OPERATION | ||

|

|

|

CONTROLS AND SETTINGS

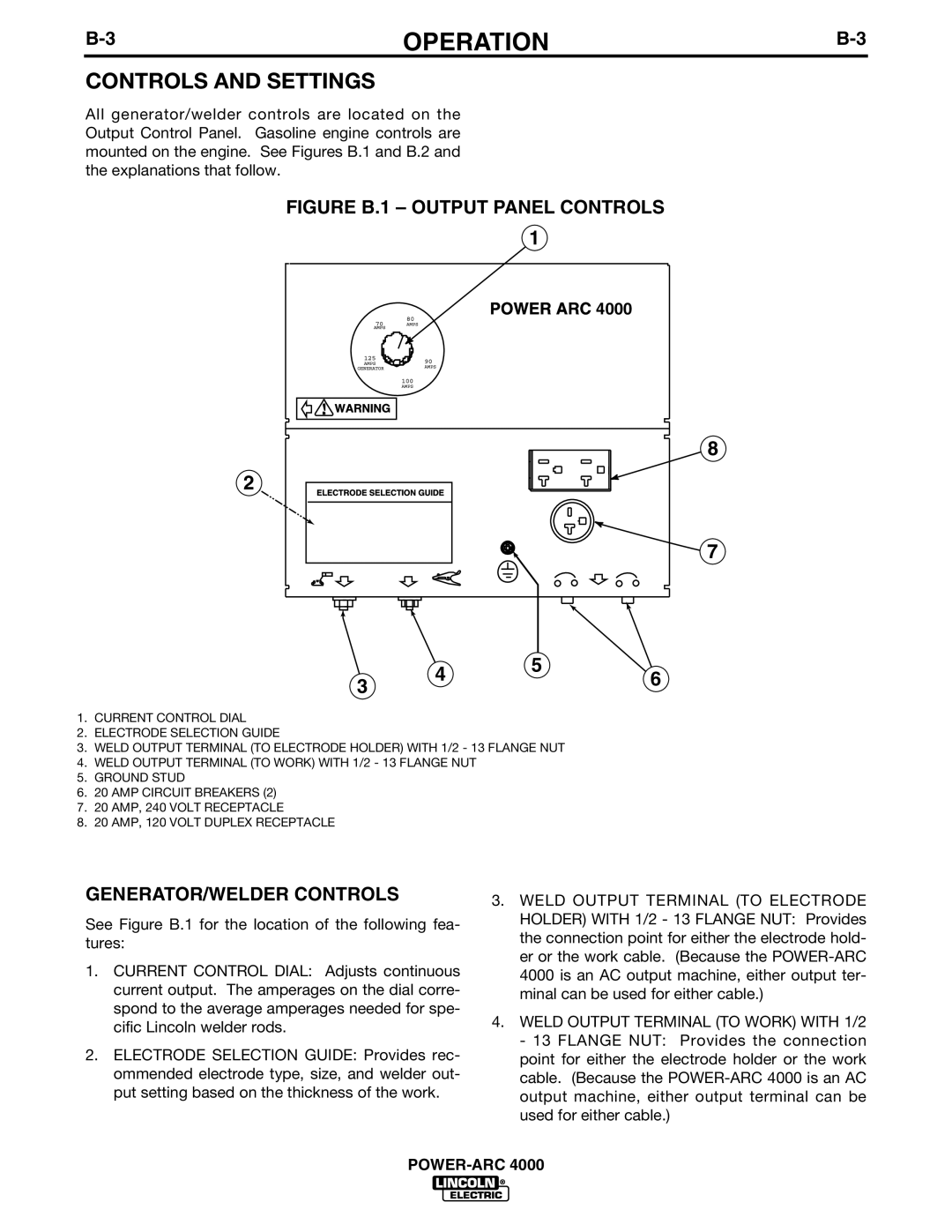

All generator/welder controls are located on the Output Control Panel. Gasoline engine controls are mounted on the engine. See Figures B.1 and B.2 and the explanations that follow.

FIGURE B.1 – OUTPUT PANEL CONTROLS

1

POWER ARC 4000

80

70AMPS

AMPS

125

AMPS90

GENERATORAMPS

100

AMPS

WARNING

2

ELECTRODE SELECTION GUIDE

8

7

3

4

5

6

1.CURRENT CONTROL DIAL

2.ELECTRODE SELECTION GUIDE

3.WELD OUTPUT TERMINAL (TO ELECTRODE HOLDER) WITH 1/2 - 13 FLANGE NUT

4.WELD OUTPUT TERMINAL (TO WORK) WITH 1/2 - 13 FLANGE NUT

5.GROUND STUD

6.20 AMP CIRCUIT BREAKERS (2)

7.20 AMP, 240 VOLT RECEPTACLE

8.20 AMP, 120 VOLT DUPLEX RECEPTACLE

GENERATOR/WELDER CONTROLS

See Figure B.1 for the location of the following fea- tures:

1.CURRENT CONTROL DIAL: Adjusts continuous current output. The amperages on the dial corre- spond to the average amperages needed for spe- cific Lincoln welder rods.

2.ELECTRODE SELECTION GUIDE: Provides rec- ommended electrode type, size, and welder out- put setting based on the thickness of the work.

3.WELD OUTPUT TERMINAL (TO ELECTRODE HOLDER) WITH 1/2 - 13 FLANGE NUT: Provides the connection point for either the electrode hold- er or the work cable. (Because the

4.WELD OUTPUT TERMINAL (TO WORK) WITH 1/2 - 13 FLANGE NUT: Provides the connection point for either the electrode holder or the work cable. (Because the