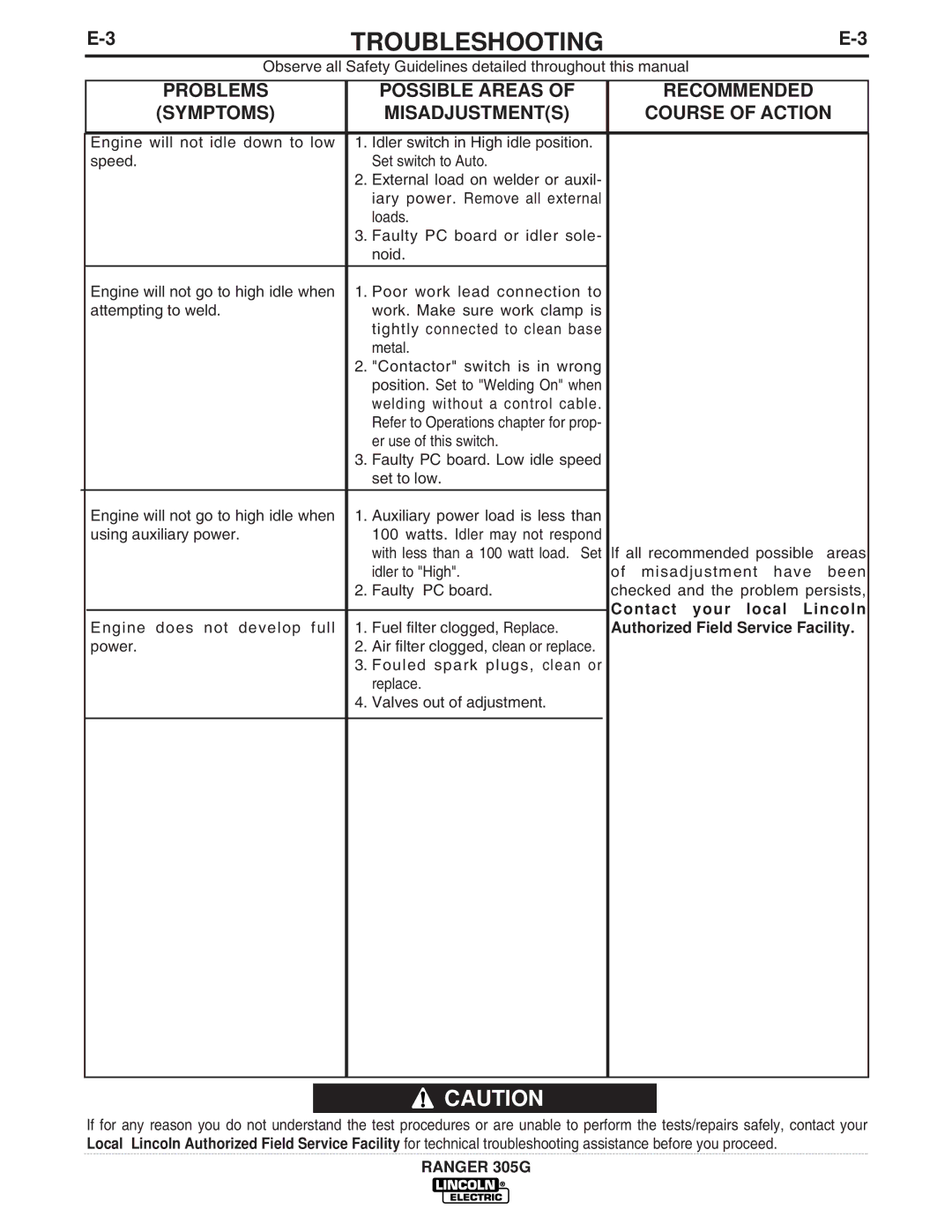

TROUBLESHOOTING | ||

|

|

|

| Observe all Safety Guidelines detailed throughout this manual |

|

|

|

|

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

| Engine will not idle down to low | 1. Idler switch in High idle position. | ||

| speed. |

| Set switch to Auto. | |

|

| 2. | External load on welder or auxil- | |

|

|

| iary power. Remove all external | |

|

|

| loads. | |

|

| 3. | Faulty PC board or idler sole- | |

|

|

| noid. | |

|

|

|

| |

| Engine will not go to high idle when | 1. Poor work lead connection to | ||

| attempting to weld. |

| work. Make sure work clamp is | |

|

|

| tightly connected to clean base | |

|

|

| metal. | |

|

| 2. | "Contactor" switch is in wrong | |

|

|

| position. Set to "Welding On" when | |

|

|

| welding without a control cable. | |

|

|

| Refer to Operations chapter for prop- | |

|

|

| er use of this switch. | |

|

| 3. | Faulty PC board. Low idle speed | |

|

|

| set to low. | |

|

|

|

| |

| Engine will not go to high idle when | 1. Auxiliary power load is less than | ||

| using auxiliary power. |

| 100 watts. Idler may not respond | |

|

|

| with less than a 100 watt load. Set | |

|

|

| idler to "High". | |

|

| 2. | Faulty PC board. | |

|

|

|

| |

| Engine does not develop full | 1. Fuel filter clogged, Replace. | ||

| power. | 2. Air filter clogged, clean or replace. | ||

|

| 3. | Fouled spark plugs, clean or | |

|

|

| replace. | |

|

| 4. | Valves out of adjustment. | |

|

|

|

|

|

|

|

|

|

|

If all recommended possible areas of misadjustment have been checked and the problem persists,

Contact your local Lincoln Authorized Field Service Facility.

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.