OPERATION | ||

|

|

|

When the mode switch is in the Lift TIG position, the stick welding functions are disabled and the machine is ready for Lift TIG welding. Lift TIG is a method of start- ing a TIG weld by first pressing the TIG torch electrode on the work piece in order to create a low current short circuit. Then, the electrode is lifted from the work piece to start the TIG arc. After machine output is triggered ON, with an Arc Start Switch or Foot Amptrol the arc must be started within 6.5 seconds or output will turn OFF and trigger sequence must be restarted.

When the mode switch is in the HF TIG position, the stick welding functions are disabled and the machine is ready for HF TIG welding. During the HF TIG mode, the TIG arc is started by HF without pressing the electrode on the work piece. After triggering output ON, the HF (and out- put) used for starting the TIG arc will remain ON for 6.5 seconds. If the arc is not started in this time limit, the trig- ger sequence must be restarted.

5.Trigger Mode Switch: This switch changes between 2- step and

6.Power LED: This indicator will blink on and off when the machine is first turned on. After approximately 2 seconds it will stop blinking and remain on to signal that the machine is ready. The indicator will also blink during over current conditions when operating on 115V input.

7.Thermal LED: This indicator will turn on when the machine is overheated and the output has been disabled. This normally occurs when the duty cycle of the machine

has been exceeded.

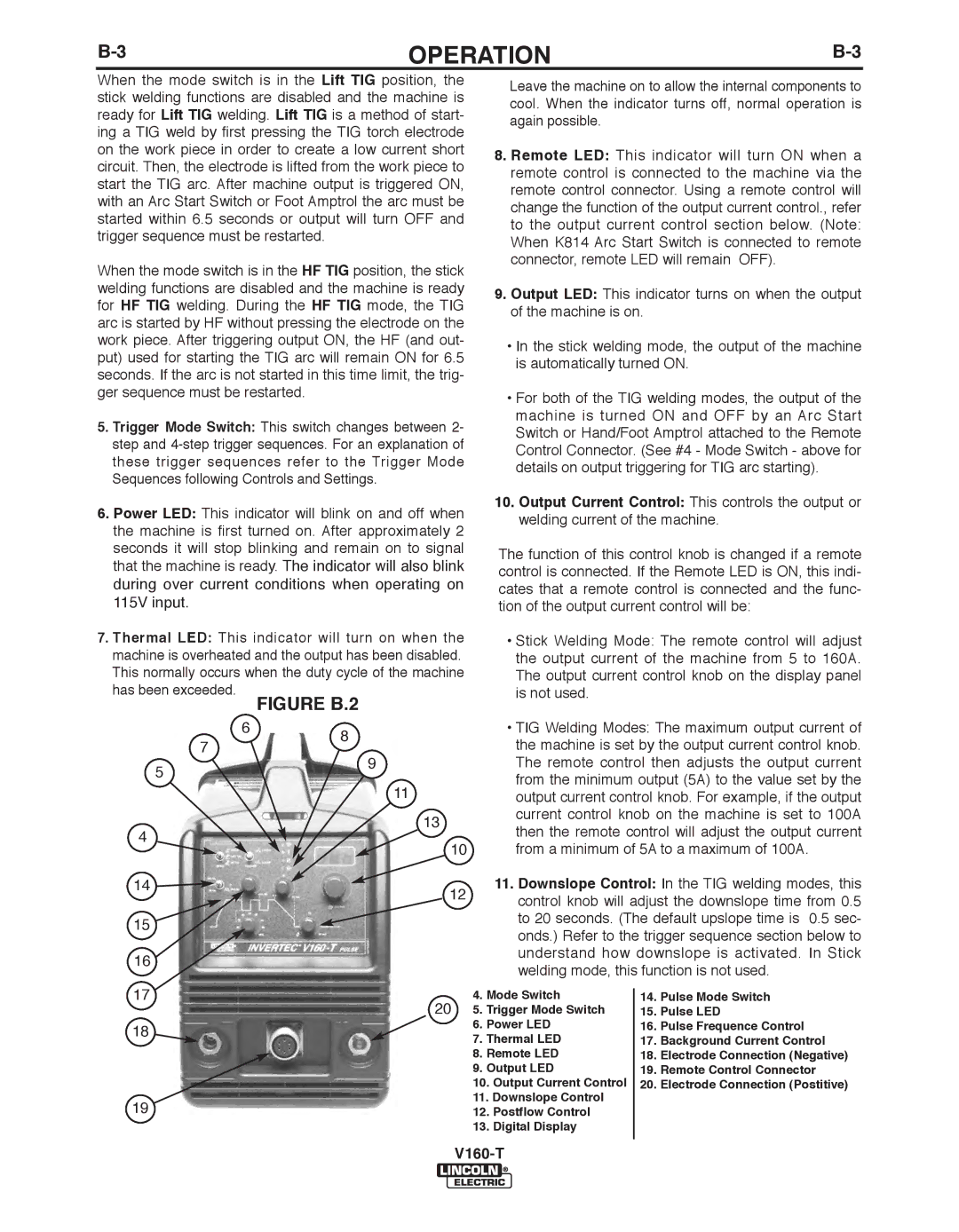

FIGURE b.2

Leave the machine on to allow the internal components to cool. When the indicator turns off, normal operation is again possible.

8.Remote LED: This indicator will turn ON when a remote control is connected to the machine via the remote control connector. Using a remote control will change the function of the output current control., refer to the output current control section below. (Note: When K814 Arc Start Switch is connected to remote connector, remote LED will remain OFF).

9.Output LED: This indicator turns on when the output of the machine is on.

•In the stick welding mode, the output of the machine is automatically turned ON.

•For both of the TIG welding modes, the output of the machine is turned ON and OFF by an Arc Start Switch or Hand/Foot Amptrol attached to the Remote Control Connector. (See #4 - Mode Switch - above for details on output triggering for TIG arc starting).

10.Output Current Control: This controls the output or welding current of the machine.

The function of this control knob is changed if a remote control is connected. If the Remote LED is ON, this indi- cates that a remote control is connected and the func- tion of the output current control will be:

•Stick Welding Mode: The remote control will adjust the output current of the machine from 5 to 160A. The output current control knob on the display panel is not used.

|

| 6 | 8 | • TIG Welding Modes: The maximum output current of | ||

|

| 7 | the machine is set by the output current control knob. | |||

|

|

| ||||

| 5 |

| 9 | The remote control then adjusts the output current | ||

|

|

| from the minimum output (5A) to the value set by the | |||

|

|

| 11 | |||

|

|

| output current control knob. For example, if the output | |||

|

|

|

| |||

|

|

| 13 | current control knob on the machine is set to 100A | ||

4 |

|

| then the remote control will adjust the output current | |||

|

|

| ||||

|

| 10 | from a minimum of 5A to a maximum of 100A. | |||

|

|

| ||||

14 |

|

| 12 | 11. Downslope Control: In the TIG welding modes, this | ||

|

|

| control knob will adjust the downslope time from 0.5 | |||

|

|

|

| |||

15 |

|

|

| to 20 seconds. (The default upslope time is 0.5 sec- | ||

|

|

| onds.) Refer to the trigger sequence section below to | |||

|

|

|

| |||

16 |

|

|

| understand how downslope is activated. In Stick | ||

|

|

| welding mode, this function is not used. | |||

|

|

|

| |||

17 |

|

| 20 | 4. Mode Switch |

| 14. Pulse Mode Switch |

|

|

| ||||

|

|

| 5. Trigger Mode Switch |

| 15. Pulse LED | |

18 |

|

|

| 6. Power LED |

| 16. Pulse Frequence Control |

|

|

| 7. Thermal LED |

| 17. background Current Control | |

|

|

|

|

| ||

|

|

|

| 8. Remote LED |

| 18. Electrode Connection (Negative) |

|

|

|

| 9. Output LED |

| 19. Remote Control Connector |

|

|

|

| 10. Output Current Control |

| 20. Electrode Connection (Postitive) |

19 |

|

|

| 11. Downslope Control |

|

|

|

|

| 12. Postflow Control |

|

| |

|

|

|

| 13. Digital Display |

|

|

|

|

|

|

|

|

|