STORAGE

'When storing the machine for a icng time drain the fuel from the fuel tank and cdrbLretor as follows

1Drain all fuel from the fuel tank Gently push on the primer pump repeatedly iintrl all fuel IS expelled out of the primer pump Properly dispose of the fuel in accordance with all local laws

2Remove the spark aluy and add a few drops of oil into the spark plug hole Then pull the starter geMy to assure that dn oil ;ilm coats the engine inside, then insert and tighten the S D k~ d u g

3Clear or olow any dirt or dust from the nylon cutting head and engine housing wpe them with an

REASSEMBLY 1NSTRUCTlONS

Brush Cutter RBC2.52 and String Trimmer RBC253

Reassembling t h e drive s h a f t and t h e engine.

The shaft and the engine on this machine have been assembled in the factory. If you remove the shaft (example,for maintenavce) carefully reassemble it as shown beI ow:

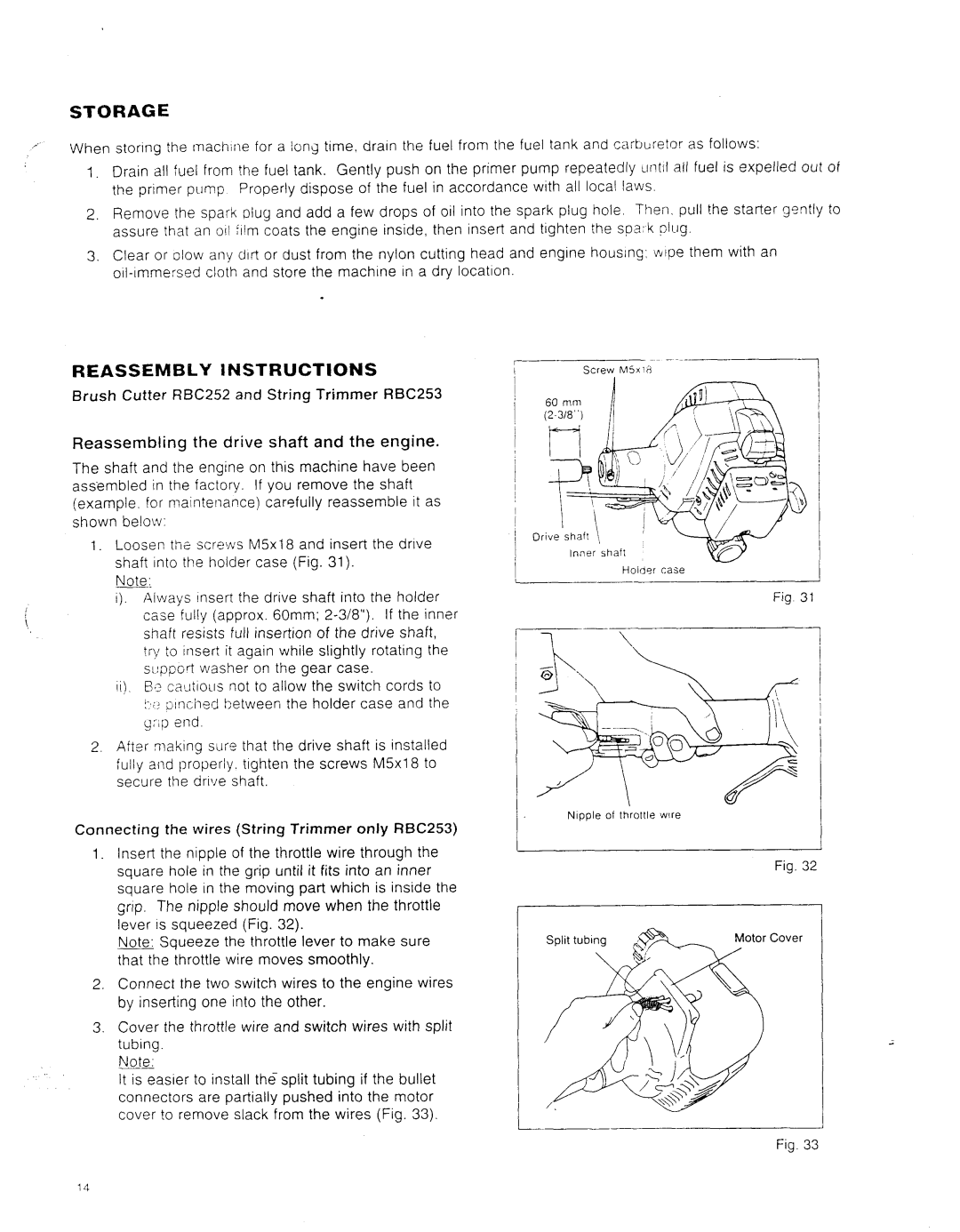

1 . Loosen the screws M5x18 and insert the drive shaft into the holder case (Fig. 31).

Note:

i) . | Always inserr the drive shaft into the holder | |

i | case fully (approx.60mm; | |

shaft resists full insertion of the drive shaft, | ||

| ||

| try to insert it again while slightly rotating the | |

| siqport washer on the gear case. | |

i i ) . | 5~2caiitio~isnot to allow the switch cords to | |

| !:;: ;jinih;d between the holder case and the | |

| gt1iend. |

2.After making scire that the drive shaft is installed fully and properly. tighten the screws M5x18 to secure the drive shaft.

Connecting the wires (String Trimmer only RBC253)

1 . Insert the nipple of the throttle wire through the square hole in the grip until it fits into an inner square hole in the moving part which is inside the grip. The nipple should move when the throttle

lever is squeezed (Fig. 32).

Note: Squeeze the throttle lever to make sure that the throttle wire moves smoothly.

j

I~

I

I

I~

Hoidsr case

Fig 31

i-

1 . | throttle wire |

Nipple of |

Fig. 32

2.Connect the two switch wires to the engine wires by inserting one into the other.

3.Cover the throttle wire and switch wires with split tubing.

_Note:-

It is easier to install the split tubing if the bullet connectors are partially pushed into the motor cover to remove slack from the wires (Fig. 33).

Fig. 3:

14