SECTION 5 − OPERATION

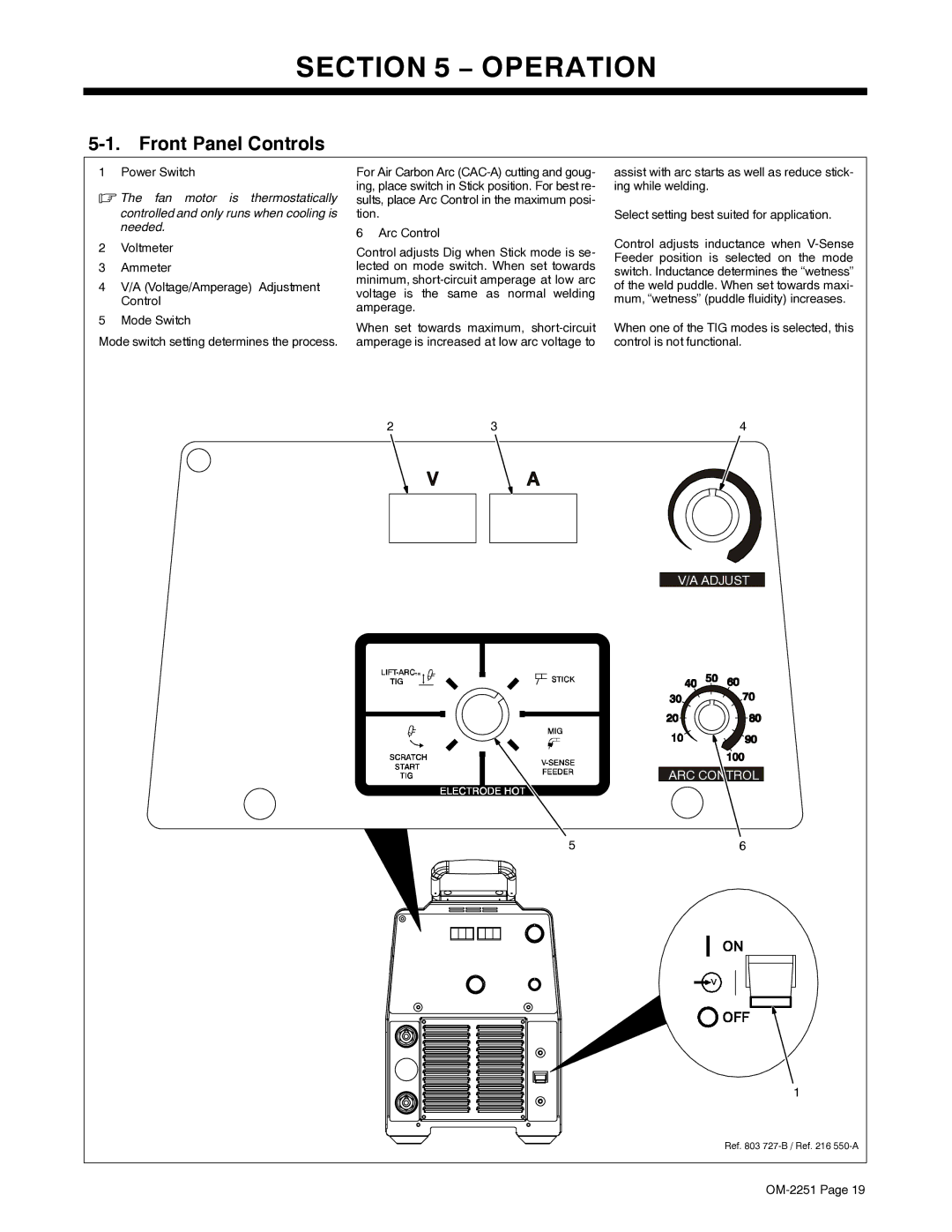

5-1. Front Panel Controls

1 Power Switch

.The fan motor is thermostatically

controlled and only runs when cooling is needed.

2Voltmeter

3Ammeter

4V/A (Voltage/Amperage) Adjustment Control

5Mode Switch

Mode switch setting determines the process.

For Air Carbon Arc | assist with arc starts as well as reduce stick- | |

ing, place switch in Stick position. For best re- | ing while welding. | |

sults, place Arc Control in the maximum posi- |

| |

tion. | Select setting best suited for application. | |

6 Arc Control | Control adjusts inductance when | |

Control adjusts Dig when Stick mode is se- | ||

Feeder position is selected on the mode | ||

lected on mode switch. When set towards | ||

switch. Inductance determines the “wetness” | ||

minimum, | ||

of the weld puddle. When set towards maxi- | ||

voltage is the same as normal welding | ||

mum, “wetness” (puddle fluidity) increases. | ||

amperage. | ||

| ||

When set towards maximum, | When one of the TIG modes is selected, this | |

amperage is increased at low arc voltage to | control is not functional. |

23

5