‘

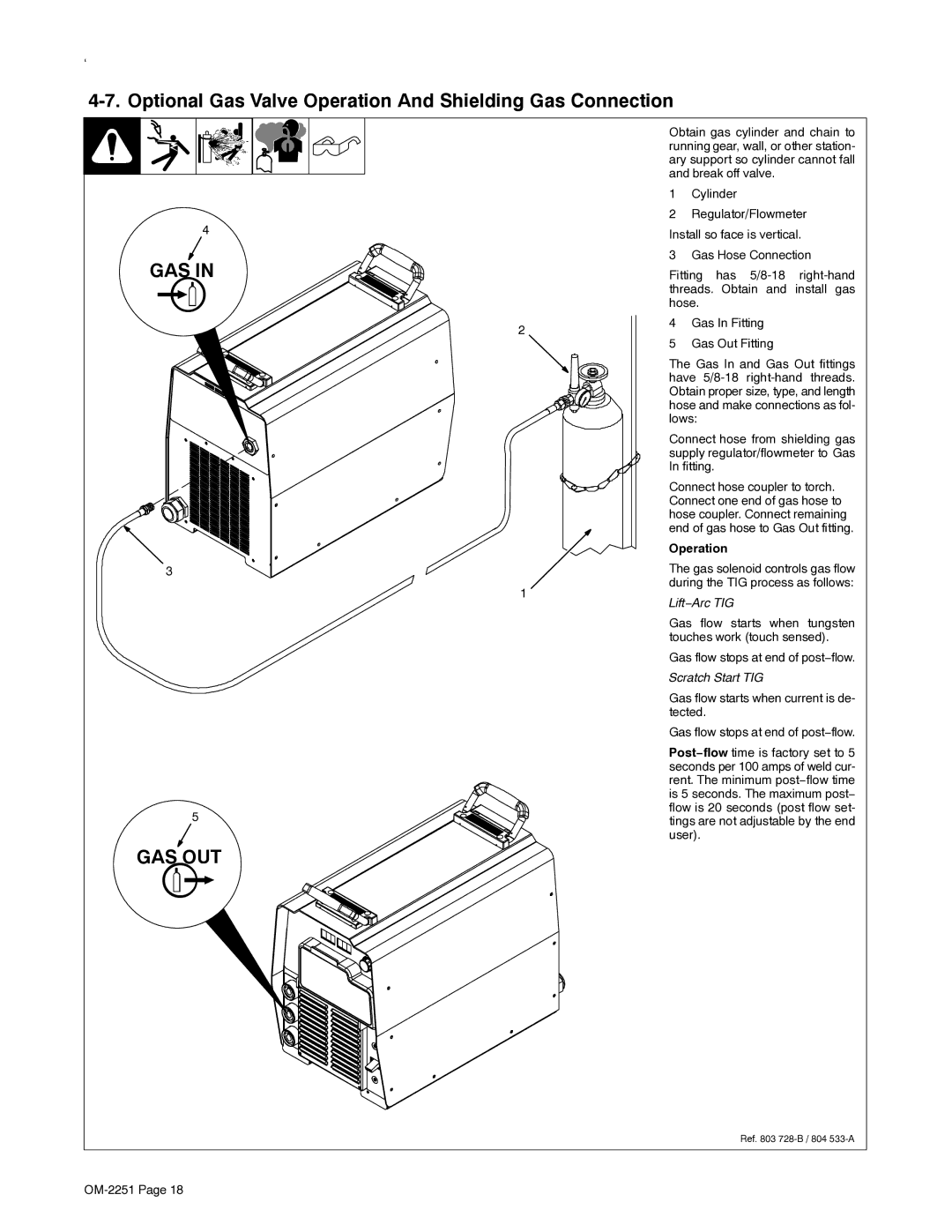

4-7. Optional Gas Valve Operation And Shielding Gas Connection

4

GAS IN

2

3

1

5

GAS OUT

Obtain gas cylinder and chain to running gear, wall, or other station- ary support so cylinder cannot fall and break off valve.

1Cylinder

2Regulator/Flowmeter Install so face is vertical.

3Gas Hose Connection

Fitting has

4Gas In Fitting

5Gas Out Fitting

The Gas In and Gas Out fittings have

Connect hose from shielding gas supply regulator/flowmeter to Gas In fitting.

Connect hose coupler to torch. Connect one end of gas hose to hose coupler. Connect remaining end of gas hose to Gas Out fitting.

Operation

The gas solenoid controls gas flow during the TIG process as follows:

Lift−Arc TIG

Gas flow starts when tungsten touches work (touch sensed).

Gas flow stops at end of post−flow.

Scratch Start TIG

Gas flow starts when current is de- tected.

Gas flow stops at end of post−flow.

Post−flow time is factory set to 5 seconds per 100 amps of weld cur- rent. The minimum post−flow time is 5 seconds. The maximum post− flow is 20 seconds (post flow set- tings are not adjustable by the end user).

Ref. 803