OPERATION |

ENGINE OPERATION

Starting/Shutdown Instructions

Be sure all

Remove all loads connected to the AC power recepta- cles. Before starting, first open the fuel shutoff valve.

Always pull the choke control out when starting the engine; cold, warm or hot.

Turn the engine switch to the “Start”![]() position and crank the engine until it starts, slowly return the choke control to the full “in” position (choke open), and turn

position and crank the engine until it starts, slowly return the choke control to the full “in” position (choke open), and turn

the switch to the Auto Idle ( ![]() /

/![]() ) position. Do not turn the switch to the “start” position while the engine is running because this will cause damage to the ring gear and/or starter motor.

) position. Do not turn the switch to the “start” position while the engine is running because this will cause damage to the ring gear and/or starter motor.

Stopping the Engine

Remove all welding and auxiliary power loads and allow engine to run for a few minutes to cool the engine.

Stop the engine by placing the engine switch in the

“Off” ( ![]() ) position.

) position.

![]() WARNING

WARNING

Close the fuel valve when the machine is transported to prevent fuel leakage from the carburetor.

Break-in Period

It is normal for any engine to use larger quantities of oil until

![]() CAUTION

CAUTION

IN ORDER TO ACCOMPLISH THIS

Low Oil Sensing

This engine has a built in sensor which responds to low oil level (not pressure). When activated, the sys- tem will shut the engine down. The engine will not restart until sufficient oil is added. Check oil level fre- quently and add oil as required to the full mark on the dipstick. DO NOT OVERFILL.

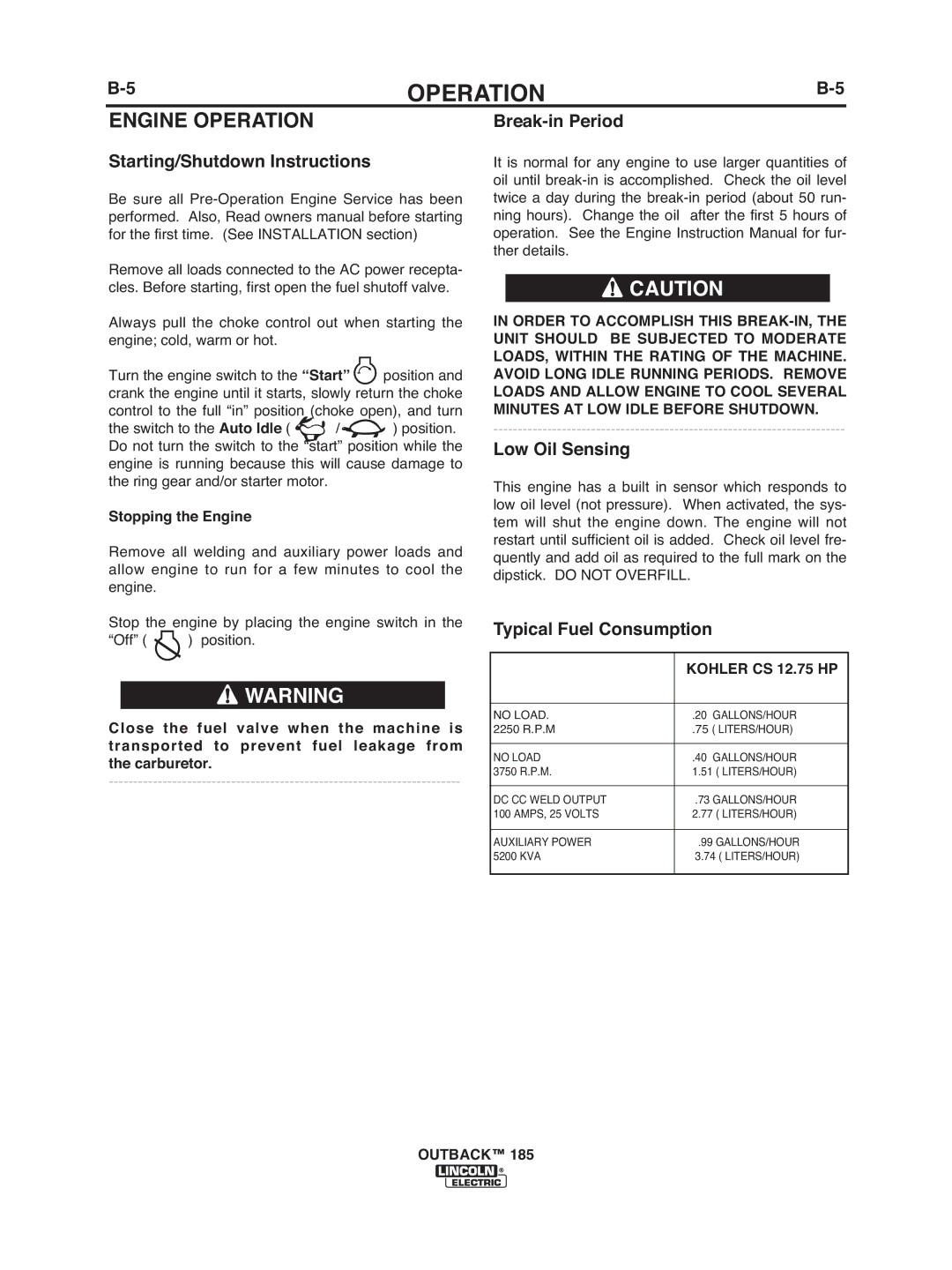

Typical Fuel Consumption

| KOHLER CS 12.75 HP |

|

|

NO LOAD. | .20 GALLONS/HOUR |

2250 R.P.M | .75 ( LITERS/HOUR) |

|

|

NO LOAD | .40 GALLONS/HOUR |

3750 R.P.M. | 1.51 ( LITERS/HOUR) |

|

|

DC CC WELD OUTPUT | .73 GALLONS/HOUR |

100 AMPS, 25 VOLTS | 2.77 ( LITERS/HOUR) |

|

|

AUXILIARY POWER | .99 GALLONS/HOUR |

5200 KVA | 3.74 ( LITERS/HOUR) |

|

|

OUTBACK™ 185

![]() ®

®