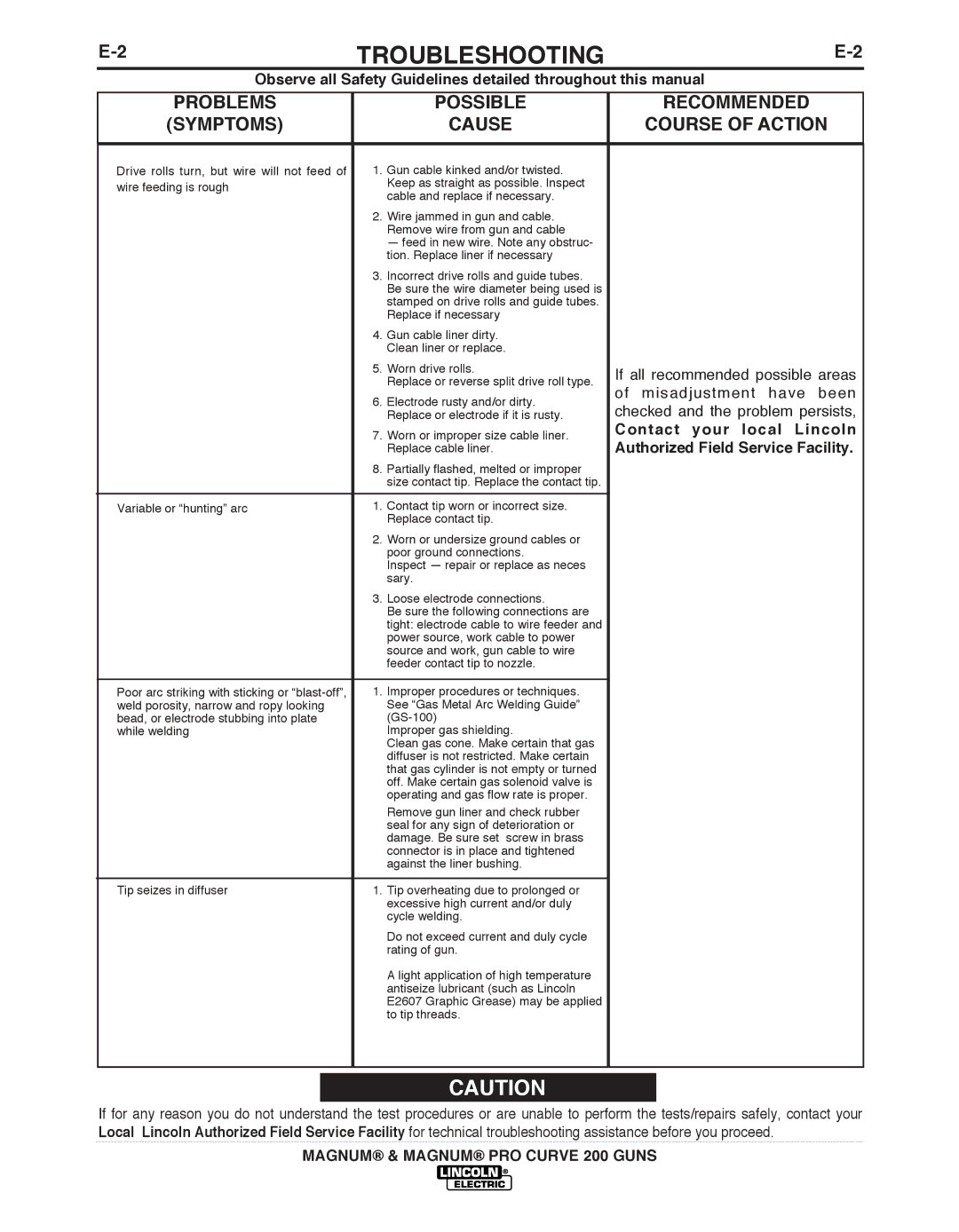

TROUbLESHOOTING | ||

|

|

|

| Observe all Safety Guidelines detailed throughout this manual |

|

|

|

|

PRObLEMS

(SYMPTOMS)

POSSIbLE

CAUSE

RECOMMENDED

COURSE OF ACTION

Drive rolls turn, but wire will not feed of | 1. Gun cable kinked and/or twisted. | |

wire feeding is rough |

| Keep as straight as possible. Inspect |

| cable and replace if necessary. | |

|

| |

| 2. | Wire jammed in gun and cable. |

|

| Remove wire from gun and cable |

|

| — feed in new wire. Note any obstruc- |

|

| tion. Replace liner if necessary |

| 3. | Incorrect drive rolls and guide tubes. |

|

| Be sure the wire diameter being used is |

|

| stamped on drive rolls and guide tubes. |

|

| Replace if necessary |

| 4. | Gun cable liner dirty. |

|

| Clean liner or replace. |

| 5. | Worn drive rolls. |

|

| Replace or reverse split drive roll type. |

| 6. | Electrode rusty and/or dirty. |

|

| Replace or electrode if it is rusty. |

| 7. | Worn or improper size cable liner. |

|

| Replace cable liner. |

| 8. | Partially flashed, melted or improper |

|

| size contact tip. Replace the contact tip. |

|

| |

Variable or “hunting” arc | 1. Contact tip worn or incorrect size. | |

|

| Replace contact tip. |

| 2. Worn or undersize ground cables or | |

|

| poor ground connections. |

|

| Inspect — repair or replace as neces |

|

| sary. |

| 3. Loose electrode connections. | |

|

| Be sure the following connections are |

|

| tight: electrode cable to wire feeder and |

|

| power source, work cable to power |

|

| source and work, gun cable to wire |

|

| feeder contact tip to nozzle. |

|

| |

Poor arc striking with sticking or | 1. Improper procedures or techniques. | |

weld porosity, narrow and ropy looking |

| See “Gas Metal Arc Welding Guide” |

bead, or electrode stubbing into plate |

| |

while welding |

| Improper gas shielding. |

|

| Clean gas cone. Make certain that gas |

|

| diffuser is not restricted. Make certain |

|

| that gas cylinder is not empty or turned |

|

| off. Make certain gas solenoid valve is |

|

| operating and gas flow rate is proper. |

|

| Remove gun liner and check rubber |

|

| seal for any sign of deterioration or |

|

| damage. Be sure set screw in brass |

|

| connector is in place and tightened |

|

| against the liner bushing. |

|

| |

Tip seizes in diffuser | 1. Tip overheating due to prolonged or | |

|

| excessive high current and/or duly |

|

| cycle welding. |

|

| Do not exceed current and duly cycle |

|

| rating of gun. |

|

| A light application of high temperature |

|

| antiseize lubricant (such as Lincoln |

|

| E2607 Graphic Grease) may be applied |

|

| to tip threads. |

|

|

|

If all recommended possible areas of misadjustment have been checked and the problem persists,

Contact your local Lincoln Authorized Field Service Facility.

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

MAGNUM® & MAGNUM® PRO CURVE 200 GUNS