LEARNING TO WELD |

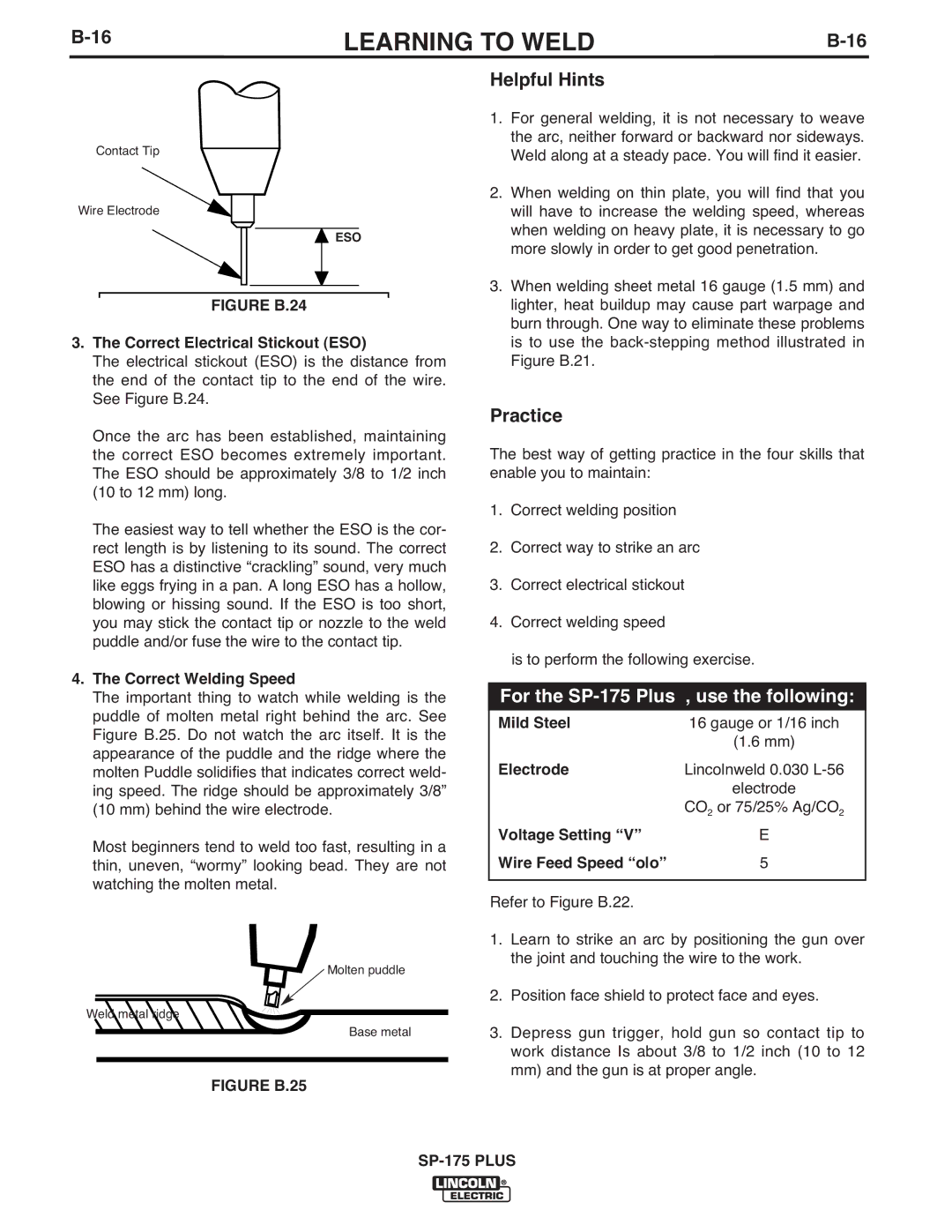

Contact Tip

Wire Electrode

![]() ESO

ESO

FIGURE B.24

3.The Correct Electrical Stickout (ESO)

The electrical stickout (ESO) is the distance from the end of the contact tip to the end of the wire. See Figure B.24.

Once the arc has been established, maintaining the correct ESO becomes extremely important. The ESO should be approximately 3/8 to 1/2 inch (10 to 12 mm) long.

The easiest way to tell whether the ESO is the cor- rect length is by listening to its sound. The correct ESO has a distinctive “crackling” sound, very much like eggs frying in a pan. A long ESO has a hollow, blowing or hissing sound. If the ESO is too short, you may stick the contact tip or nozzle to the weld puddle and/or fuse the wire to the contact tip.

4.The Correct Welding Speed

The important thing to watch while welding is the puddle of molten metal right behind the arc. See Figure B.25. Do not watch the arc itself. It is the appearance of the puddle and the ridge where the molten Puddle solidifies that indicates correct weld- ing speed. The ridge should be approximately 3/8” (10 mm) behind the wire electrode.

Most beginners tend to weld too fast, resulting in a thin, uneven, “wormy” looking bead. They are not watching the molten metal.

![]()

![]() Molten puddle

Molten puddle

Weld metal ridge

Base metal

FIGURE B.25

Helpful Hints

1.For general welding, it is not necessary to weave the arc, neither forward or backward nor sideways. Weld along at a steady pace. You will find it easier.

2.When welding on thin plate, you will find that you will have to increase the welding speed, whereas when welding on heavy plate, it is necessary to go more slowly in order to get good penetration.

3.When welding sheet metal 16 gauge (1.5 mm) and lighter, heat buildup may cause part warpage and burn through. One way to eliminate these problems is to use the

Practice

The best way of getting practice in the four skills that enable you to maintain:

1.Correct welding position

2.Correct way to strike an arc

3.Correct electrical stickout

4.Correct welding speed

is to perform the following exercise.

For the SP-175 Plus , use the following:

Mild Steel | 16 gauge or 1/16 inch |

| (1.6 mm) |

Electrode | Lincolnweld 0.030 |

| electrode |

| CO2 or 75/25% Ag/CO2 |

Voltage Setting “V” | E |

Wire Feed Speed “oo” | 5 |

|

|

Refer to Figure B.22. |

|

1.Learn to strike an arc by positioning the gun over the joint and touching the wire to the work.

2.Position face shield to protect face and eyes.

3.Depress gun trigger, hold gun so contact tip to work distance Is about 3/8 to 1/2 inch (10 to 12 mm) and the gun is at proper angle.