INSTALLATION |

CONNECTION DIAGRAMS

GTAW (TIG) WELDING

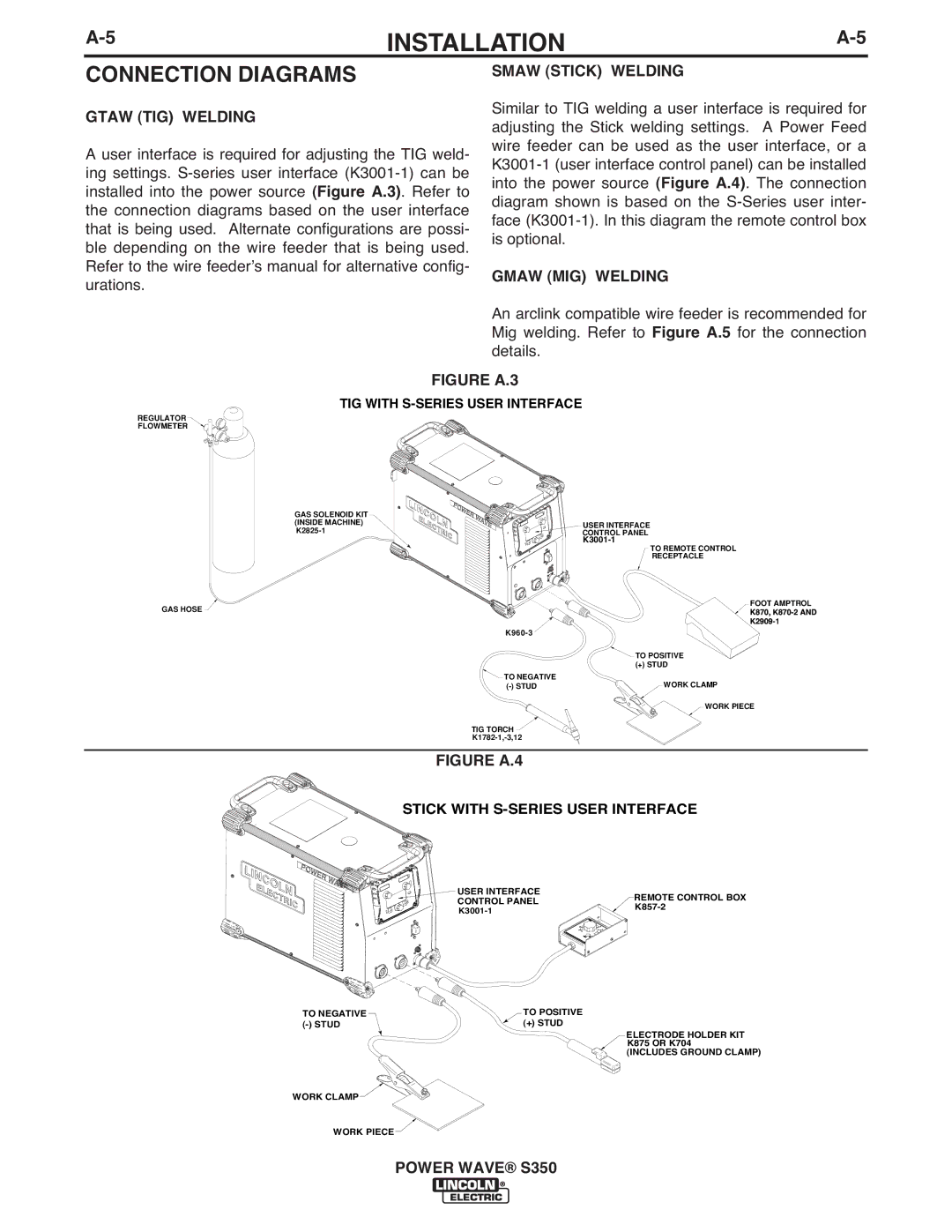

A user interface is required for adjusting the TIG weld- ing settings.

SMAW (STICK) WELDING

Similar to TIG welding a user interface is required for adjusting the Stick welding settings. A Power Feed wire feeder can be used as the user interface, or a

GMAW (MIG) WELDING

An arclink compatible wire feeder is recommended for Mig welding. Refer to Figure A.5 for the connection details.

FIGURE A.3

TIG WITH S-SERIES USER INTERFACE

REGULATOR

FLOWMETER

GAS SOLENOID KIT (INSIDE MACHINE)

GAS HOSE ![]()

USER INTERFACE

CONTROL PANEL

TO REMOTE CONTROL

RECEPTACLE

FOOT AMPTROL

K870,

![]() TO POSITIVE

TO POSITIVE ![]()

![]()

(+) STUD

![]() TO NEGATIVE

TO NEGATIVE

WORK CLAMP |

WORK PIECE

TIG TORCH ![]()

FIGURE A.4

STICK WITH S-SERIES USER INTERFACE

TO NEGATIVE

USER INTERFACE

CONTROL PANEL

TO POSITIVE

(+) STUD

REMOTE CONTROL BOX ![]()

ELECTRODE HOLDER KIT K875 OR K704 (INCLUDES GROUND CLAMP)

WORK CLAMP

WORK PIECE

POWER WAVE® S350