OPERATION | ||

|

|

|

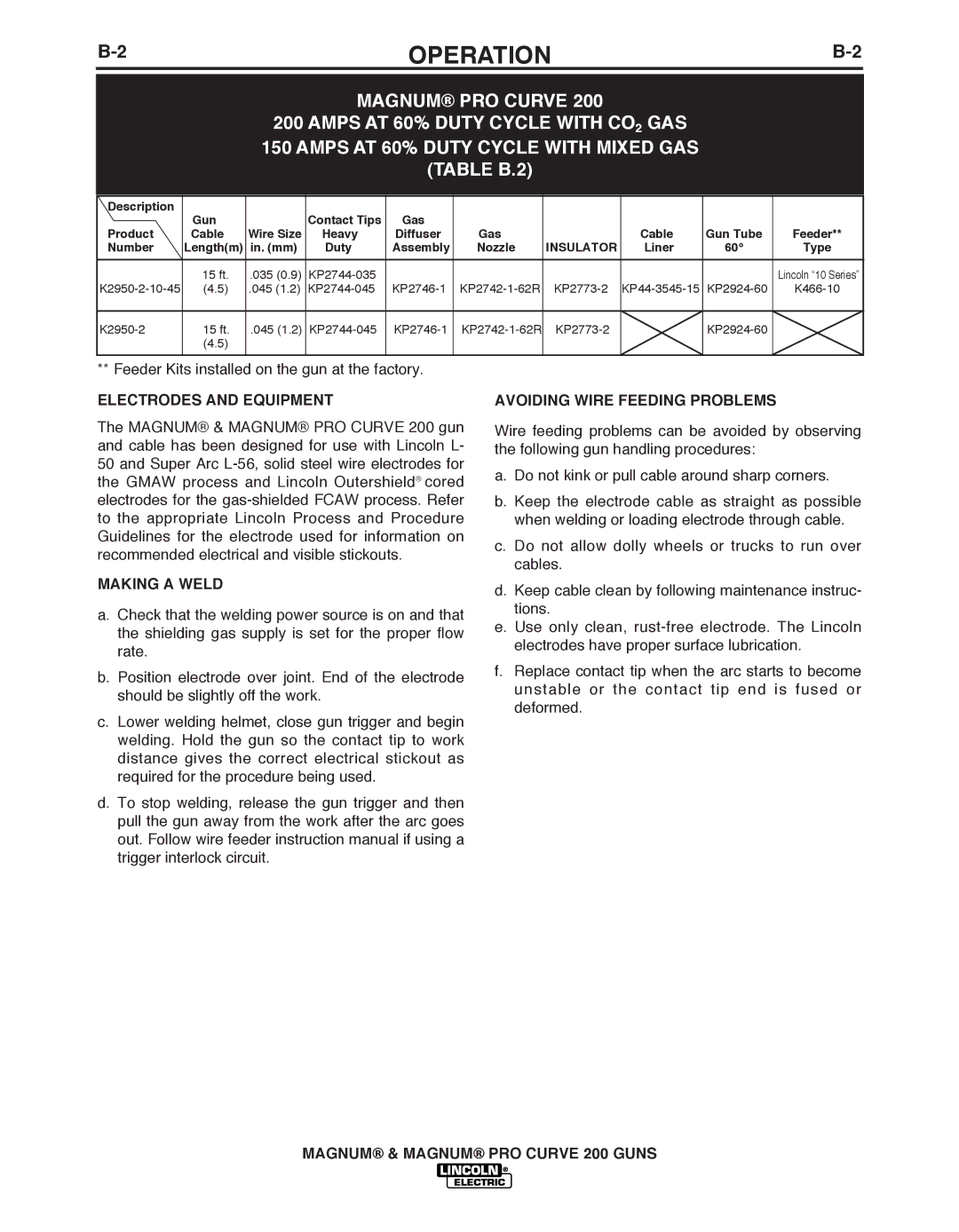

MAGNUM® PRO CURVE 200

200 AMPS AT 60% DUTY CYCLE WITH CO2 GAS 150 AMPS AT 60% DUTY CYCLE WITH MIXED GAS (TAbLE b.2)

Description | Gun |

| Contact Tips | Gas |

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

| |||

Product | Cable | Wire Size | Heavy | Diffuser | Gas |

| Cable | Gun Tube | Feeder** | ||

Number | Length(m) | in. (mm) | Duty | Assembly | Nozzle | INSULATOR | Liner | 60° | Type | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 15 ft. | .035 (0.9) |

|

|

|

|

| Lincoln “10 Series” | |

(4.5) | .045 (1.2) | ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

15 ft. | .045 (1.2) |

|

| ||||||||

|

|

| (4.5) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

** Feeder Kits installed on the gun at the factory.

ELECTRODES AND EQUIPMENT

The MAGNUM® & MAGNUM® PRO CURVE 200 gun and cable has been designed for use with Lincoln L- 50 and Super Arc

MAKING A WELD

a.Check that the welding power source is on and that the shielding gas supply is set for the proper flow rate.

b.Position electrode over joint. End of the electrode should be slightly off the work.

c.Lower welding helmet, close gun trigger and begin welding. Hold the gun so the contact tip to work distance gives the correct electrical stickout as required for the procedure being used.

d.To stop welding, release the gun trigger and then pull the gun away from the work after the arc goes out. Follow wire feeder instruction manual if using a trigger interlock circuit.

AVOIDING WIRE FEEDING PRObLEMS

Wire feeding problems can be avoided by observing the following gun handling procedures:

a.Do not kink or pull cable around sharp corners.

b.Keep the electrode cable as straight as possible when welding or loading electrode through cable.

c.Do not allow dolly wheels or trucks to run over cables.

d.Keep cable clean by following maintenance instruc- tions.

e.Use only clean,

f.Replace contact tip when the arc starts to become unstable or the contact tip end is fused or deformed.

MAGNUM® & MAGNUM® PRO CURVE 200 GUNS