Bit angle (when chipping, scaling or demolishing)

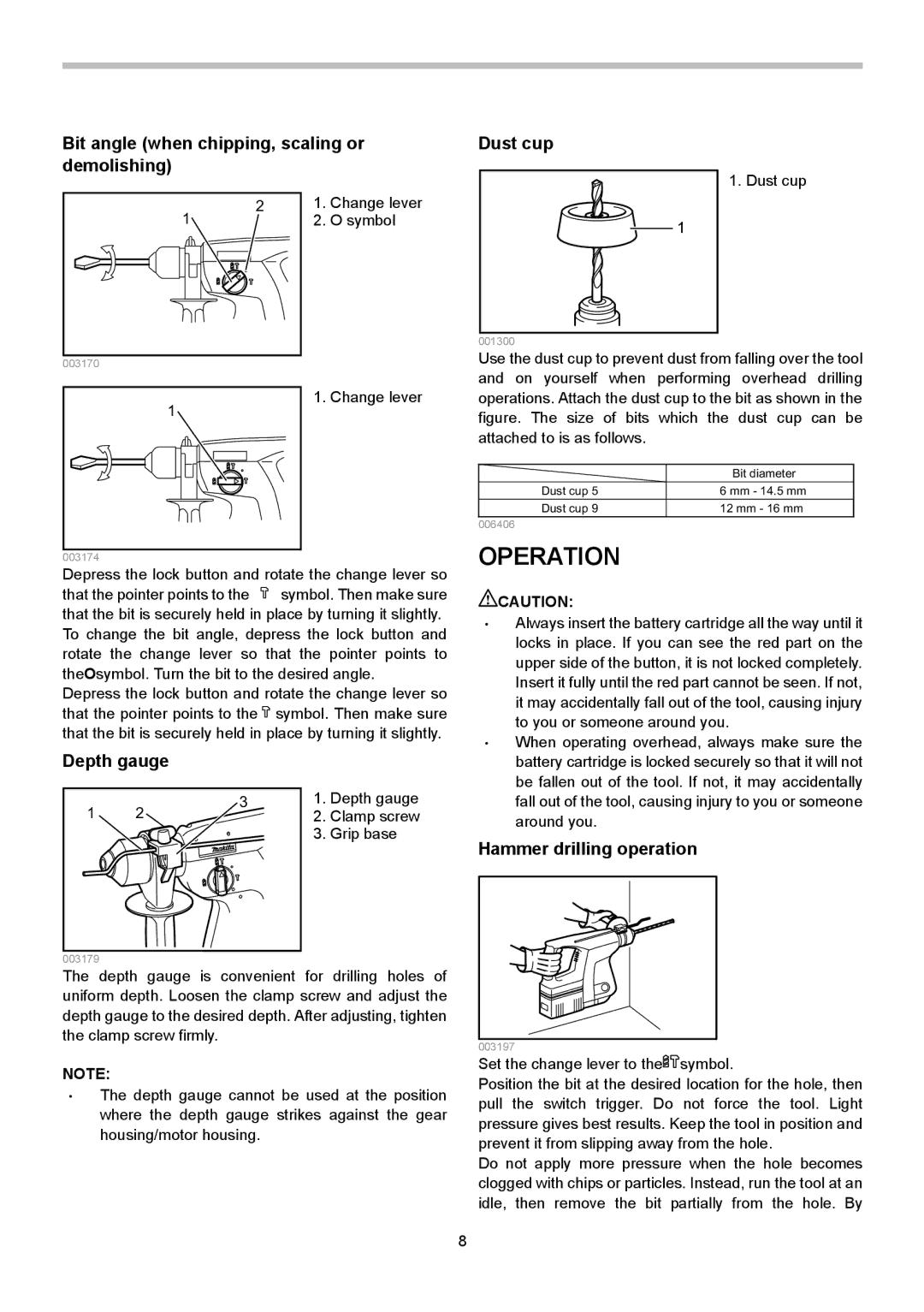

Dust cup

1. Dust cup

2 |

1 |

003170 |

1 |

1.Change lever

2.O symbol

1. Change lever

1

001300

Use the dust cup to prevent dust from falling over the tool and on yourself when performing overhead drilling operations. Attach the dust cup to the bit as shown in the figure. The size of bits which the dust cup can be attached to is as follows.

| Bit diameter |

Dust cup 5 | 6 mm - 14.5 mm |

Dust cup 9 | 12 mm - 16 mm |

006406

003174

Depress the lock button and rotate the change lever so

that the pointer points to the ![]() symbol. Then make sure that the bit is securely held in place by turning it slightly. To change the bit angle, depress the lock button and rotate the change lever so that the pointer points to theOsymbol. Turn the bit to the desired angle.

symbol. Then make sure that the bit is securely held in place by turning it slightly. To change the bit angle, depress the lock button and rotate the change lever so that the pointer points to theOsymbol. Turn the bit to the desired angle.

Depress the lock button and rotate the change lever so that the pointer points to the ![]() symbol. Then make sure that the bit is securely held in place by turning it slightly.

symbol. Then make sure that the bit is securely held in place by turning it slightly.

Depth gauge

| 3 | 1. Depth gauge |

1 | 2 | 2. Clamp screw |

|

| 3. Grip base |

OPERATION

![]() CAUTION:

CAUTION:

•Always insert the battery cartridge all the way until it locks in place. If you can see the red part on the upper side of the button, it is not locked completely. Insert it fully until the red part cannot be seen. If not, it may accidentally fall out of the tool, causing injury to you or someone around you.

•When operating overhead, always make sure the battery cartridge is locked securely so that it will not be fallen out of the tool. If not, it may accidentally fall out of the tool, causing injury to you or someone around you.

Hammer drilling operation

003179

The depth gauge is convenient for drilling holes of uniform depth. Loosen the clamp screw and adjust the depth gauge to the desired depth. After adjusting, tighten the clamp screw firmly.

NOTE:

•The depth gauge cannot be used at the position where the depth gauge strikes against the gear housing/motor housing.

003197

Set the change lever to the![]() symbol.

symbol.

Position the bit at the desired location for the hole, then pull the switch trigger. Do not force the tool. Light pressure gives best results. Keep the tool in position and prevent it from slipping away from the hole.

Do not apply more pressure when the hole becomes clogged with chips or particles. Instead, run the tool at an idle, then remove the bit partially from the hole. By

8