CARTRIDGE OPERATION/FEATURES

Variable Shade Control

The shade can be adjusted from shade 9 to 13 based upon welding process or application (refer to Shade selection chart on page 6). The variable shade control knob is mounted to shell for external adjustment.

Sensitivity Control

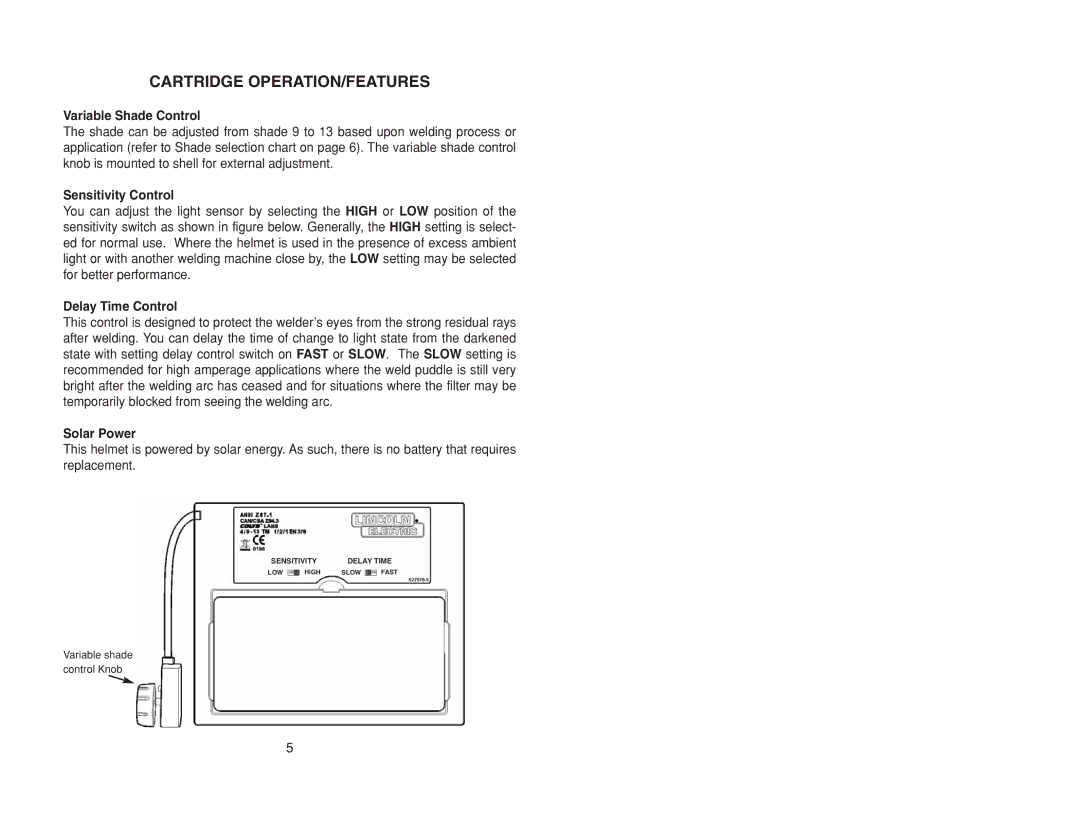

You can adjust the light sensor by selecting the HIGH or LOW position of the sensitivity switch as shown in figure below. Generally, the HIGH setting is select- ed for normal use. Where the helmet is used in the presence of excess ambient light or with another welding machine close by, the LOW setting may be selected for better performance.

Delay Time Control

This control is designed to protect the welder’s eyes from the strong residual rays after welding. You can delay the time of change to light state from the darkened state with setting delay control switch on FAST or SLOW. The SLOW setting is recommended for high amperage applications where the weld puddle is still very bright after the welding arc has ceased and for situations where the filter may be temporarily blocked from seeing the welding arc.

Solar Power

This helmet is powered by solar energy. As such, there is no battery that requires replacement.

SENSITIVITY | DELAY TIME |

LOW HIGH SLOW FAST

Variable shade control Knob

5