OPERATION | ||

|

|

|

4-Step Sequence

Note:

1.Press and hold the Arc Start Switch to start the sequence. The machine will open the gas valve to start the flow of the shielding gas. After 0.5 second preflow time to purge air from the torch hose, the out- put of the machine is turned ON. At this time the arc can be started. After the arc is started the output cur- rent will be at the Start/Finish current. This condition can be maintained as long or as short as necessary.

If the Start/Finish current is not necessary, do not hold the TIG torch trigger as described at the beginning of this step. Instead, quickly press and release the trig- ger. In this condition, the machine will automatically pass from Step 1 to Step 2 when the arc is started.

2.Release the TIG torch trigger to start the main part of the weld.

The output current will increase to the welding current. The time for this increase or upslope is presettable. The default is 0.5 seconds.

3.Press and hold the TIG torch trigger when the main part of the weld is complete.

The machine will now decrease the output current at a controlled rate or downslope time, until the Start/Finish current is reached. The downslope time is adjusted by the Downslope Parameter. This Start/Finish current can be maintained as long or as short as necessary.

4.Release the TIG torch trigger.

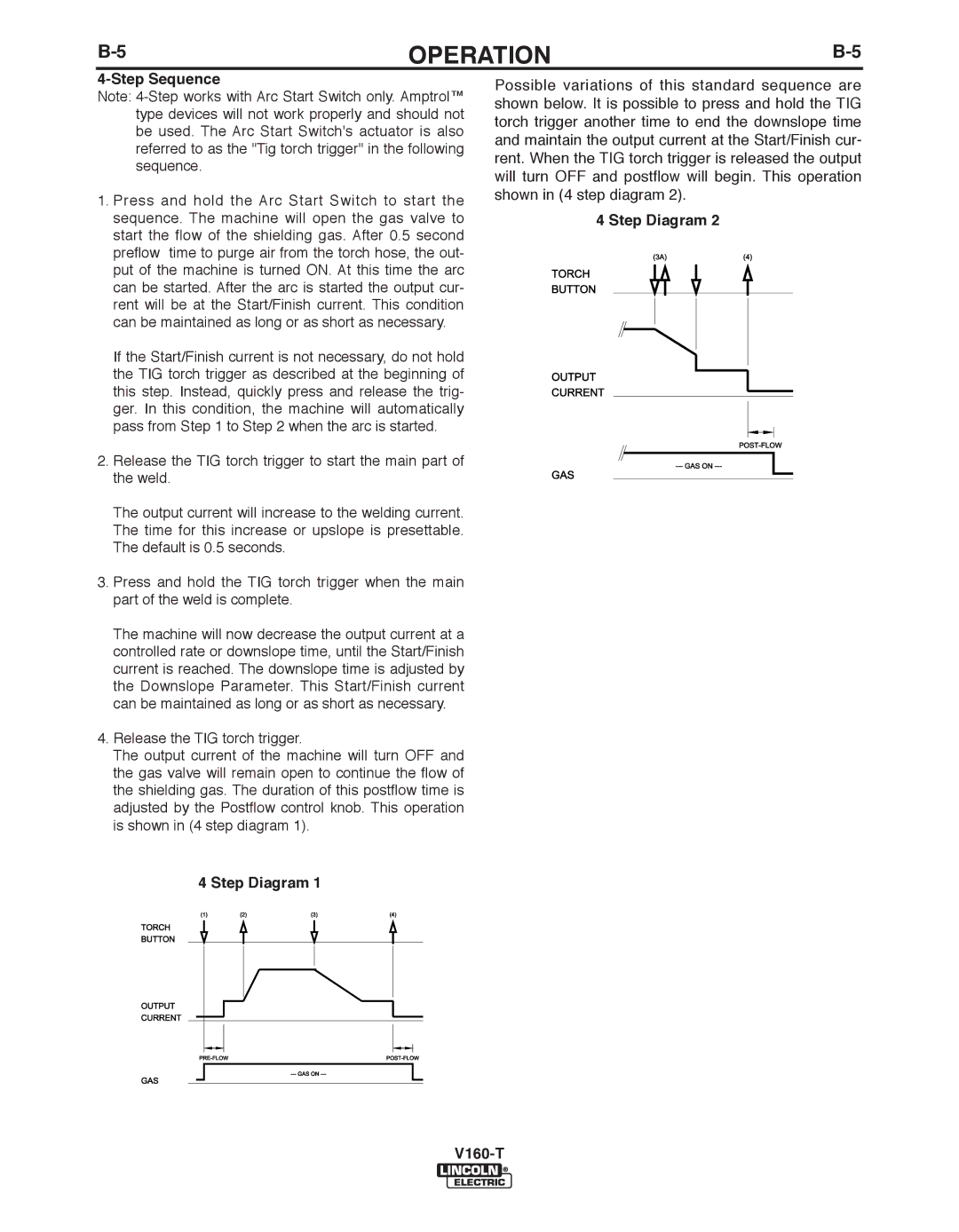

The output current of the machine will turn OFF and the gas valve will remain open to continue the flow of the shielding gas. The duration of this postflow time is adjusted by the Postflow control knob. This operation is shown in (4 step diagram 1).

4 Step Diagram 1

Possible variations of this standard sequence are shown below. It is possible to press and hold the TIG torch trigger another time to end the downslope time and maintain the output current at the Start/Finish cur- rent. When the TIG torch trigger is released the output will turn OFF and postflow will begin. This operation shown in (4 step diagram 2).