81-286 specifications

Lochinvar 81-286 is a highly efficient and innovative heating solution that represents the latest advancements in boiler technology. This model, part of Lochinvar's prestigious line-up, is designed for commercial applications, delivering superior performance while emphasizing energy efficiency and user-friendly operation.One of the standout features of the Lochinvar 81-286 is its robust construction. Built with high-quality materials, the unit is engineered for durability and reliability, ensuring long-term operation with minimal maintenance. Its compact design allows for versatility in installation, making it suitable for various building layouts and configurations.

The boiler's primary technology is its advanced condensing capability, which optimizes heat transfer and reduces energy consumption. By efficiently using the heat generated during combustion, the 81-286 can achieve higher thermal efficiencies, often surpassing traditional systems. This results in lower operating costs and reduced greenhouse gas emissions, aligning with the growing demand for sustainable energy solutions in commercial buildings.

Lochinvar incorporates intelligent control systems into the 81-286, featuring user-friendly interfaces that facilitate straightforward programming and monitoring. These control systems enable precise regulation of temperature and pressure, ensuring optimal operation while providing real-time feedback that aids in troubleshooting and maintenance. Users can enjoy the convenience of remote monitoring, enhancing the overall user experience.

Another key characteristic of the Lochinvar 81-286 is its capacity range. The model is available in various sizes, allowing it to meet the specific demands of different facilities, from small businesses to large industrial applications. This flexibility makes it a top choice for contractors and engineers seeking reliable heating solutions that cater to diverse needs.

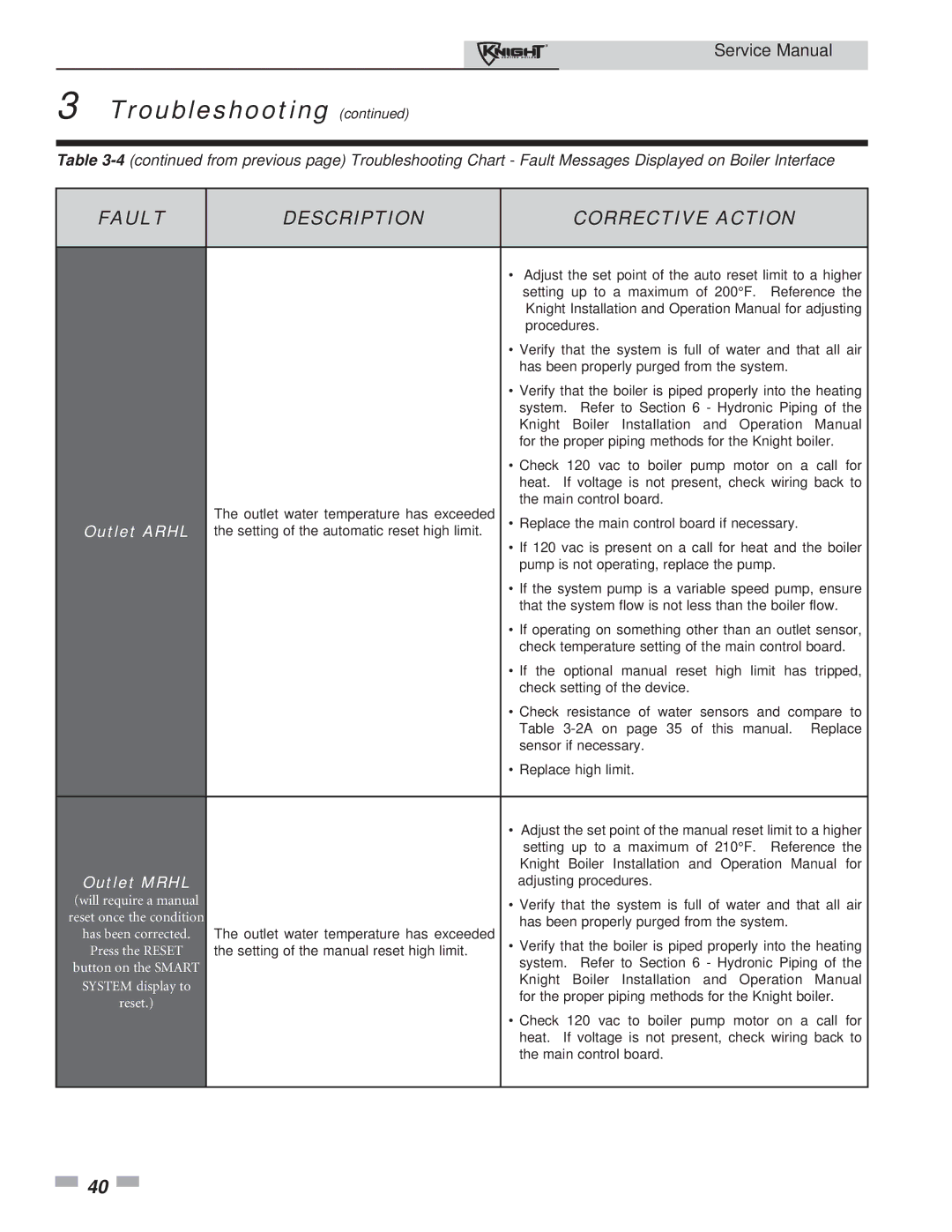

In addition, the Lochinvar 81-286 boasts exceptional safety features, including built-in safeguards that protect against overheating and pressure surges. These aspects ensure that the unit operates within safe parameters, providing peace of mind for facility managers and operators.

In summary, the Lochinvar 81-286 combines durability, efficiency, and advanced technology, making it an ideal solution for commercial heating needs. With its innovative condensing design, intelligent controls, and safety features, this boiler stands out as a reliable choice for those seeking sustainable and effective heating solutions. Its versatility and performance make it a key player in today’s ever-evolving energy landscape.