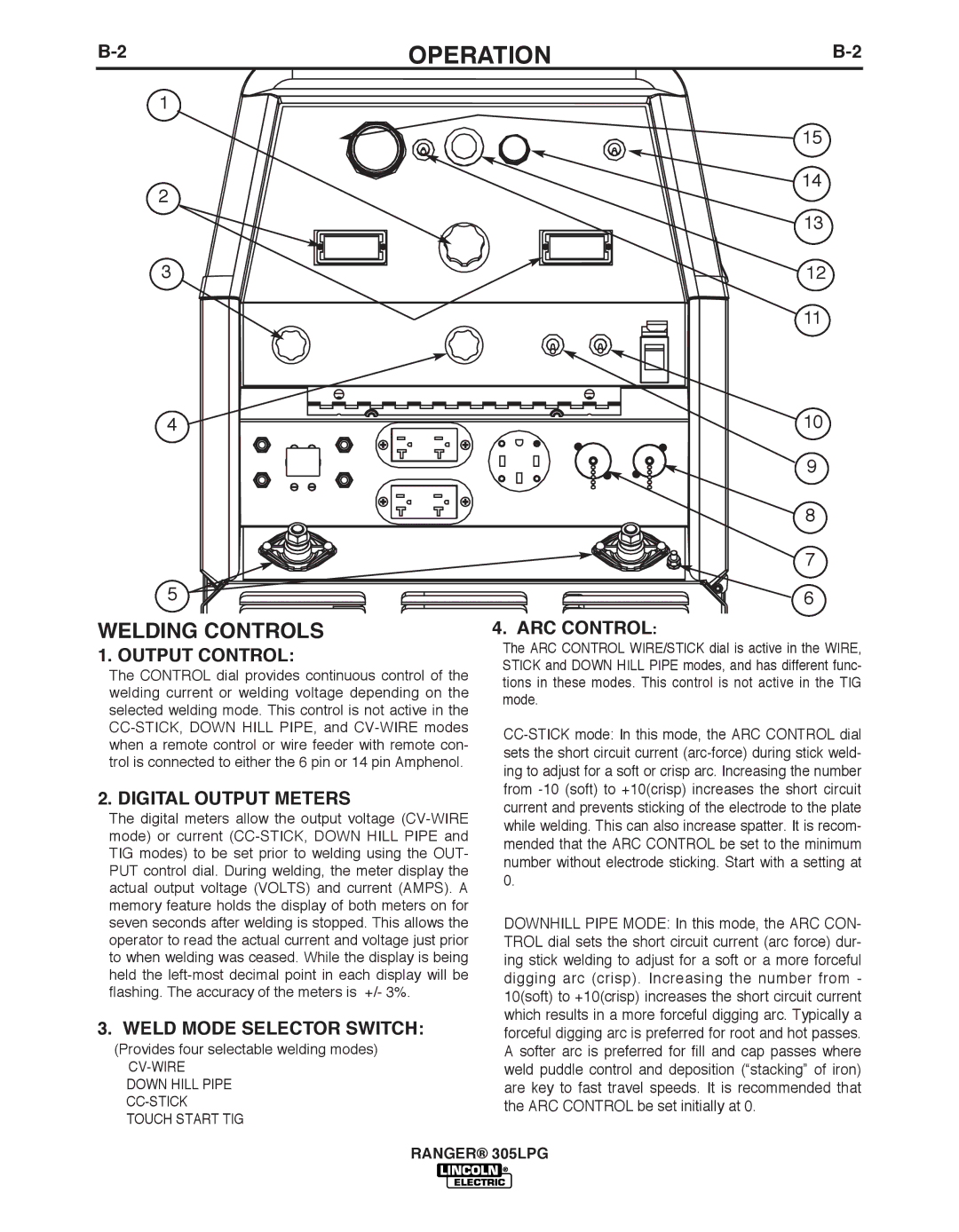

OPERATION |

1

2

3

4

5

WELDING CONTROLS

1. OUTPUT CONTROL:

The CONTROL dial provides continuous control of the welding current or welding voltage depending on the selected welding mode. This control is not active in the

2. DIGITAL OUTPUT METERS

The digital meters allow the output voltage

3. WELD MODE SELECTOR SWITCH:

(Provides four selectable welding modes)

![]() 15

15 ![]() 14

14

13

12

11

10

9

8

7

6

4. ARC CONTROL:

The ARC CONTROL WIRE/STICK dial is active in the WIRE, STICK and DOWN HILL PIPE modes, and has different func- tions in these modes. This control is not active in the TIG mode.

DOWNHILL PIPE MODE: In this mode, the ARC CON- TROL dial sets the short circuit current (arc force) dur- ing stick welding to adjust for a soft or a more forceful digging arc (crisp). Increasing the number from - 10(soft) to +10(crisp) increases the short circuit current which results in a more forceful digging arc. Typically a forceful digging arc is preferred for root and hot passes. A softer arc is preferred for fill and cap passes where weld puddle control and deposition (“stacking” of iron) are key to fast travel speeds. It is recommended that the ARC CONTROL be set initially at 0.

RANGER® 305LPG