OPERATION | ||

|

|

|

•Hold the nozzle standoff 1/8” (3.2mm) to 3/16” (4.7mm) above the workpiece during cutting. Do not let the torch nozzle touch the work or carry a long arc.

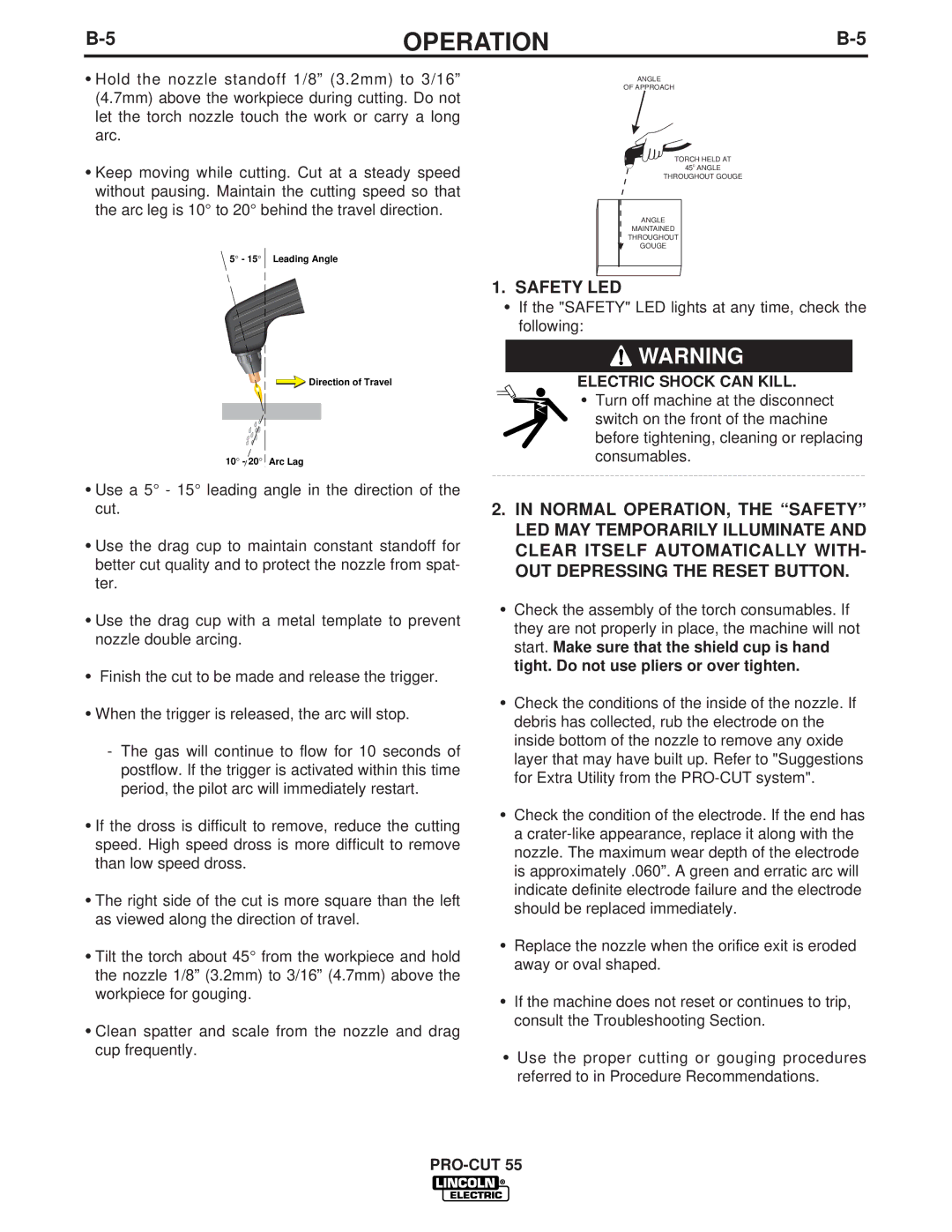

•Keep moving while cutting. Cut at a steady speed without pausing. Maintain the cutting speed so that the arc leg is 10° to 20° behind the travel direction.

5° - 15° Leading Angle

![]() Direction of Travel

Direction of Travel

10° - 20° Arc Lag

•Use a 5° - 15° leading angle in the direction of the cut.

•Use the drag cup to maintain constant standoff for better cut quality and to protect the nozzle from spat- ter.

•Use the drag cup with a metal template to prevent nozzle double arcing.

•Finish the cut to be made and release the trigger.

•When the trigger is released, the arc will stop.

-The gas will continue to flow for 10 seconds of postflow. If the trigger is activated within this time period, the pilot arc will immediately restart.

•If the dross is difficult to remove, reduce the cutting speed. High speed dross is more difficult to remove than low speed dross.

•The right side of the cut is more square than the left as viewed along the direction of travel.

•Tilt the torch about 45° from the workpiece and hold the nozzle 1/8” (3.2mm) to 3/16” (4.7mm) above the workpiece for gouging.

•Clean spatter and scale from the nozzle and drag cup frequently.

ANGLE

OF APPROACH

TORCH HELD AT

450 ANGLE

THROUGHOUT GOUGE

ANGLE

MAINTAINED

THROUGHOUT

GOUGE

1.SAFETY LED

•If the "SAFETY" LED lights at any time, check the following:

![]() WARNING

WARNING

ELECTRIC SHOCK CAN KILL.

• Turn off machine at the disconnect switch on the front of the machine before tightening, cleaning or replacing consumables.

2.IN NORMAL OPERATION, THE “SAFETY” LED MAY TEMPORARILY ILLUMINATE AND CLEAR ITSELF AUTOMATICALLY WITH- OUT DEPRESSING THE RESET BUTTON.

•Check the assembly of the torch consumables. If they are not properly in place, the machine will not start. Make sure that the shield cup is hand tight. Do not use pliers or over tighten.

•Check the conditions of the inside of the nozzle. If debris has collected, rub the electrode on the inside bottom of the nozzle to remove any oxide layer that may have built up. Refer to "Suggestions for Extra Utility from the

•Check the condition of the electrode. If the end has a

•Replace the nozzle when the orifice exit is eroded away or oval shaped.

•If the machine does not reset or continues to trip, consult the Troubleshooting Section.

•Use the proper cutting or gouging procedures referred to in Procedure Recommendations.