TROUbLESHOOTING | ||

|

|

|

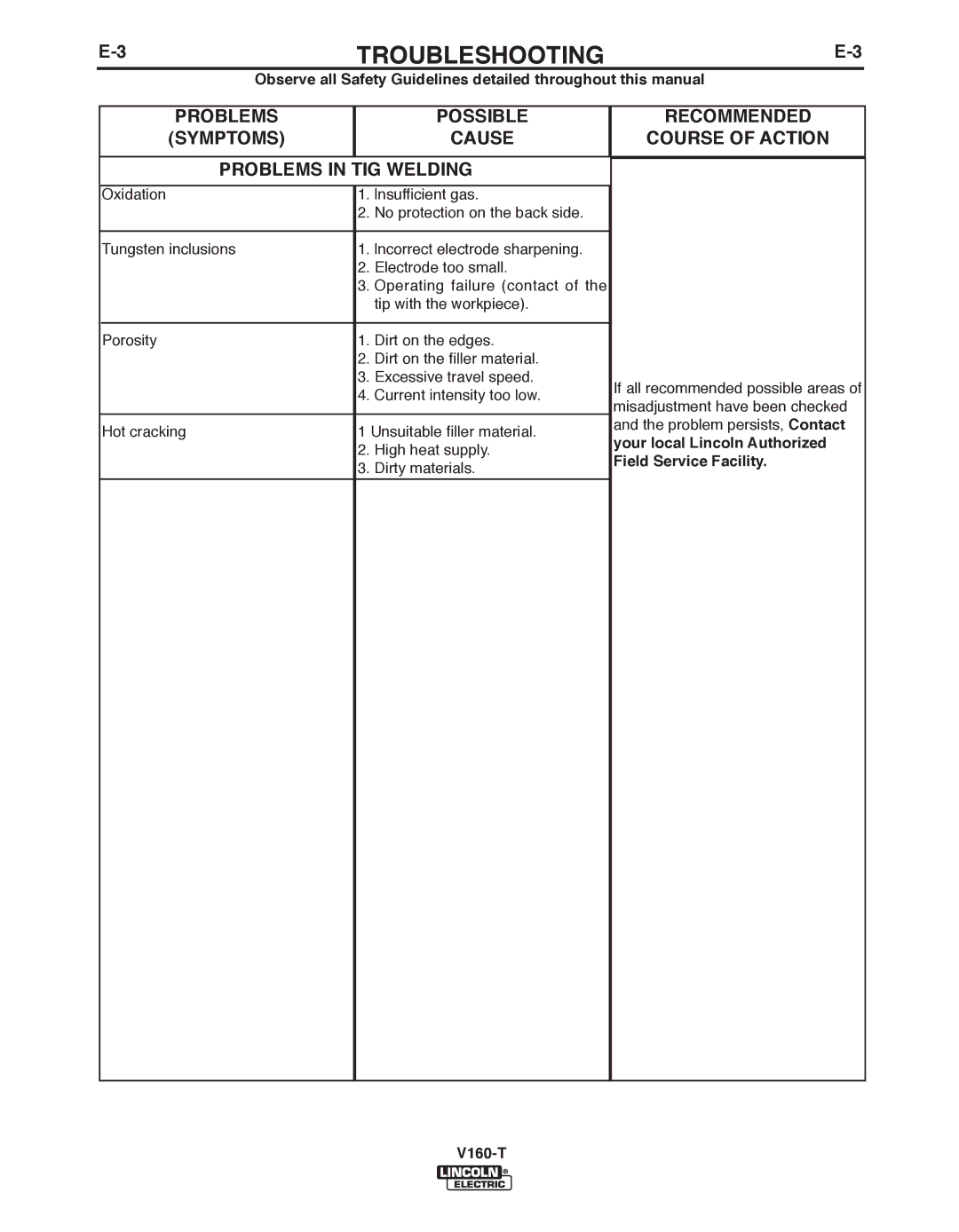

| Observe all Safety Guidelines detailed throughout this manual |

|

|

|

|

PRObLEMS

(SYMPTOMS)

POSSIbLE

CAUSE

RECOMMENDED

COURSE OF ACTION

PRObLEMS IN TIG WELDING

Oxidation | 1. lnsufficient gas. |

| |

| 2. | No protection on the back side. |

|

|

|

| |

Tungsten inclusions | 1. lncorrect electrode sharpening. |

| |

| 2. | Electrode too small. |

|

| 3. | Operating failure (contact of the |

|

|

| tip with the workpiece). |

|

|

|

| |

Porosity | 1. Dirt on the edges. |

| |

| 2. | Dirt on the filler material. |

|

| 3. | Excessive travel speed. |

|

| 4. | Current intensity too low. |

|

|

|

| |

Hot cracking | 1 Unsuitable filler material. |

| |

| 2. | High heat supply. |

|

| 3. | Dirty materials. |

|

|

|

|

|

If all recommended possible areas of misadjustment have been checked and the problem persists, Contact your local Lincoln Authorized Field Service Facility.