OPERATION | ||

|

|

|

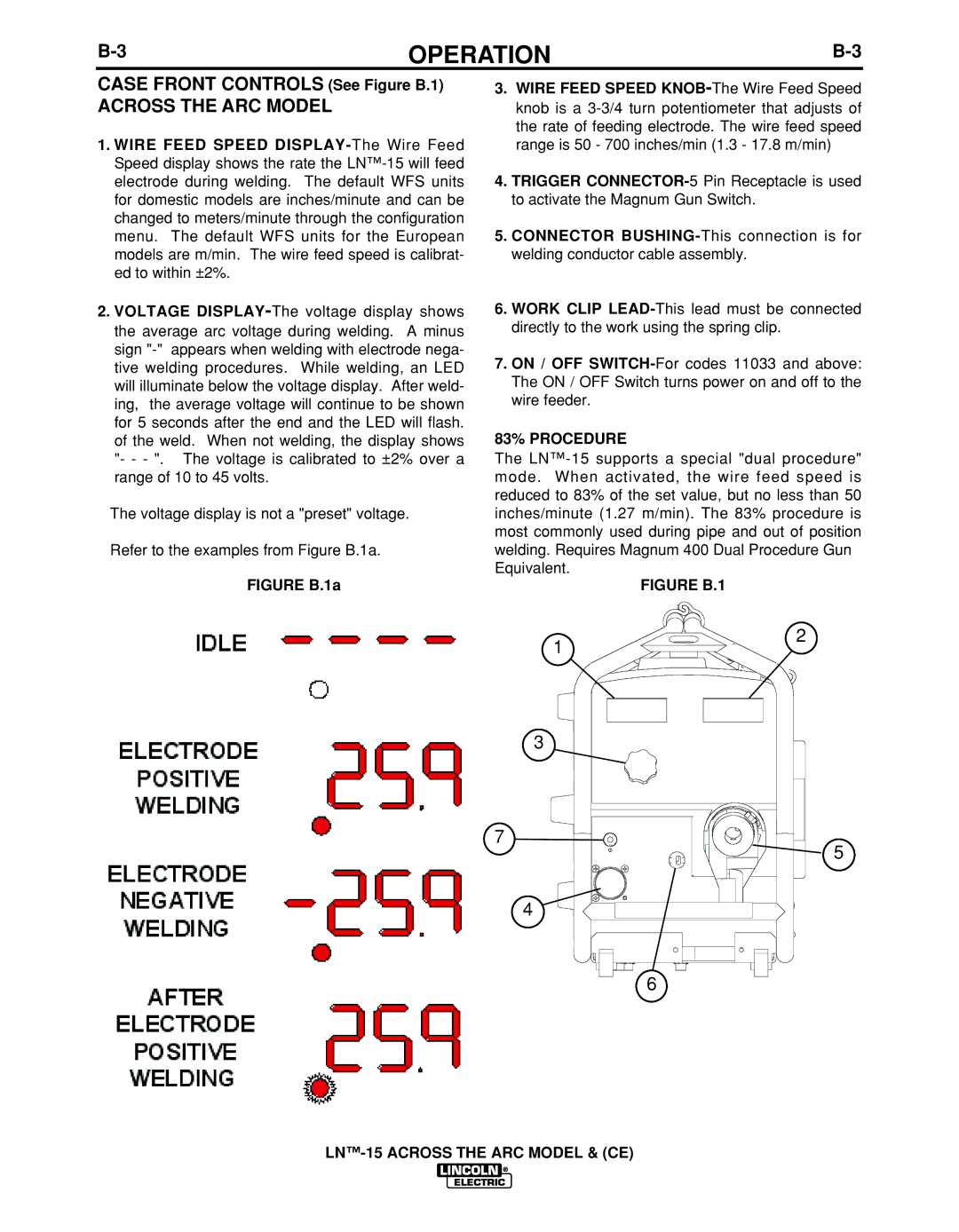

CASE FRONT CONTROLS (See Figure B.1)

ACROSS THE ARC MODEL

1.WIRE FEED SPEED

2.VOLTAGE

The voltage display is not a "preset" voltage.

Refer to the examples from Figure B.1a.

FIGURE B.1a

3.WIRE FEED SPEED KNOB-The Wire Feed Speed knob is a 3-3/4 turn potentiometer that adjusts of the rate of feeding electrode. The wire feed speed range is 50 - 700 inches/min (1.3 - 17.8 m/min)

4.TRIGGER

5.CONNECTOR

6.WORK CLIP

7.ON / OFF

83% PROCEDURE

The

FIGURE B.1

1

3

2

7 ![]()

![]()

![]()

![]()

![]()

4

5

6