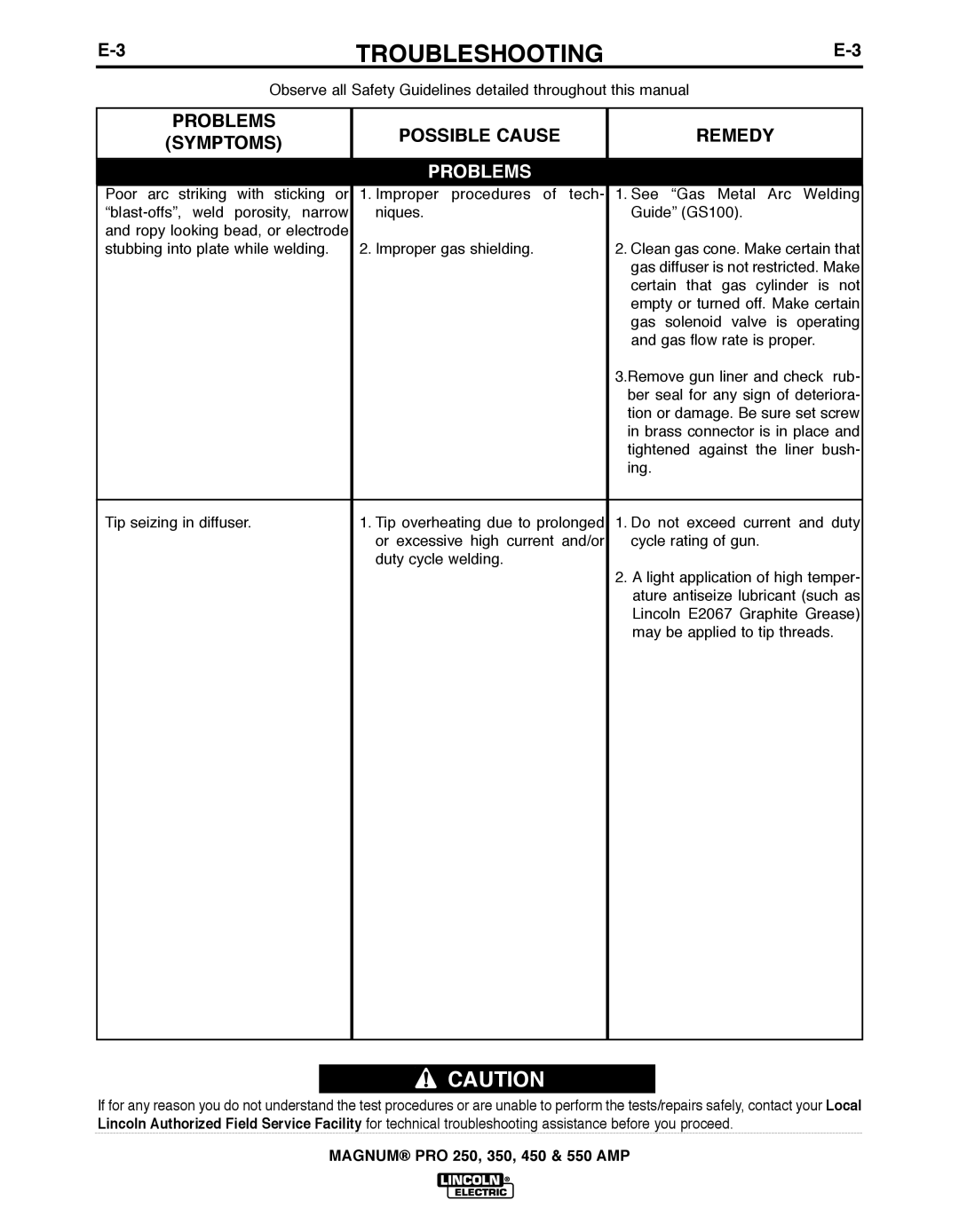

TROUBLEShOOTING | ||

| Observe all Safety Guidelines detailed throughout this manual |

|

PROBLEMS

(SYMPTOMS)

POSSIBLE CAUSE

REMEDY

PROBLEMS

Poor arc striking with sticking or | 1. Improper procedures of tech- | 1. See “Gas Metal Arc Welding |

niques. | Guide” (GS100). | |

and ropy looking bead, or electrode |

|

|

stubbing into plate while welding. | 2. Improper gas shielding. | 2. Clean gas cone. Make certain that |

|

| gas diffuser is not restricted. Make |

|

| certain that gas cylinder is not |

|

| empty or turned off. Make certain |

|

| gas solenoid valve is operating |

|

| and gas flow rate is proper. |

|

| 3.Remove gun liner and check rub- |

|

| ber seal for any sign of deteriora- |

|

| tion or damage. Be sure set screw |

|

| in brass connector is in place and |

|

| tightened against the liner bush- |

|

| ing. |

|

|

|

Tip seizing in diffuser. | 1. Tip overheating due to prolonged | 1. Do not exceed current and duty |

| or excessive high current and/or | cycle rating of gun. |

| duty cycle welding. |

|

|

| 2. A light application of high temper- |

|

| ature antiseize lubricant (such as |

|

| Lincoln E2067 Graphite Grease) |

|

| may be applied to tip threads. |

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

MAGNUM® PRO 250, 350, 450 & 550 AMP