D.Conveyor Installation

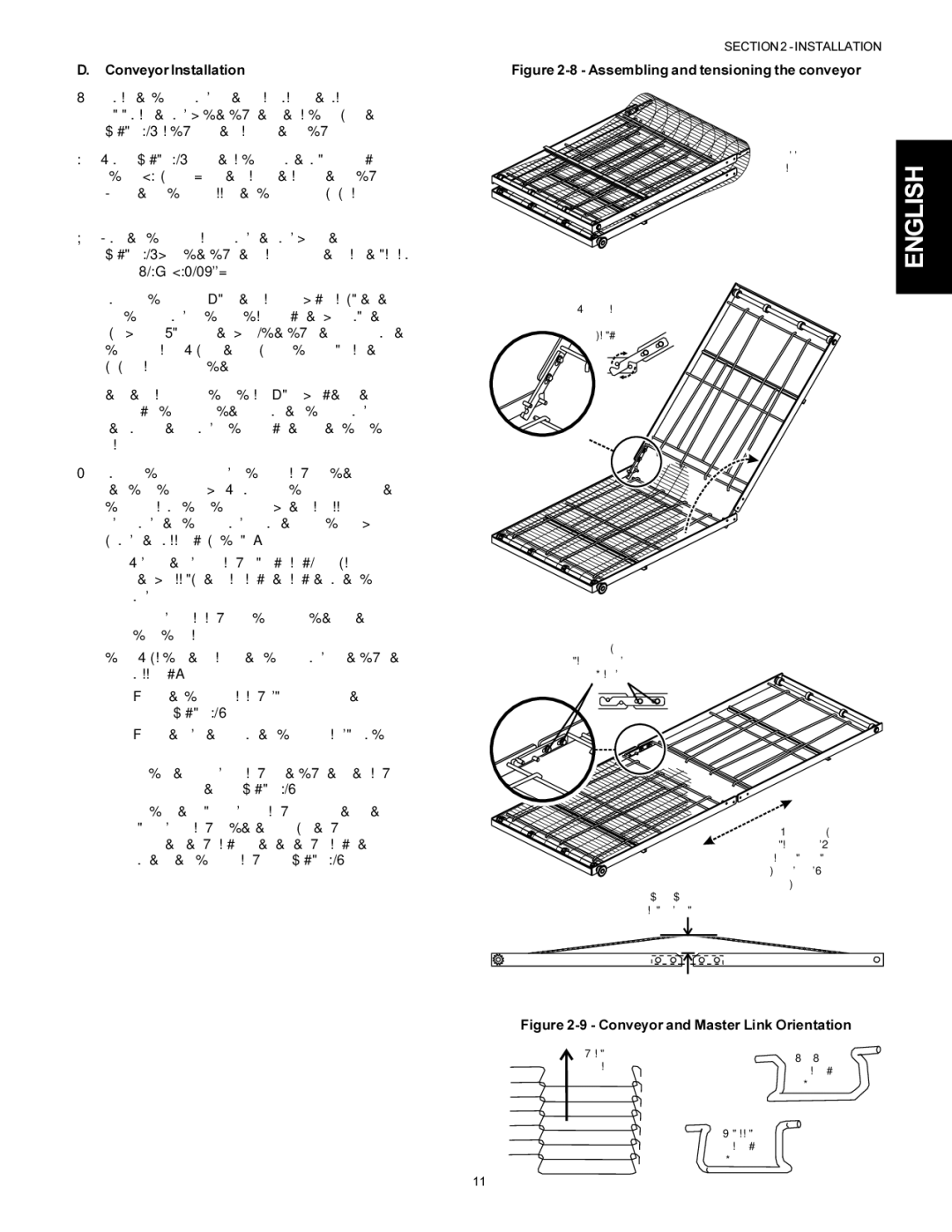

1.Unfold the conveyor frame so that it lies flat on the floor. As you unfold the frame, check that the locator pins shown in Figure

2.Refer to Figure

3.Lift the conveyor belt away from the frame, as shown in Figure

If it is necessary to adjust the belt tension, gently push the two conveyor frame sections closer together, or further apart, as required. Then,

4.When the belt tension is correctly adjusted, tighten the two tensioning screws on each side of the conveyor frame. This fastens the two frame sections together at the correct belt tension.

5.If it is necessary to add or remove conveyor links to achieve the correct tension, OR if it is necessary to reverse the conveyor belt for correct orientation, the belt will need to be removed from the conveyor frame. If this is necessary, perform the following procedure:

a.Remove the master links using

b.Add or remove belt links as necessary to achieve the correct belt tension.

c.Replace the belt on the conveyor frame. Check the following:

•The conveyor belt links must be oriented as shown in Figure

•The smooth side of the conveyor belt must face UP.

d.Connect the inside master links. Check that the links are oriented as shown in Figure

e.Connect the outside master links. Note that the outside master links each have an open hook on one side. This hook aligns with the hooks along the sides of the other conveyor links. See Figure

SECTION 2 - INSTALLATION

Figure 2-8 - Assembling and tensioning the conveyor

Folded | ENGLISH |

frame | |

|

Pins on frame

fit into slots on bracket

Tensioning

screws in slotted holes (2 per side)

With tensioning

screws loosened,

frame sections can be moved to adjust belt tension

vertical deflection

Figure 2-9 - Conveyor and Master Link Orientation

Direction | CORRECT | |

of travel | ||

master link | ||

| ||

| position |

Incorrect master link position

11