|

| INSTALLATION |

| |||||

|

|

|

|

|

|

|

|

|

| b. Remove the molded gas plug fitting on the side of the |

|

|

| ||||

| feeder end handle and replace it with the barbed brass fit- |

|

|

|

| |||

| ting provided in the kit. The included wrench will fit both |

|

|

|

| |||

| the gas plug and barbed fitting. |

|

|

|

|

|

| |

| c. Attach the phone plug connector of the gun control cable |

|

|

|

| |||

| provided to the trigger connector on the front of the |

|

|

|

| |||

| Hobart feeder. |

|

|

|

|

|

| |

|

|

|

|

| ||||

|

|

|

|

|

| |||

| d. Place one tubing clamp onto each end of the flexible tub- | Hobart Series 2000 Feeders and Lincoln 10 Series Feeders) |

| |||||

| ing provided, approximately 2” (51 mm) in from each end. |

|

|

|

| |||

| Slide one end of the tubing onto the barbed connector on |

| a. Remove brass cable connector (see Figure B.1) from the |

| ||||

| the feeder end cable handle (step b) and move the clamp |

| connector kit and screw it onto the feeder end of the gun |

| ||||

| down near the end of the tube to assure a good gas seal. |

| cable. Tighten the connection with the wrench provided. |

| ||||

|

|

|

|

|

| b. Check that the molded gas plug fitting is sealing the gas |

| |

|

|

|

|

|

|

| ||

|

|

|

|

|

| fitting hole in the side of the feeder end handle. |

|

|

|

|

|

|

|

| c. Attach the gun control cable provided to the trigger con- |

| |

|

|

|

|

|

| nector on the front of the wire feeder. |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

| ||

| a. Remove brass cable connector (see Figure B.1) from the |

|

|

|

| |||

|

|

|

|

| ||||

| cable. Tighten the connection with the wrench provided. |

|

|

|

| |||

b. Check that the molded gas plug fitting is sealing the gas

fitting hole in the side of the feeder end handle. |

| ||

| |||

c. For |

| ||

to be made at a terminal strip located within the machine |

| ||

| |||

|

| ||

provided. Connect the terminated leads to the terminal |

|

| |

strip. For a machine that requires a | |||

| |||

cable connection, continue to use the |

| ||

cable provided with the |

| ||

assembly. Connect the |

| ||

receptacle on the machine. |

| ||

|

|

| |

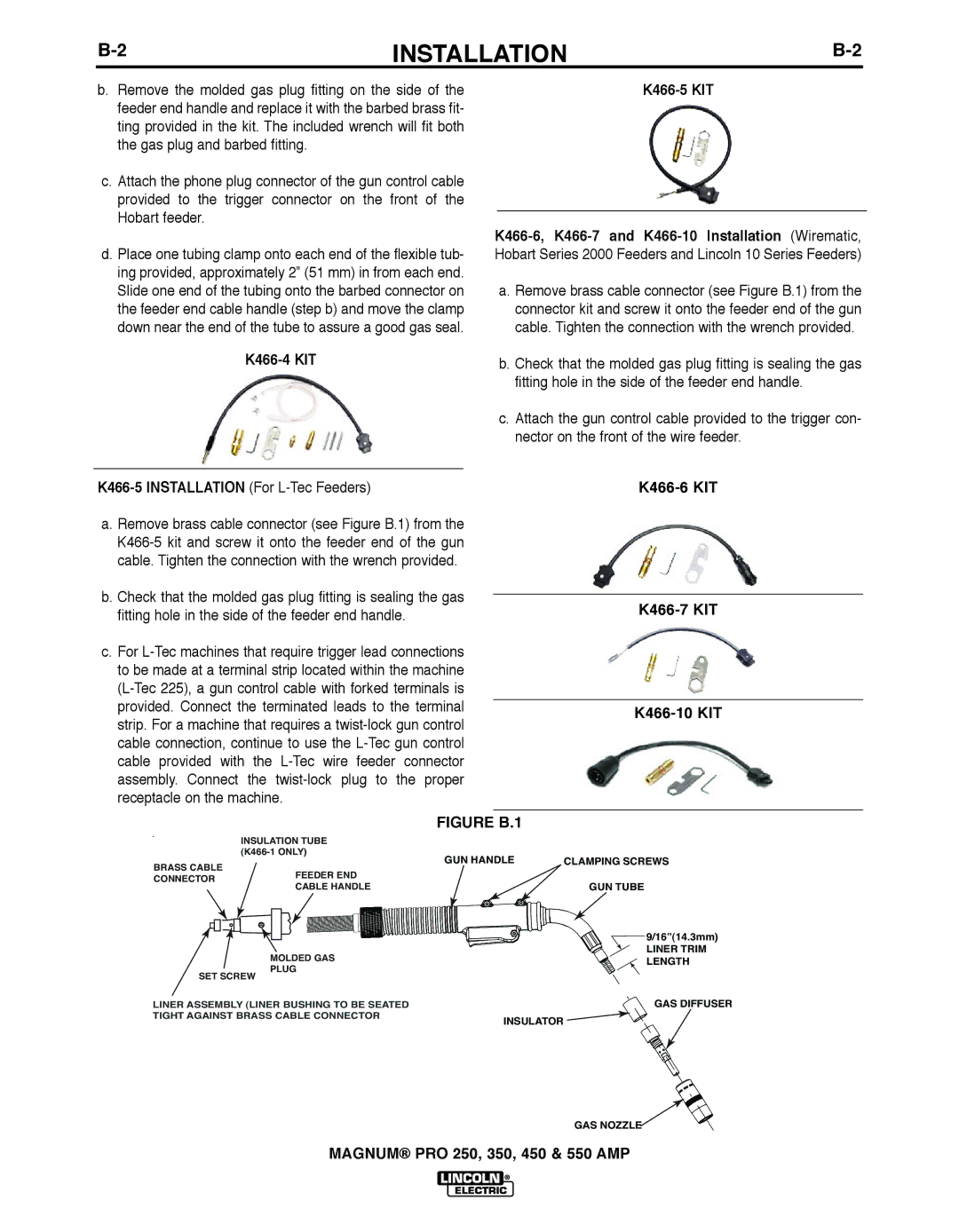

FIGURE B.1 |

| ||

INSULATION TUBE

BRASS CABLE

CONNECTORFEEDER END CABLE HANDLE

| MOLDED GAS |

SET SCREW | PLUG |

|

LINER ASSEMBLY (LINER BUSHING TO BE SEATED TIGHT AGAINST BRASS CABLE CONNECTOR

GUN HANDLE | CLAMPING SCREWS |

| GUN TUBE |

| 9/16”(14.3mm) |

| LINER TRIM |

| LENGTH |

| GAS DIFFUSER |

INSULATOR |

|

GAS NOZZLE![]()

MAGNUM® PRO 250, 350, 450 & 550 AMP