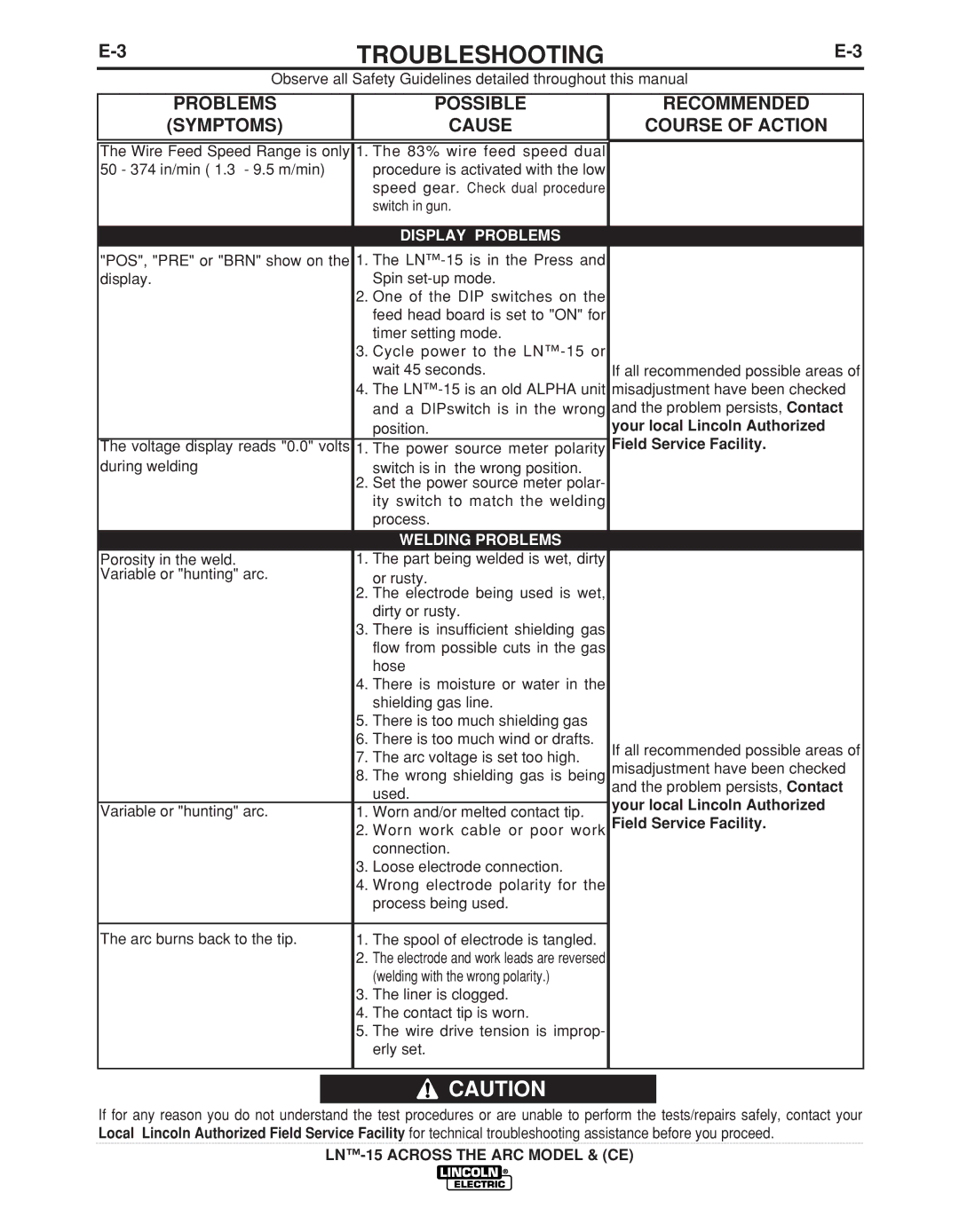

TROUBLESHOOTING | ||

|

|

|

| Observe all Safety Guidelines detailed throughout this manual |

|

|

|

|

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

The Wire Feed Speed Range is only | 1. The 83% wire feed speed dual |

| |

50 - 374 in/min ( 1.3 - 9.5 m/min) |

| procedure is activated with the low |

|

|

| speed gear. Check dual procedure |

|

|

| switch in gun. |

|

|

|

|

|

|

| DISPLAY PROBLEMS |

|

"POS", "PRE" or "BRN" show on the | 1. | The |

|

display. |

| Spin |

|

| 2. | One of the DIP switches on the |

|

|

| feed head board is set to "ON" for |

|

|

| timer setting mode. |

|

| 3. Cycle power to the |

| |

|

| wait 45 seconds. | If all recommended possible areas of |

| 4. | The | misadjustment have been checked |

|

| and a DIPswitch is in the wrong | and the problem persists, Contact |

|

| position. | your local Lincoln Authorized |

|

|

| Field Service Facility. |

The voltage display reads "0.0" volts | 1. | The power source meter polarity | |

during welding |

| switch is in the wrong position. |

|

| 2. | Set the power source meter polar- |

|

|

| ity switch to match the welding |

|

|

| process. |

|

|

|

|

|

|

| WELDING PROBLEMS |

|

Porosity in the weld. | 1. | The part being welded is wet, dirty |

|

Variable or "hunting" arc. |

| or rusty. |

|

| 2. | The electrode being used is wet, |

|

|

| dirty or rusty. |

|

| 3. | There is insufficient shielding gas |

|

|

| flow from possible cuts in the gas |

|

|

| hose |

|

| 4. | There is moisture or water in the |

|

|

| shielding gas line. |

|

| 5. | There is too much shielding gas |

|

| 6. | There is too much wind or drafts. | If all recommended possible areas of |

| 7. | The arc voltage is set too high. | |

| misadjustment have been checked | ||

| 8. | The wrong shielding gas is being | |

|

| used. | and the problem persists, Contact |

|

| your local Lincoln Authorized | |

Variable or "hunting" arc. | 1. | Worn and/or melted contact tip. | |

| 2. Worn work cable or poor work | Field Service Facility. | |

|

| connection. |

|

| 3. | Loose electrode connection. |

|

| 4. | Wrong electrode polarity for the |

|

|

| process being used. |

|

|

|

|

|

The arc burns back to the tip. | 1. | The spool of electrode is tangled. |

|

| 2. | The electrode and work leads are reversed |

|

|

| (welding with the wrong polarity.) |

|

| 3. | The liner is clogged. |

|

| 4. | The contact tip is worn. |

|

| 5. | The wire drive tension is improp- |

|

|

| erly set. |

|

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.