Exhaust connections

Calculation of exhaust ducting

A pipe diameter of 5" should ensure

Determine the total pipe length as fol- lows:

Measure the total length of ducting needed.

Add the length of additional ducting to this figure according to the num- ber and type of bends (see table below).

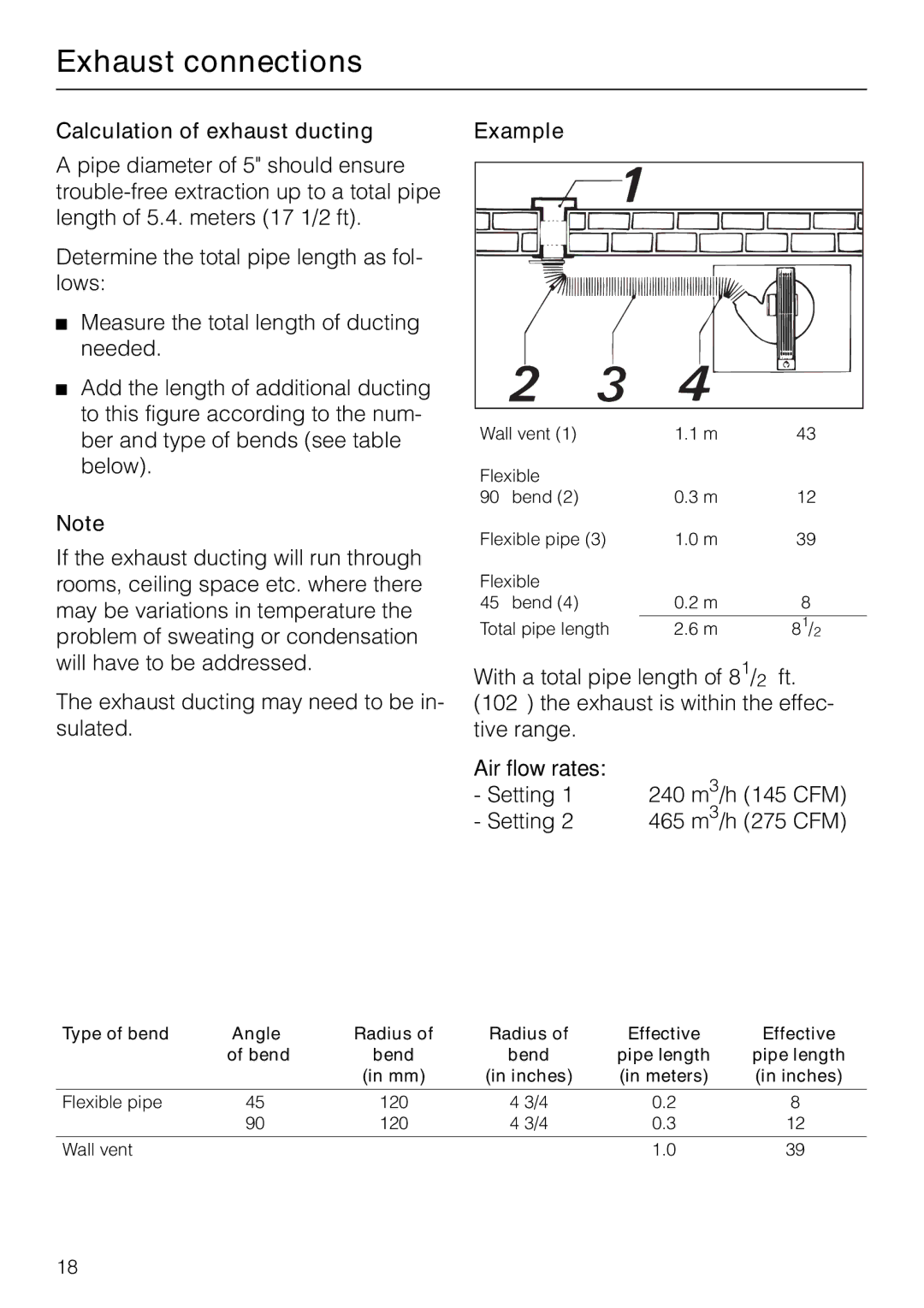

Example |

Wall vent (1) | 1.1 m | 43’’ |

Flexible |

|

|

90° bend (2) | 0.3 m | 12’’ |

Note

If the exhaust ducting will run through rooms, ceiling space etc. where there may be variations in temperature the problem of sweating or condensation will have to be addressed.

The exhaust ducting may need to be in- sulated.

Flexible pipe (3) | 1.0 m | 39’’ |

Flexible |

|

|

45° bend (4) | 0.2 m | 8’’ |

|

|

|

Total pipe length | 2.6 m | 81/2’’ |

With a total pipe length of 81/2 ft. (102’’) the exhaust is within the effec- tive range.

Air flow rates:

- Setting 1 240 m3/h (145 CFM)

- Setting 2 465 m3/h (275 CFM)

Type of bend | Angle | Radius of | Radius of | Effective | Effective |

| of bend | bend | bend | pipe length | pipe length |

|

| (in mm) | (in inches) | (in meters) | (in inches) |

|

|

|

|

|

|

Flexible pipe | 45° | 120 | 4 3/4 | 0.2 | 8’’ |

| 90° | 120 | 4 3/4 | 0.3 | 12’’ |

|

|

|

|

|

|

Wall vent |

|

|

| 1.0 | 39’’ |

18