MAINTENANCE

•If the tool is operated continuously until the battery cartridge has discharged, allow the tool to rest for 15 minutes before proceeding with a fresh battery.

The fastening torque is affected by a wide variety of factors including the following. After fastening, always check the torque with a torque wrench.

1.When the battery cartridge is discharged almost com- pletely, voltage will drop and the fastening torque will be reduced.

2.Socket

•Failure to use the correct size socket will cause a reduction in the fastening torque.

•A worn socket ( wear on the hex end or square end ) will cause a reduction in the fastening torque.

3.Bolt

•Even though the torque coefficient and the class of bolt are the same, the proper fastening torque will differ according to the diameter of bolt.

•Even though the diameters of bolts are the same, the proper fastening torque will differ according to the torque coefficient, the class of bolt and the bolt length.

4.The manner of holding the tool or the material of driving position to be fastened will affect the torque.

5.Operating the tool at low speed will cause a reduction in the fastening torque.

CAUTION:

•Always be sure that the tool is switched off and the battery cartridge is removed before attempting to perform inspection or maintenance.

001145 |

1 |

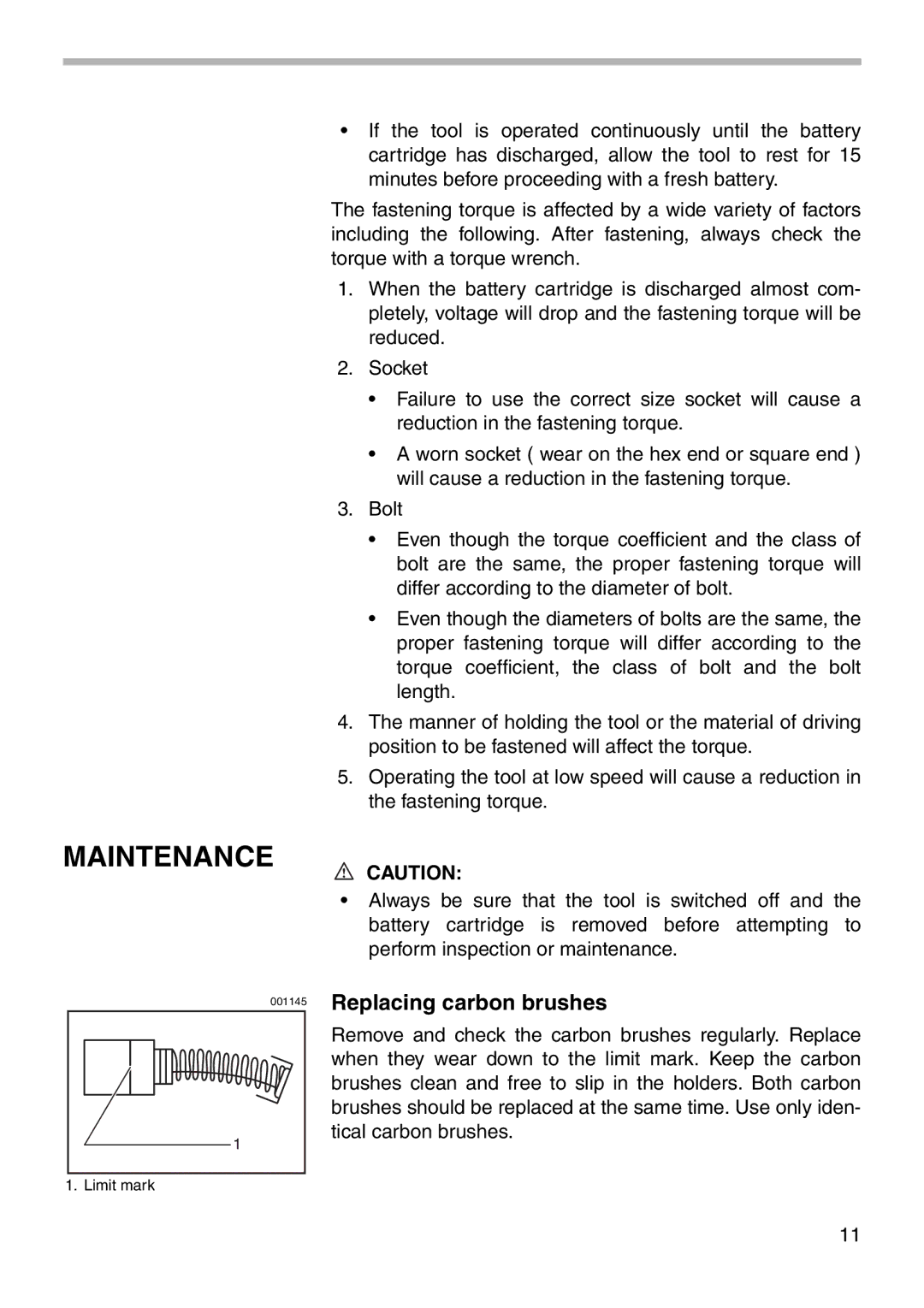

1. Limit mark

Replacing carbon brushes

Remove and check the carbon brushes regularly. Replace when they wear down to the limit mark. Keep the carbon brushes clean and free to slip in the holders. Both carbon brushes should be replaced at the same time. Use only iden- tical carbon brushes.

11