3-6. Installing Welding Generator

WARNING |

|

|

| FALLING EQUIPMENT | can cause |

|

| TILTING OF TRAILER can result in | ||||||

|

|

| |||||||||||

|

|

| serious personal injury and equipment |

|

| personal injury or equipment damage. | |||||||

|

|

| damage. |

|

|

| • | Install welding generator onto trailer with engine end | |||||

|

|

| • | Use lifting eye to lift unit only, NOT running gear, gas |

|

| • | toward hitch end of trailer. | |||||

|

|

|

|

| |||||||||

|

|

|

| cylinders, trailer, or any other heavy options, |

|

| Distribute weight so trailer tongue weight is | ||||||

|

|

| • | accessories, or devices. |

|

|

| • | approximately 10% of the gross trailer weight. | ||||

|

|

| Use equipment of adequate capacity to lift the unit. |

|

| Use adequate blocks or lifting device to support | |||||||

|

|

|

|

|

|

|

|

|

| hitch end while pivoting trailer jack into position (see | |||

|

|

|

|

|

|

|

|

| • | Section |

|

| |

|

|

|

|

|

|

|

|

| Use trailer jack to obtain desired height and to | ||||

|

|

|

|

|

|

|

|

|

| support tongue weight while installing welding | |||

|

|

|

|

|

|

|

|

|

| generator. |

| rwarn1.1* 3/93 | |

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

| Support trailer with jack. Apply | |

|

|

|

|

|

|

|

|

|

|

|

| parking brake. | |

|

|

|

|

|

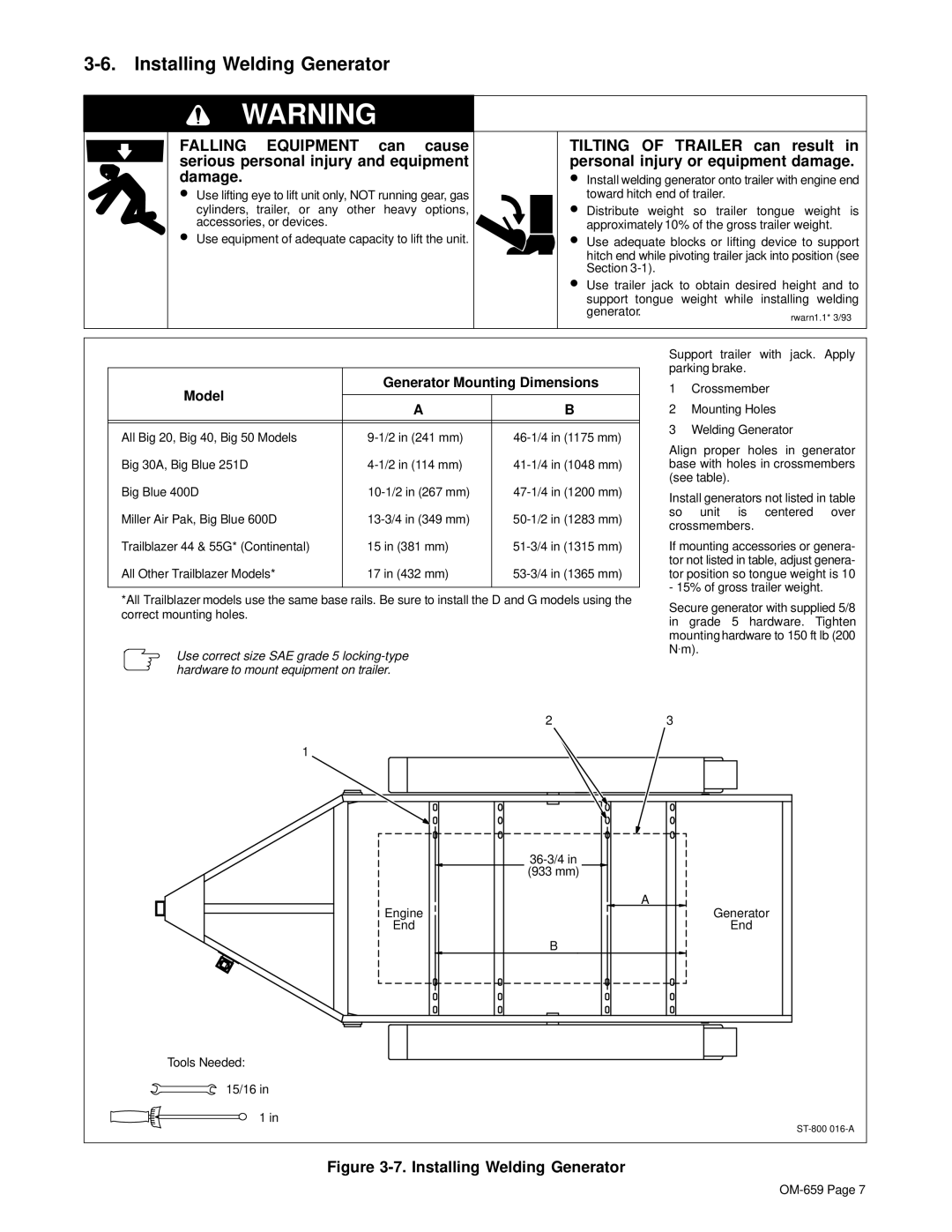

| Generator Mounting Dimensions |

| ||||||

|

|

| Model |

|

| 1 | Crossmember | ||||||

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

| A |

|

| B |

|

| 2 | Mounting Holes | ||

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

| 3 | Welding Generator |

|

|

|

|

|

|

|

|

|

|

|

| ||

|

| All Big 20, Big 40, Big 50 Models |

|

| |||||||||

|

|

|

| Align proper holes in generator | |||||||||

|

|

|

|

|

|

|

|

|

|

|

| ||

|

| Big 30A, Big Blue 251D |

|

| base with holes in crossmembers | ||||||||

|

|

|

|

|

|

|

|

|

|

|

| (see table). | |

|

| Big Blue 400D |

|

| Install generators not listed in table | ||||||||

|

|

|

|

|

|

|

|

|

|

|

| ||

|

| Miller Air Pak, Big Blue 600D |

|

| so | unit is centered over | |||||||

|

|

|

| crossmembers. | |||||||||

|

|

|

|

|

|

|

|

|

|

|

| ||

|

| Trailblazer 44 & 55G* (Continental) |

| 15 in (381 mm) |

| If mounting accessories or genera- | |||||||

|

|

|

|

|

|

|

|

|

|

|

| tor not listed in table, adjust genera- | |

|

| All Other Trailblazer Models* |

| 17 in (432 mm) |

| tor position so tongue weight is 10 | |||||||

|

|

|

|

|

|

|

|

|

|

|

| - 15% of gross trailer weight. | |

|

|

|

|

|

|

|

|

|

|

|

| ||

*All Trailblazer models use the same base rails. Be sure to install the D and G models using the correct mounting holes.

Use correct size SAE grade 5

2

1

(933 mm)

Engine

End

B

Tools Needed:

15/16 in

1 in

3

A

Generator

End