OPERATION | ||

|

|

|

CUTTING CAPABILITY

The

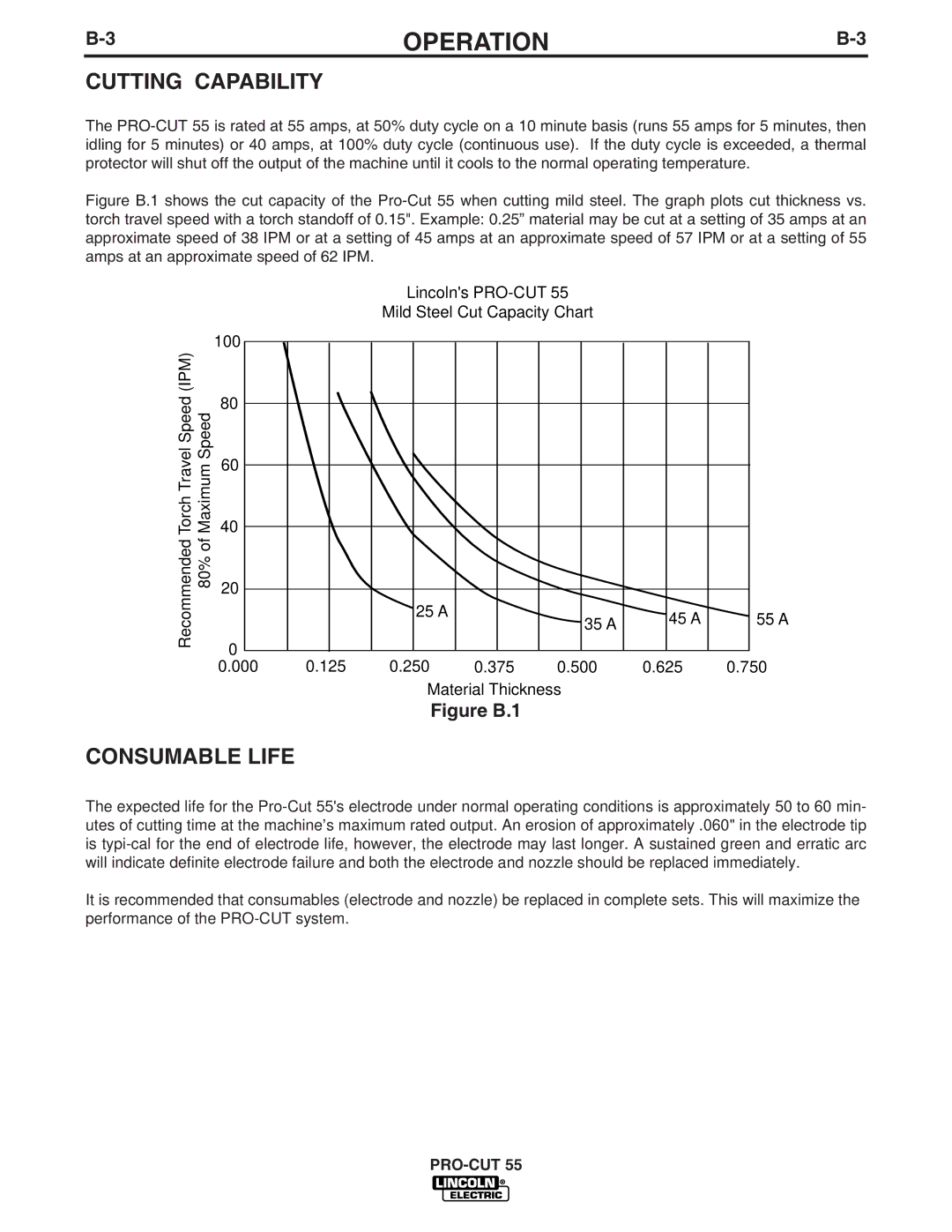

Figure B.1 shows the cut capacity of the Pro-Cut 55 when cutting mild steel. The graph plots cut thickness vs. torch travel speed with a torch standoff of 0.15". Example: 0.25” material may be cut at a setting of 35 amps at an approximate speed of 38 IPM or at a setting of 45 amps at an approximate speed of 57 IPM or at a setting of 55 amps at an approximate speed of 62 IPM.

Recommended Torch Travel Speed (IPM)

| 100 |

|

|

| |

Speed | 80 |

|

60 |

| |

Maximum |

| |

40 |

| |

80% of | 20 |

|

|

| |

| 0 |

|

|

| |

| 0.000 | |

Lincoln's

Mild Steel Cut Capacity Chart

|

|

| 25 A |

|

|

| 35 A |

| 45 A |

| 55 A |

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

0.125 | 0.250 | 0.375 | 0.500 | 0.625 | 0.750 | ||||||

Material Thickness

Figure B.1

CONSUMABLE LIFE

The expected life for the

It is recommended that consumables (electrode and nozzle) be replaced in complete sets. This will maximize the performance of the