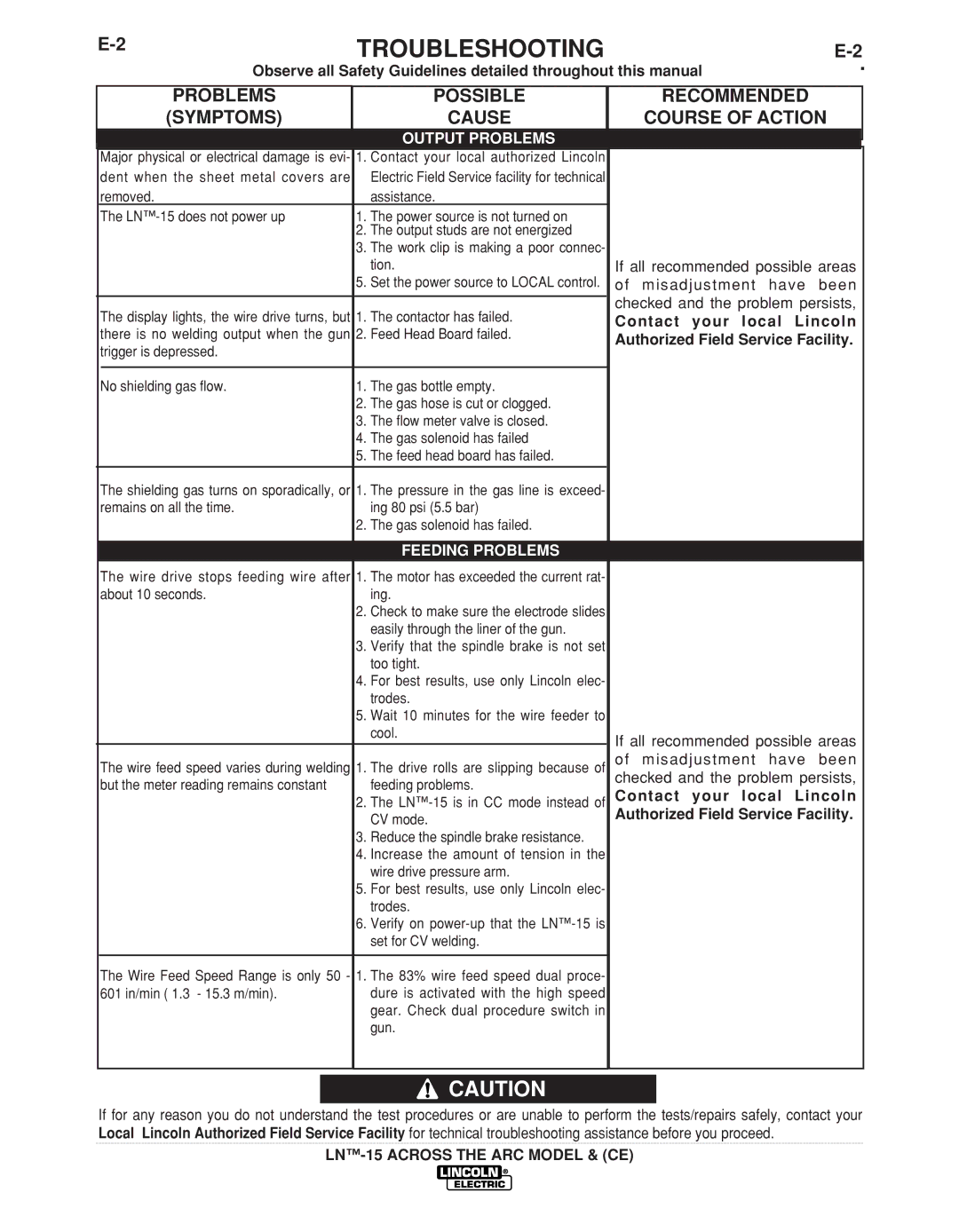

| TROUBLESHOOTING | ||||

| Observe all Safety Guidelines detailed throughout this manual |

| |||

|

|

|

|

|

|

| PROBLEMS |

| POSSIBLE | RECOMMENDED |

|

| (SYMPTOMS) |

| CAUSE | COURSE OF ACTION |

|

|

|

| OUTPUT PROBLEMS |

|

|

|

|

|

|

| |

| Major physical or electrical damage is evi- | 1. | Contact your local authorized Lincoln |

|

|

| dent when the sheet metal covers are |

| Electric Field Service facility for technical |

|

|

| removed. |

| assistance. |

|

|

| The | 1. | The power source is not turned on |

|

|

|

| 2. | The output studs are not energized |

|

|

|

| 3. | The work clip is making a poor connec- |

|

|

|

|

| tion. | If all recommended possible areas | |

|

| 5. | Set the power source to LOCAL control. | of misadjustment have been | |

|

|

|

| checked and the problem persists, | |

| The display lights, the wire drive turns, but | 1. | The contactor has failed. | ||

| Contact your local Lincoln | ||||

| there is no welding output when the gun | 2. | Feed Head Board failed. | ||

| Authorized Field Service Facility. | ||||

| trigger is depressed. |

|

| ||

|

|

|

|

| |

|

|

|

|

|

|

| No shielding gas flow. | 1. | The gas bottle empty. |

|

|

|

| 2. | The gas hose is cut or clogged. |

|

|

|

| 3. | The flow meter valve is closed. |

|

|

|

| 4. | The gas solenoid has failed |

|

|

|

| 5. | The feed head board has failed. |

|

|

|

|

|

|

|

|

| The shielding gas turns on sporadically, or | 1. | The pressure in the gas line is exceed- |

|

|

| remains on all the time. |

| ing 80 psi (5.5 bar) |

|

|

|

| 2. | The gas solenoid has failed. |

|

|

|

|

|

|

|

|

|

|

| FEEDING PROBLEMS |

|

|

The wire drive stops feeding wire after 1. The motor has exceeded the current rat-

about 10 seconds.ing.

2. Check to make sure the electrode slides easily through the liner of the gun.

3. Verify that the spindle brake is not set too tight.

4. For best results, use only Lincoln elec- trodes.

5. Wait 10 minutes for the wire feeder to cool.

The wire feed speed varies during welding 1. The drive rolls are slipping because of

but the meter reading remains constant feeding problems.

2. The

3. Reduce the spindle brake resistance.

4. Increase the amount of tension in the wire drive pressure arm.

5. For best results, use only Lincoln elec- trodes.

6. Verify on

The Wire Feed Speed Range is only 50 - 1. The 83% wire feed speed dual proce-

601 in/min ( 1.3 - 15.3 m/min).dure is activated with the high speed gear. Check dual procedure switch in gun.

If all recommended possible areas of misadjustment have been checked and the problem persists,

Contact your local Lincoln Authorized Field Service Facility.

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.