INSTALLATION | ||

|

|

|

LOCATION

![]() WARNING

WARNING

FALLING EQUIPMENT can cause injury.

•Do not lift this machine using lift bail if it is equipped with a heavy

•accessory such as trailer or gas cylinder.

•Lift only with equipment of adequate lifting capacity.

•Be sure machine is stable when lifting.

Install the welder in a dry location where there is a free circulation of air in through the front louvers and out the back of the case. A location which minimizes the amount of smoke and dirt drawn into the front louvers reduces the chance of dirt accumulation that can block air passages, causing overheating and nuisance shut- down of the machine.

INPUT WIRING

![]() WARNING

WARNING

ELECTRIC SHOCK can kill.

• Have an electrician install and ser- vice this equipment.

•Turn the input power off at the fuse box before working on equipment.

•Do not touch electrically hot parts.

Welder is rated for 230/460/575V input and is shipped from the factory connected for 460V input. To change the connection, see the wiring or connection diagram pasted to the inside of the access panel in the case back.

Be sure the voltage, phase and frequency of the input power is as specified on the welder nameplate.

Have a qualified electrician remove the access panel in the case back and connect the three phase AC power to terminals L1, L2, L3 of the input contactor in accor- dance with the U. S. National Electrical Code, all local codes, and the wiring diagram located inside the machine.

The welder frame must be grounded. A stud marked with the symbol located on the floor of the input box is provided for this purpose. See the U.S. National Electrical Code for details on proper grounding meth- ods.

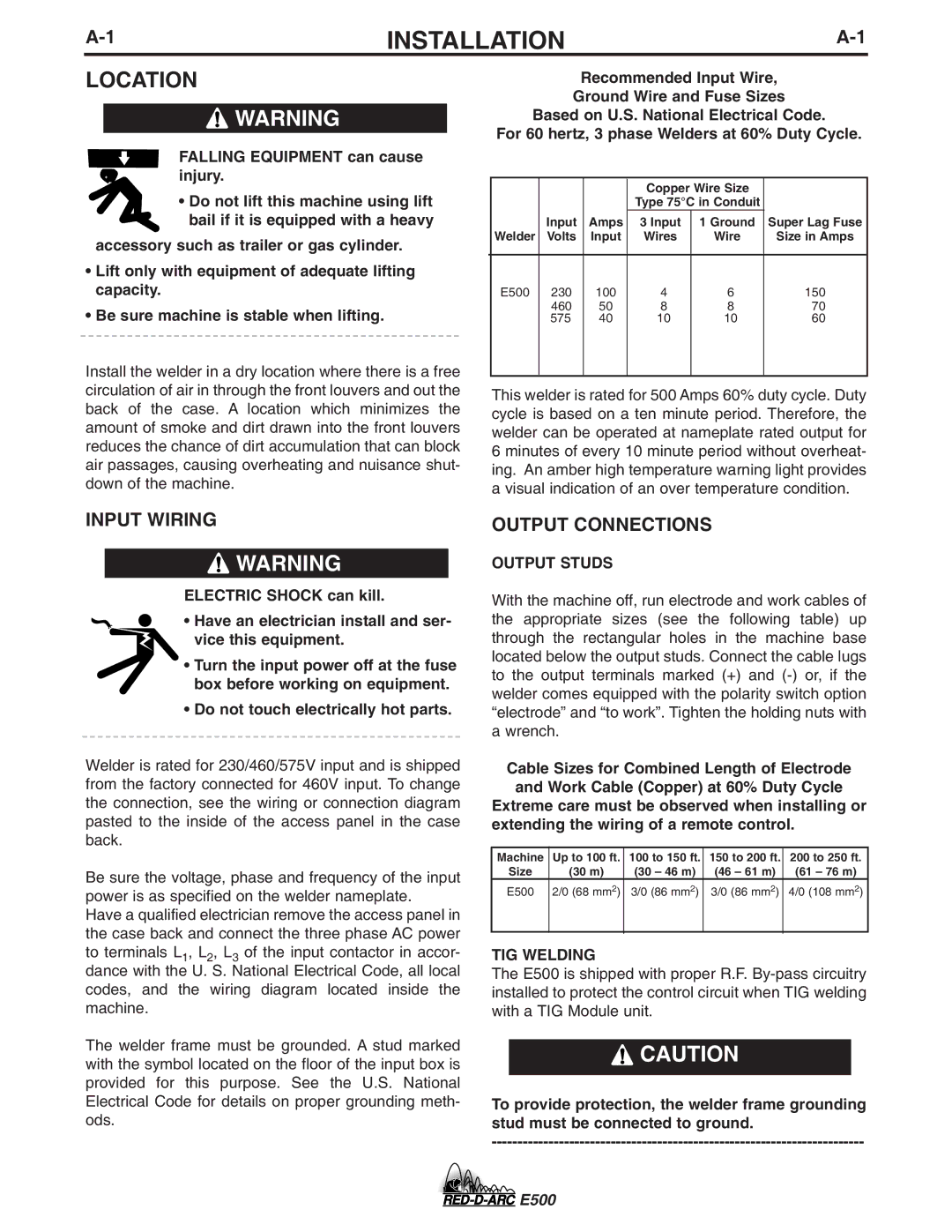

Recommended Input Wire,

Ground Wire and Fuse Sizes

Based on U.S. National Electrical Code.

For 60 hertz, 3 phase Welders at 60% Duty Cycle.

|

|

|

| Copper Wire Size |

|

| |

|

|

|

| Type 75°C in Conduit |

|

| |

|

| Input | Amps | 3 Input | 1 Ground |

| Super Lag Fuse |

| Welder | Volts | Input | Wires | Wire |

| Size in Amps |

|

|

|

|

|

|

|

|

| E500 | 230 | 100 | 4 | 6 | 150 | |

|

| 460 | 50 | 8 | 8 | 70 | |

|

| 575 | 40 | 10 | 10 | 60 | |

|

|

|

|

|

|

|

|

This welder is rated for 500 Amps 60% duty cycle. Duty cycle is based on a ten minute period. Therefore, the welder can be operated at nameplate rated output for 6 minutes of every 10 minute period without overheat- ing. An amber high temperature warning light provides a visual indication of an over temperature condition.

OUTPUT CONNECTIONS

OUTPUT STUDS

With the machine off, run electrode and work cables of the appropriate sizes (see the following table) up through the rectangular holes in the machine base located below the output studs. Connect the cable lugs to the output terminals marked (+) and

Cable Sizes for Combined Length of Electrode and Work Cable (Copper) at 60% Duty Cycle Extreme care must be observed when installing or

extending the wiring of a remote control.

Machine | Up to 100 ft. | 100 to 150 ft. | 150 to 200 ft. | 200 to 250 ft. |

Size | (30 m) | (30 – 46 m) | (46 – 61 m) | (61 – 76 m) |

E500 | 2/0 (68 mm2) | 3/0 (86 mm2) | 3/0 (86 mm2) | 4/0 (108 mm2) |

|

|

|

|

|

TIG WELDING

The E500 is shipped with proper R.F.

![]() CAUTION

CAUTION

To provide protection, the welder frame grounding stud must be connected to ground.

![]()

![]()

![]()

![]()

![]() E500

E500