A CLOSER LOOK

PERFORMANCE

Mechanical Filtering Technique

The LongLife® filter has a surface area of 50 m2 (164 ft2), making it one of the largest disposable filter cartridges in its class for collection of weld fume particulate. The combination of this with an ExtraCoat® pretreatment and the unique

A pressure differential filter indicator located at front of unit, moves gradually from white to red as the filter becomes saturated with welding fume particulate, indicating when system maintenance and filter replacement is necessary. The washable aluminum prefilter sits inside the LongLife® filter to remove the large particulates and pro- vide spark entrapment.

Extraction Arms

No matter if you are working in a small work station, under a low ceiling, or in a large fabrication area, one of Lincoln Electric’s® various fume extraction arms for welding will work for you. The flexible extraction arms are built the Lincoln®

The arms come equipped with the 360° rotatable hood for optimal positioning to welding source. This allows a larger work envelope with less repositioning of the arm and increased operator visibility. With the extraction arm correctly positioned, the welding fume par- ticulate can be effectively drawn away from the operator’s breathing zone, as well as eliminate the residual fume particulate that often rises and hovers within the facility.

With a unique

LongLife® Filter | LongLife® Filter inside of unit | ||

|

|

|

|

|

|

|

|

Rotatable Hood

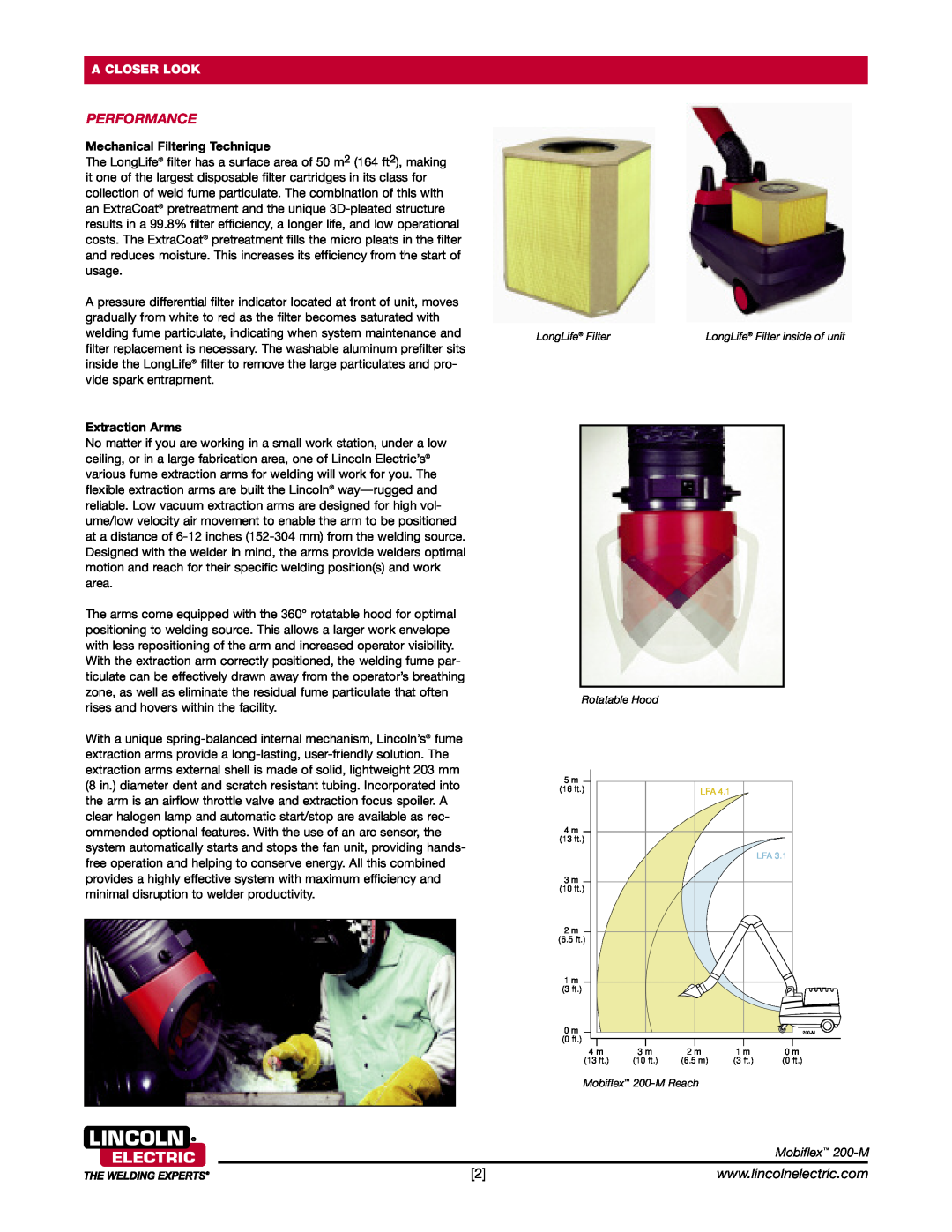

5 m |

|

|

|

|

(16 ft.) |

| LFA 4.1 |

|

|

|

|

|

| |

4 m |

|

|

|

|

(13 ft.) |

|

|

|

|

|

|

|

| LFA 3.1 |

3 m |

|

|

|

|

(10 ft.) |

|

|

|

|

2 m |

|

|

|

|

(6.5 ft.) |

|

|

|

|

1 m |

|

|

|

|

(3 ft.) |

|

|

|

|

0 m |

|

|

| |

(0 ft.) |

|

|

|

|

4 m | 3 m | 2 m | 1 m | 0 m |

(13 ft.) | (10 ft.) | (6.5 m) | (3 ft.) | (0 ft.) |

Mobiflex™

Mobiflex™ 200-M

[2] | www.lincolnelectric.com |