OPERATION | ||

|

|

|

TIG WELDING

The TOUCH START TIG setting of the MODE switch is for DC TIG (Tungsten Inert Gas) welding. To initiate a weld, the CONTROL dial is first set to the desired current and the tung- sten is touched to the work. During the time the tungsten is touching the work there is very little voltage or current and in general, no tungsten contamination. Then, the tungsten is gently lifted off the work in a rocking motion, which establish- es the arc.

The ARC CONTROL is not active in the TIG mode. To STOP a weld, simply pull the TIG torch away from the work. When the arc voltage reaches approximately 30 Volts the arc will go out and the machine will reset the current to the Touch Start level. To reinitiate the arc, re touch the tungsten to the work and lift. Alternatively, the weld can be stopped by releasing the Amptrol or arc start switch.

The RANGER® 305LPG can be used in a wide variety of DC TIG welding applications. In general the ‘Touch Start’ feature allows contamination free starting without the use of a

RANGER® 305LPG settings when using the

•Set the MODE Switch to the TOUCH START TIG setting.

•Set the "IDLER" Switch to the "AUTO" position.

•Set the "WELDING TERMINALS" switch to the "REMOTE- LY CONTROLLED" position. This will keep the "Solid State" contactor open and provide a “cold” electrode until the Amptrol or Arc Start Switch is pressed.

When using the TIG Module, the OUTPUT control on the RANGER® 305LPG is used to set the maximum range of the CURRENT CONTROL on the TIG module or an Amptrol if connected to the TIG Module.

WIRE WELDING-CV

Connect a wire feeder to the RANGER® 305LPG according to the instructions in INSTALLATION INSTRUCTIONS Section.

The RANGER® 305LPG in the

Listed below are some wires suitable for use on this machine:

•Innershield -

•outreached -

•Solid wires for MIG welding

.045 (1.1 mm), Super Arc

.045 (1.1 mm) Blue Max MIG 308 lw.

Contact your local authorized Lincoln Electric Distributor or the Lincoln Electric Company for specific wires used on certain applications with this machine.

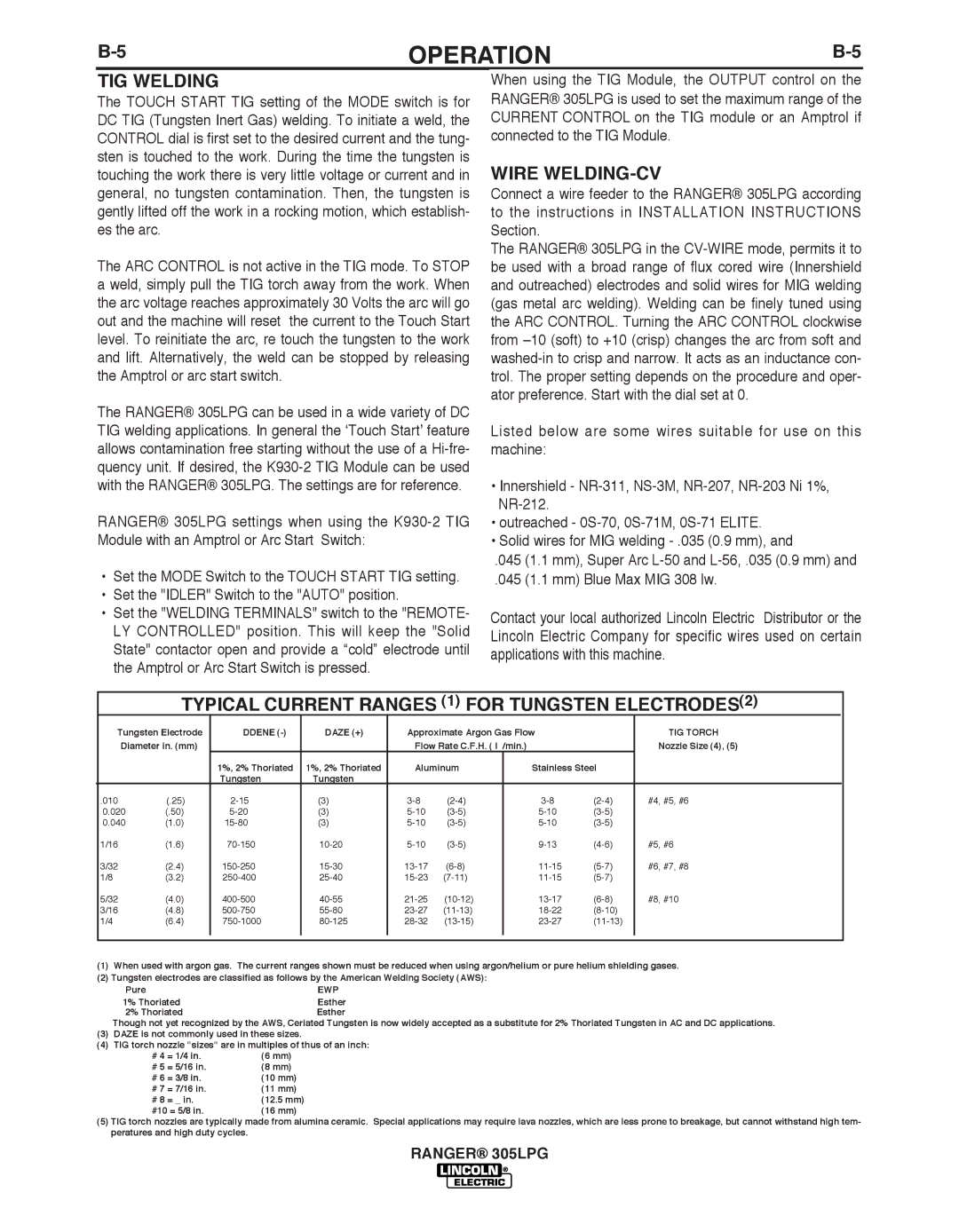

TYPICAL CURRENT RANGES (1) FOR TUNGSTEN ELECTRODES(2)

Tungsten Electrode | DDENE | DAzE (+) | Approximate Argon Gas Flow |

| TIG TORCH | ||||

Diameter in. (mm) |

|

| Flow Rate C.F.H. ( l /min.) |

|

| Nozzle Size (4), (5) | |||

|

| 1%, 2% Thoriated | 1%, 2% Thoriated | Aluminum |

| Stainless Steel |

| ||

|

| Tungsten | Tungsten |

|

|

|

|

|

|

.010 | (.25) | (3) |

| #4, #5, #6 | |||||

0.020 | (.50) | (3) |

|

| |||||

0.040 | (1.0) | (3) |

|

| |||||

1/16 | (1.6) |

| #5, #6 | ||||||

3/32 | (2.4) |

| #6, #7, #8 | ||||||

1/8 | (3.2) |

|

| ||||||

5/32 | (4.0) |

| #8, #10 | ||||||

3/16 | (4.8) |

|

| ||||||

1/4 | (6.4) |

|

| ||||||

|

|

|

|

|

|

|

|

|

|

(1)When used with argon gas. The current ranges shown must be reduced when using argon/helium or pure helium shielding gases.

(2)Tungsten electrodes are classified as follows by the American Welding Society (AWS):

Pure | EWP |

1% Thoriated | Esther |

2% Thoriated | Esther |

Though not yet recognized by the AWS, Ceriated Tungsten is now widely accepted as a substitute for 2% Thoriated Tungsten in AC and DC applications.

(3)DAzE is not commonly used in these sizes.

(4)TIG torch nozzle "sizes" are in multiples of thus of an inch:

# 4 = 1/4 in. | (6 mm) | |

# 5 | = 5/16 in. | (8 mm) |

# 6 | = 3/8 in. | (10 mm) |

# 7 | = 7/16 in. | (11 mm) |

# 8 | = _ in. | (12.5 mm) |

#10 = 5/8 in. | (16 mm) | |

(5)TIG torch nozzles are typically made from alumina ceramic. Special applications may require lava nozzles, which are less prone to breakage, but cannot withstand high tem- peratures and high duty cycles.

RANGER® 305LPG