OPERATION | ||

|

|

|

In some instances a

| (b) | Scrap steel |

(a) | (c) |

Three ways to prepare plates where complete penetration is necessary.

On sections where only a sealed joint is required and strength is not important, the joint may be welded after slightly veeing out the seam as shown in figure (d) below.

(d) | (e) |

Single and double beads, with and without beveling for tight, partial strength joints.

Selecting Electrodes

Which electrode is best for the particular job . . . how do you use it? These are important questions because the cost, quality, and appearance of your work depends on proper electrode selection and appli- cation. MILD STEEL ELECTRODES may be classi- fied into the following groups:

Out-of-Position Group (AWS E6011)

This group includes electrodes which have a snappy, deep penetrating arc and fast freezing deposits.

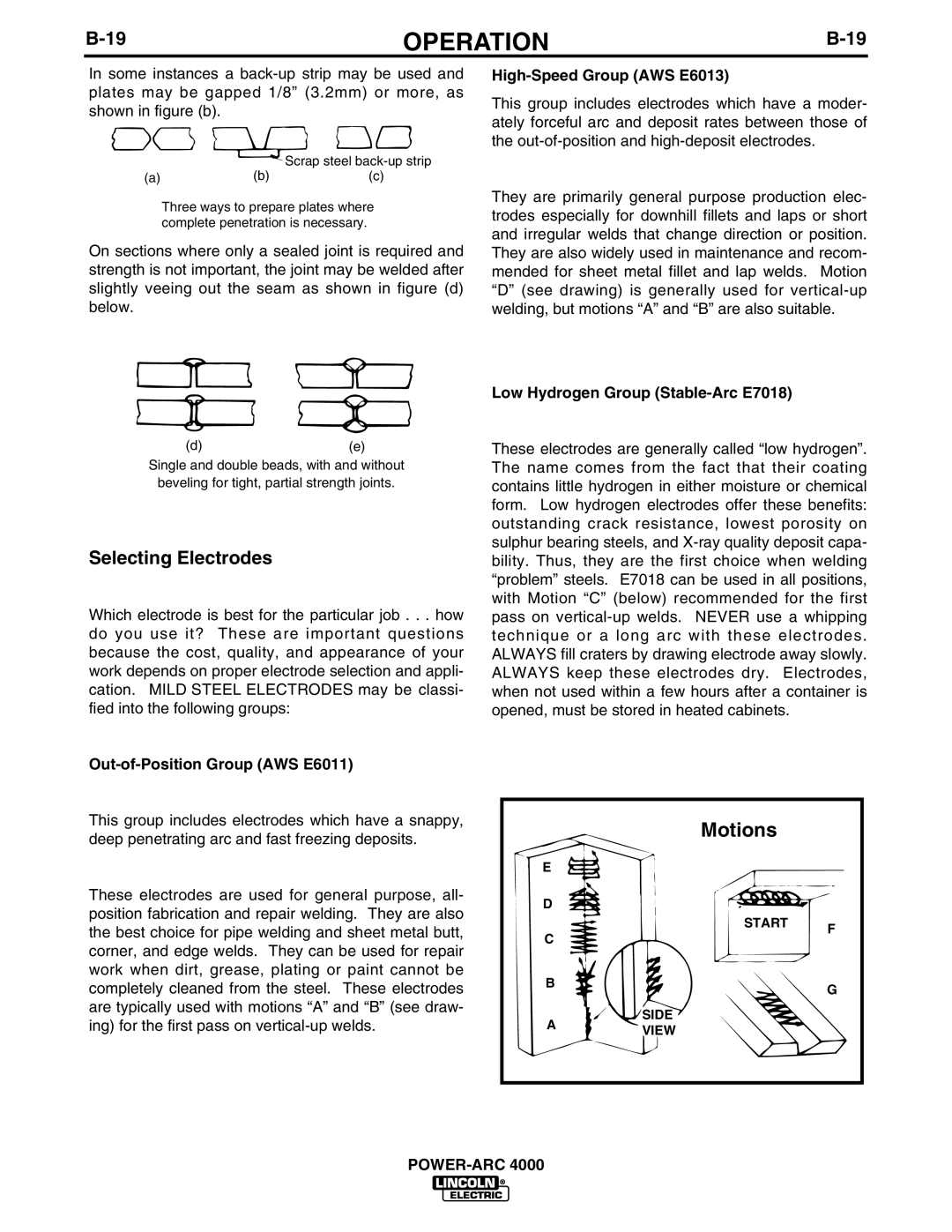

These electrodes are used for general purpose, all- position fabrication and repair welding. They are also the best choice for pipe welding and sheet metal butt, corner, and edge welds. They can be used for repair work when dirt, grease, plating or paint cannot be completely cleaned from the steel. These electrodes are typically used with motions “A” and “B” (see draw- ing) for the first pass on

High-Speed Group (AWS E6013)

This group includes electrodes which have a moder- ately forceful arc and deposit rates between those of the

They are primarily general purpose production elec- trodes especially for downhill fillets and laps or short and irregular welds that change direction or position. They are also widely used in maintenance and recom- mended for sheet metal fillet and lap welds. Motion “D” (see drawing) is generally used for

Low Hydrogen Group (Stable-Arc E7018)

These electrodes are generally called “low hydrogen”. The name comes from the fact that their coating contains little hydrogen in either moisture or chemical form. Low hydrogen electrodes offer these benefits: outstanding crack resistance, lowest porosity on sulphur bearing steels, and

|

|

| Motions |

|

E |

|

|

|

|

D |

|

| START | F |

C |

|

| ||

|

|

| ||

|

|

|

| |

B |

|

|

| G |

|

|

|

| |

A | SIDE |

| ||

VIEW |

| |||

|

| |||

|

|

|

|

|