30

006928

−After sharpening the chain, check the height of the depth gauge using the chain gauge tool (optional accessory).

014344 |

−Remove any projecting material, however small, with a special flat file (optional accessory).

−Round off the front of the depth gauge again.

Cleaning the guide bar and lubricating the return sprocket

![]() CAUTION:

CAUTION:

•Always wear safety gloves for this task. Burrs present a risk of injury.

006930

Check the running surfaces of the bar regularly for damage. Clean using a suitable tool, and remove burrs if necessary.

If the chain saw receives frequent use, lubricate the return sprocket bearing at least once a week. Before adding new fresh grease, carefully clean the 2 mm hole on the tip of the guide bar, then force a small quantity of

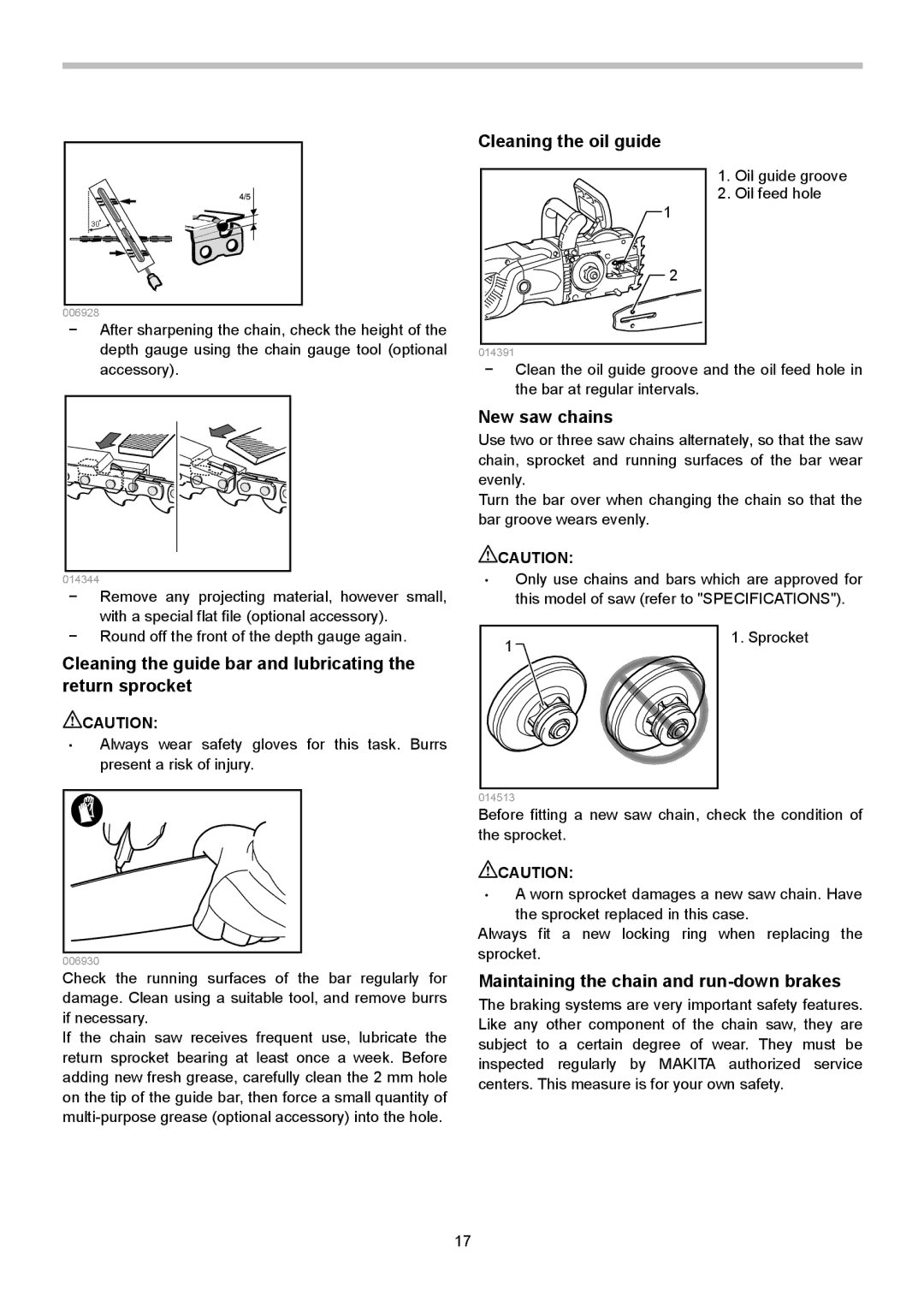

Cleaning the oil guide

1. Oil guide groove

2. Oil feed hole

1

![]() 2

2

014391

−Clean the oil guide groove and the oil feed hole in the bar at regular intervals.

New saw chains

Use two or three saw chains alternately, so that the saw chain, sprocket and running surfaces of the bar wear evenly.

Turn the bar over when changing the chain so that the bar groove wears evenly.

![]() CAUTION:

CAUTION:

•Only use chains and bars which are approved for this model of saw (refer to "SPECIFICATIONS").

1 | 1. Sprocket |

|

014513

Before fitting a new saw chain, check the condition of the sprocket.

![]() CAUTION:

CAUTION:

•A worn sprocket damages a new saw chain. Have the sprocket replaced in this case.

Always fit a new locking ring when replacing the sprocket.

Maintaining the chain and run-down brakes

The braking systems are very important safety features. Like any other component of the chain saw, they are subject to a certain degree of wear. They must be inspected regularly by MAKITA authorized service centers. This measure is for your own safety.

17