10.Connect the dryer power cord to 120 volt AC outlet for gas models. 240 volt outlet for electric models.

Make appropriate external ground connection. See DETAILED Installation Instructions for

ELECTRICAL REQUIRE- MENTS AND GROUNDING (pages

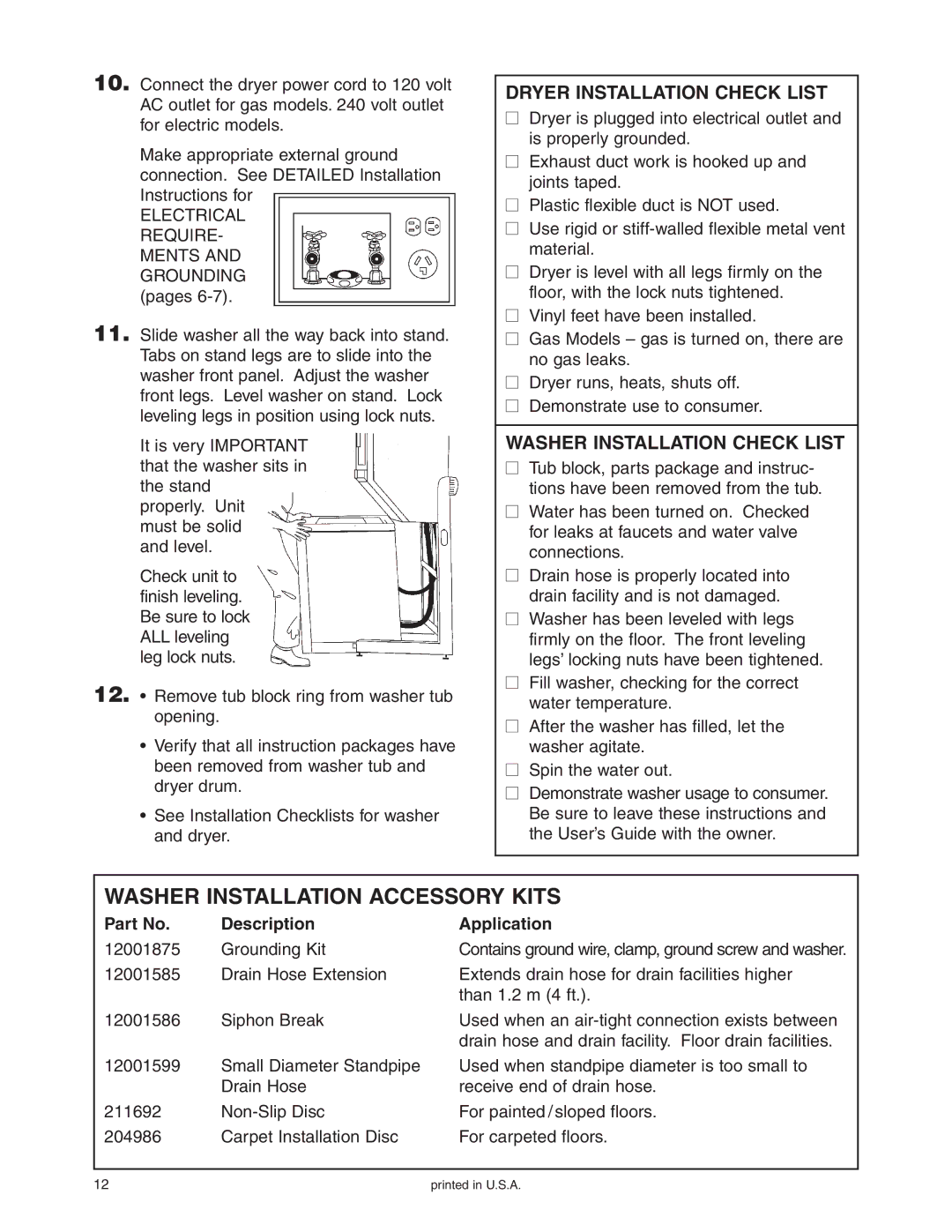

11.Slide washer all the way back into stand. Tabs on stand legs are to slide into the washer front panel. Adjust the washer front legs. Level washer on stand. Lock leveling legs in position using lock nuts.

It is very IMPORTANT that the washer sits in the stand

properly. Unit must be solid and level.

Check unit to finish leveling. Be sure to lock ALL leveling leg lock nuts.

12.• Remove tub block ring from washer tub opening.

•Verify that all instruction packages have been removed from washer tub and dryer drum.

•See Installation Checklists for washer and dryer.

DRYER INSTALLATION CHECK LIST

■Dryer is plugged into electrical outlet and is properly grounded.

■Exhaust duct work is hooked up and joints taped.

■Plastic flexible duct is NOT used.

■Use rigid or

■Dryer is level with all legs firmly on the floor, with the lock nuts tightened.

■Vinyl feet have been installed.

■Gas Models – gas is turned on, there are no gas leaks.

■Dryer runs, heats, shuts off.

■Demonstrate use to consumer.

WASHER INSTALLATION CHECK LIST

■Tub block, parts package and instruc- tions have been removed from the tub.

■Water has been turned on. Checked for leaks at faucets and water valve connections.

■Drain hose is properly located into drain facility and is not damaged.

■Washer has been leveled with legs firmly on the floor. The front leveling legs’ locking nuts have been tightened.

■Fill washer, checking for the correct water temperature.

■After the washer has filled, let the washer agitate.

■Spin the water out.

■Demonstrate washer usage to consumer. Be sure to leave these instructions and the User’s Guide with the owner.

WASHER INSTALLATION ACCESSORY KITS

Part No. | Description | Application |

12001875 | Grounding Kit | Contains ground wire, clamp, ground screw and washer. |

12001585 | Drain Hose Extension | Extends drain hose for drain facilities higher |

|

| than 1.2 m (4 ft.). |

12001586 | Siphon Break | Used when an |

|

| drain hose and drain facility. Floor drain facilities. |

12001599 | Small Diameter Standpipe | Used when standpipe diameter is too small to |

| Drain Hose | receive end of drain hose. |

211692 | For painted /sloped floors. | |

204986 | Carpet Installation Disc | For carpeted floors. |

12 | printed in U.S.A. |