |

|

| voltage at the motor connector, red wire and yellow |

|

| wire. Voltage should be approx. 10VDC. If no voltage is |

|

| present, trace wiring back to oven control. If there is no |

|

| voltage present at the oven control, replace the oven |

|

| control. |

| Conveyor motor | If there is voltage supplied to the hall effect sensor, |

|

| check for a frequency output from the hall effect |

|

| sensor. Measure frequency across the yellow and white |

|

| wires at the motor connector. Frequency reading |

|

| should be approx. 25 – 100 Hz. If these readings are |

|

| not achieved, replace conveyor motor. If these readings |

|

| are achieved, proceed. |

| Oven control | If the hall effect sensor readings are correct, but there |

|

| is no speed indicated on the display, replace the oven |

|

| control. |

Impinger I – 1450 Series Service Manual - Domestic | 7 |