INSTALLATION | ||

|

|

|

Read entire installation section before starting installation.

SAFETY PRECAUTIONS

![]() WARNING

WARNING

ELECTRIC SHOCK can kill.

•Only qualified personnel should perform this installation.

•Turn the input power OFF at the discon- nect switch or fuse box before working on this equipment.

•Turn the Power switch on the

•Do not touch electrically hot parts.

•Always connect the Idealarc

SELECT SUITABLE LOCATION

Place the welder where clean cooling air can freely circulate in through the side louvers and out through the rear louvers. Dirt, dust or any foreign material that can be drawn into the welder should be kept at a minimum. Failure to observe these precautions can result in excessive operating temperatures and nuisance

STACKING

The

TILTING

Do not place the machine on a surface that is inclined enough to create a risk of the machine falling over.

INPUT CONNECTIONS

Be sure the voltage, phase, and frequency of the input power is as specified on the welder nameplate.

Gain access to the input reconnect panel by removing the right case side of the

Have a qualified electrician connect the input leads to L1, L2, and L3 of the input reconnect panel in accor- dance with the National Electrical Code, all local codes, and the connection diagram located on the inside of the right case side. Use a three phase line.

The frame of the welder must be grounded. A ground

terminal marked with the symbol ![]() located on the base of the machine is provided for this purpose. See the National Electrical Code for details on proper grounding methods.

located on the base of the machine is provided for this purpose. See the National Electrical Code for details on proper grounding methods.

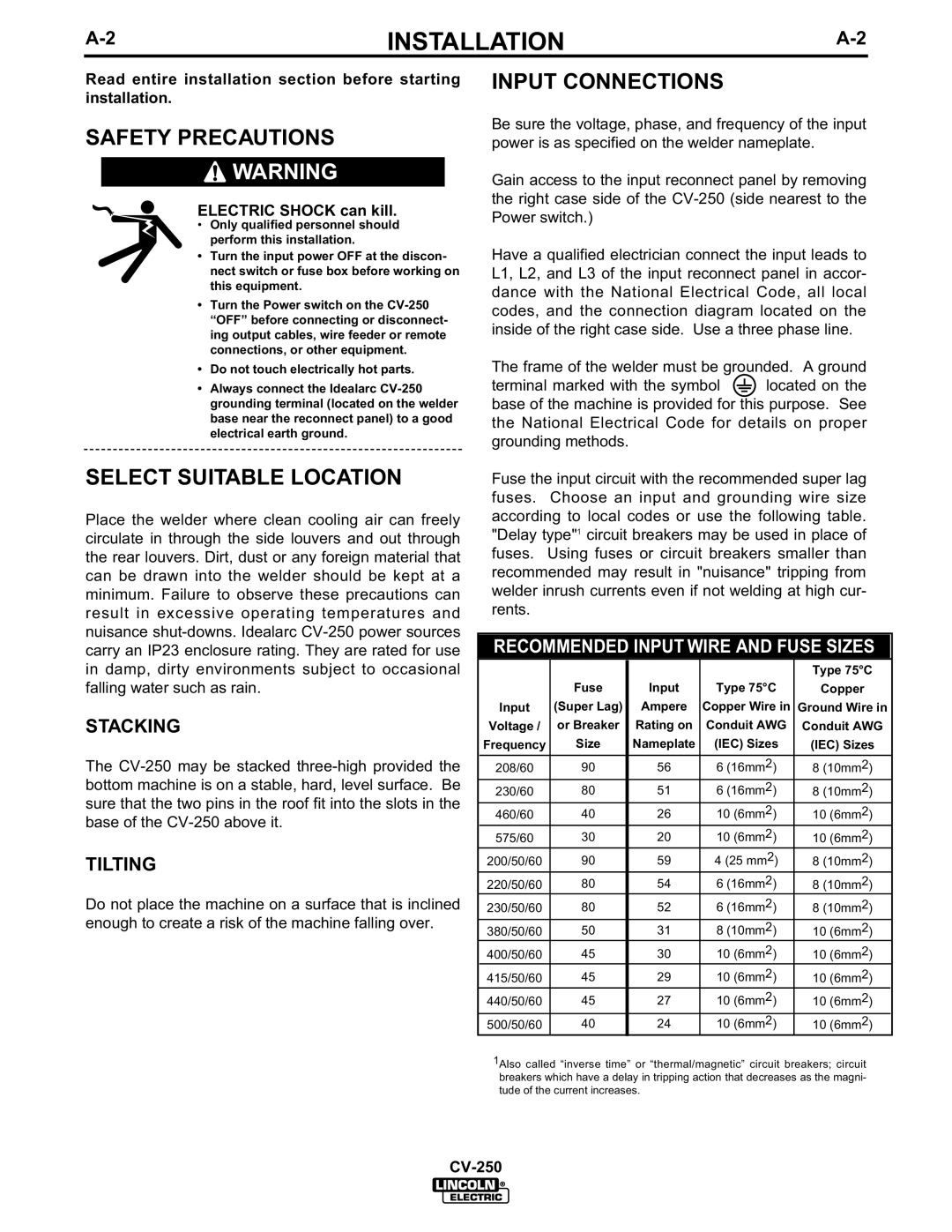

Fuse the input circuit with the recommended super lag fuses. Choose an input and grounding wire size according to local codes or use the following table. "Delay type"1 circuit breakers may be used in place of fuses. Using fuses or circuit breakers smaller than recommended may result in "nuisance" tripping from welder inrush currents even if not welding at high cur- rents.

RECOMMENDED INPUT WIRE AND FUSE SIZES

|

|

|

|

|

|

|

|

|

|

|

|

|

| Type 75°C |

|

|

|

| Fuse | Input | Type 75°C | Copper |

|

|

| Input | (Super Lag) | Ampere | Copper Wire in | Ground Wire in |

|

|

| Voltage / | or Breaker | Rating on | Conduit AWG | Conduit AWG |

|

|

| Frequency | Size | Nameplate | (IEC) Sizes | (IEC) Sizes |

|

|

| 208/60 | 90 | 56 | 6 (16mm2) | 8 (10mm2) |

|

|

| 230/60 | 80 | 51 | 6 (16mm2) | 8 (10mm2) |

|

|

| 460/60 | 40 | 26 | 10 (6mm2) | 10 (6mm2) |

|

|

| 575/60 | 30 | 20 | 10 (6mm2) | 10 (6mm2) |

|

|

| 200/50/60 | 90 | 59 | 4 (25 mm2) | 8 (10mm2) |

|

|

| 220/50/60 | 80 | 54 | 6 (16mm2) | 8 (10mm2) |

|

|

| 230/50/60 | 80 | 52 | 6 (16mm2) | 8 (10mm2) |

|

|

| 380/50/60 | 50 | 31 | 8 (10mm2) | 10 (6mm2) |

|

|

| 400/50/60 | 45 | 30 | 10 (6mm2) | 10 (6mm2) |

|

|

| 415/50/60 | 45 | 29 | 10 (6mm2) | 10 (6mm2) |

|

|

| 440/50/60 | 45 | 27 | 10 (6mm2) | 10 (6mm2) |

|

|

| 500/50/60 | 40 | 24 | 10 (6mm2) | 10 (6mm2) |

|

1Also called “inverse time” or “thermal/magnetic” circuit breakers; circuit breakers which have a delay in tripping action that decreases as the magni- tude of the current increases.