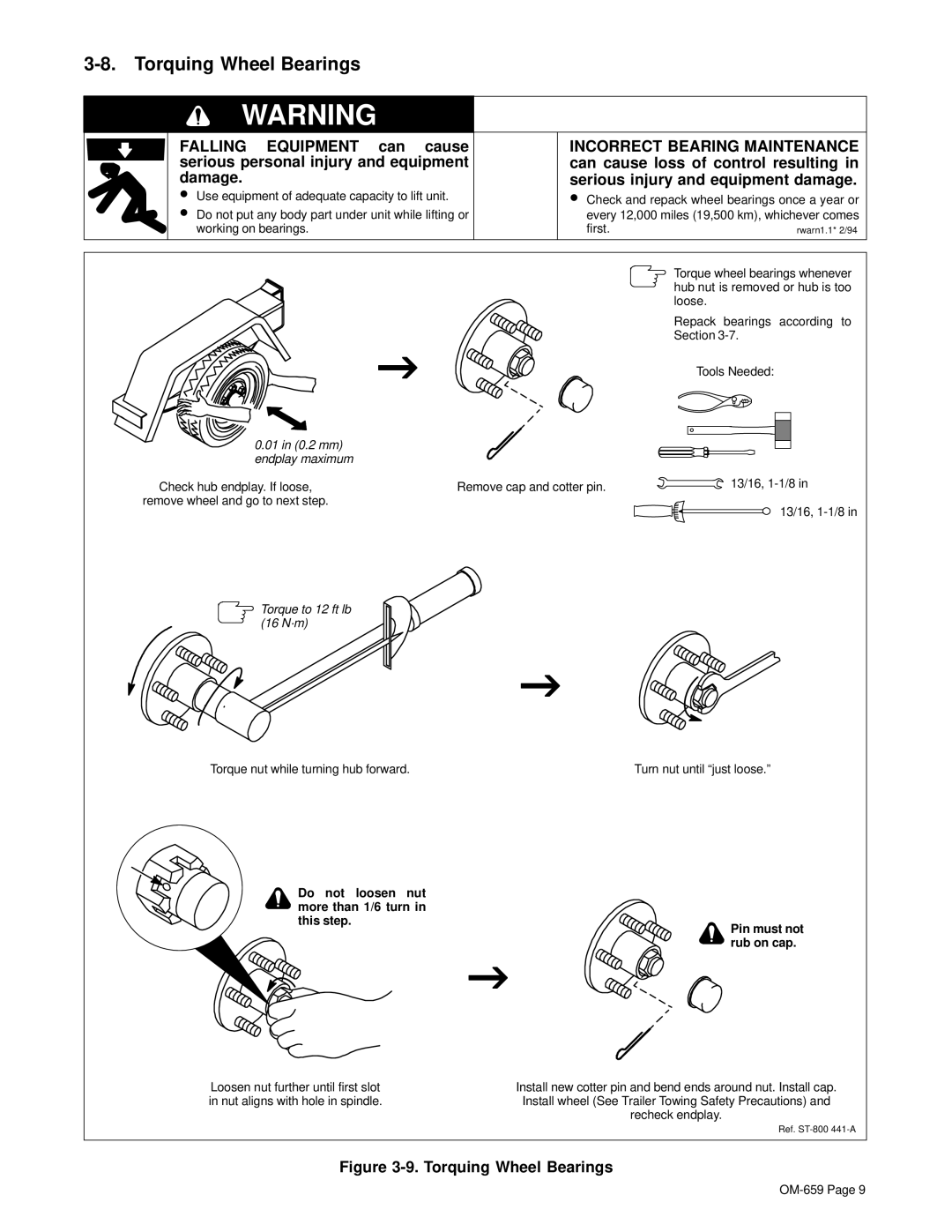

Turn nut until “just loose.”

Torque wheel bearings whenever hub nut is removed or hub is too loose.

Repack bearings according to Section 3-7.

Tools Needed:

3-8. Torquing Wheel Bearings

WARNING |

FALLING EQUIPMENT can cause | INCORRECT BEARING MAINTENANCE | ||

serious personal injury and equipment | can cause loss of control resulting in | ||

damage. | serious injury and equipment damage. | ||

• | Use equipment of adequate capacity to lift unit. | • Check and repack wheel bearings once a year or | |

• | Do not put any body part under unit while lifting or | every 12,000 miles (19,500 km), whichever comes | |

| working on bearings. | first. | rwarn1.1* 2/94 |

0.01in (0.2 mm) endplay maximum

Check hub endplay. If loose, | Remove cap and cotter pin. | 13/16, |

remove wheel and go to next step. |

|

|

Torque to 12 ft lb (16 N·m)

Torque nut while turning hub forward.

Do not loosen nut more than 1/6 turn in this step.

13/16, 1-1/8 in

Pin must not rub on cap.

Loosen nut further until first slot | Install new cotter pin and bend ends around nut. Install cap. |

in nut aligns with hole in spindle. | Install wheel (See Trailer Towing Safety Precautions) and |

| recheck endplay. |

| Ref. |