INSTALLATION |

WARNING

BUILDUP OF SHIELDING GAS may harm health or kill.

•Shut off shielding gas supply

when not in use.

•SEE AMERICAN NATIONAL STANDARD

1.Chain the cylinder to a wall or other stationary sup- port to prevent the cylinder from falling over. Insulate the cylinder from the work circuit and earth ground.

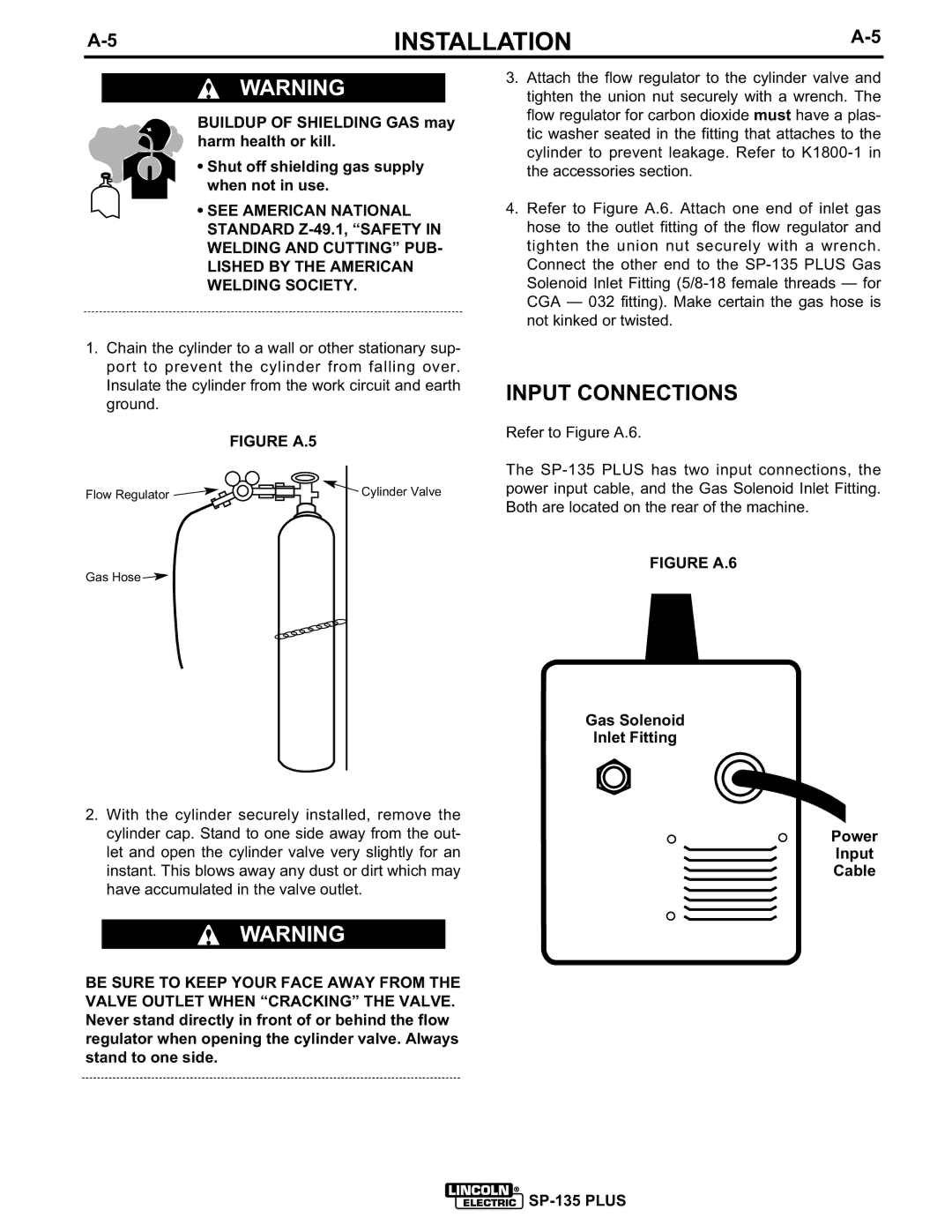

FIGURE A.5

Flow Regulator | Cylinder Valve |

Gas Hose![]()

3.Attach the flow regulator to the cylinder valve and tighten the union nut securely with a wrench. The flow regulator for carbon dioxide must have a plas- tic washer seated in the fitting that attaches to the cylinder to prevent leakage. Refer to

4.Refer to Figure A.6. Attach one end of inlet gas hose to the outlet fitting of the flow regulator and tighten the union nut securely with a wrench. Connect the other end to the

INPUT CONNECTIONS

Refer to Figure A.6.

The

FIGURE A.6

Gas Solenoid

Inlet Fitting

2. With the cylinder securely installed, remove the |

|

cylinder cap. Stand to one side away from the out- | Power |

let and open the cylinder valve very slightly for an | Input |

instant. This blows away any dust or dirt which may | Cable |

have accumulated in the valve outlet. |

|

WARNING

BE SURE TO KEEP YOUR FACE AWAY FROM THE VALVE OUTLET WHEN “CRACKING” THE VALVE. Never stand directly in front of or behind the flow regulator when opening the cylinder valve. Always stand to one side.