|

|

|

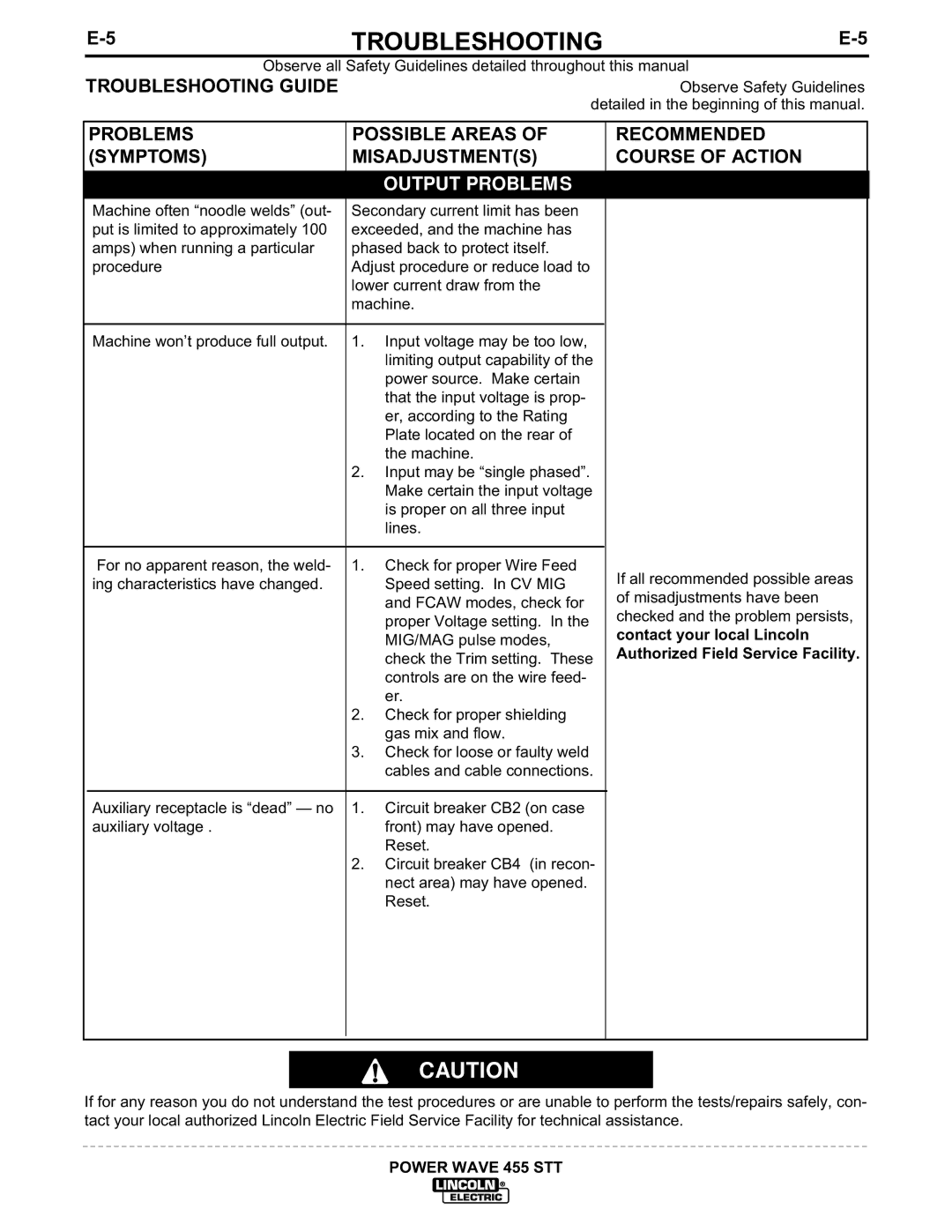

| TROUBLESHOOTING |

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Observe all Safety Guidelines detailed throughout this manual | ||||||||

| TROUBLESHOOTING GUIDE |

|

|

|

|

| Observe Safety Guidelines | |||||

|

|

|

|

|

|

|

| detailed in the beginning of this manual. | ||||

|

|

|

|

|

|

|

|

|

|

| ||

|

| PROBLEMS |

| POSSIBLE AREAS OF |

| RECOMMENDED | ||||||

|

| (SYMPTOMS) |

| MISADJUSTMENT(S) |

| COURSE OF ACTION | ||||||

|

|

|

|

|

|

|

| OUTPUT PROBLEMS |

|

|

| |

|

|

|

|

|

|

|

|

|

|

| ||

|

|

| Machine often “noodle welds” (out- | Secondary current limit has been |

|

|

| |||||

|

|

| put is limited to approximately 100 |

|

| exceeded, and the machine has |

|

|

|

| ||

|

|

| amps) when running a particular |

|

| phased back to protect itself. |

|

|

|

| ||

|

|

| procedure |

|

| Adjust procedure or reduce load to |

|

|

|

| ||

|

|

|

|

|

|

| lower current draw from the |

|

|

|

| |

|

|

|

|

|

|

| machine. |

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

| ||

|

|

| Machine won’t produce full output. |

|

| 1. Input voltage may be too low, |

|

|

|

| ||

|

|

|

|

|

|

|

| limiting output capability of the |

|

|

|

|

|

|

|

|

|

|

|

| power source. Make certain |

|

|

|

|

|

|

|

|

|

|

|

| that the input voltage is prop- |

|

|

|

|

|

|

|

|

|

|

|

| er, according to the Rating |

|

|

|

|

|

|

|

|

|

|

|

| Plate located on the rear of |

|

|

|

|

|

|

|

|

|

|

|

| the machine. |

|

|

|

|

|

|

|

|

|

|

| 2. | Input may be “single phased”. |

|

|

|

|

|

|

|

|

|

|

|

| Make certain the input voltage |

|

|

|

|

|

|

|

|

|

|

|

| is proper on all three input |

|

|

|

|

|

|

|

|

|

|

|

| lines. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

| For no apparent reason, the weld- |

|

| 1. | Check for proper Wire Feed |

|

| If all recommended possible areas |

| |

|

|

| ing characteristics have changed. |

|

|

| Speed setting. In CV MIG |

|

|

| ||

|

|

|

|

|

|

|

| of misadjustments have been |

| |||

|

|

|

|

|

|

|

| and FCAW modes, check for |

|

|

| |

|

|

|

|

|

|

|

|

|

| checked and the problem persists, |

| |

|

|

|

|

|

|

|

| proper Voltage setting. In the |

|

|

| |

|

|

|

|

|

|

|

|

|

| contact your local Lincoln |

| |

|

|

|

|

|

|

|

| MIG/MAG pulse modes, |

|

|

| |

|

|

|

|

|

|

|

| check the Trim setting. These |

|

| Authorized Field Service Facility. |

|

|

|

|

|

|

|

|

| controls are on the wire feed- |

|

|

|

|

|

|

|

|

|

|

|

| er. |

|

|

|

|

|

|

|

|

|

|

| 2. | Check for proper shielding |

|

|

|

|

|

|

|

|

|

|

|

| gas mix and flow. |

|

|

|

|

|

|

|

|

|

|

| 3. | Check for loose or faulty weld |

|

|

|

|

|

|

|

|

|

|

|

| cables and cable connections. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

| Auxiliary receptacle is “dead” — no |

|

| 1. Circuit breaker CB2 (on case |

|

|

|

| ||

|

|

| auxiliary voltage . |

|

|

| front) may have opened. |

|

|

|

| |

|

|

|

|

|

|

|

| Reset. |

|

|

|

|

|

|

|

|

|

|

| 2. | Circuit breaker CB4 (in recon- |

|

|

|

|

|

|

|

|

|

|

|

| nect area) may have opened. |

|

|

|

|

|

|

|

|

|

|

|

| Reset. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, con- tact your local authorized Lincoln Electric Field Service Facility for technical assistance.