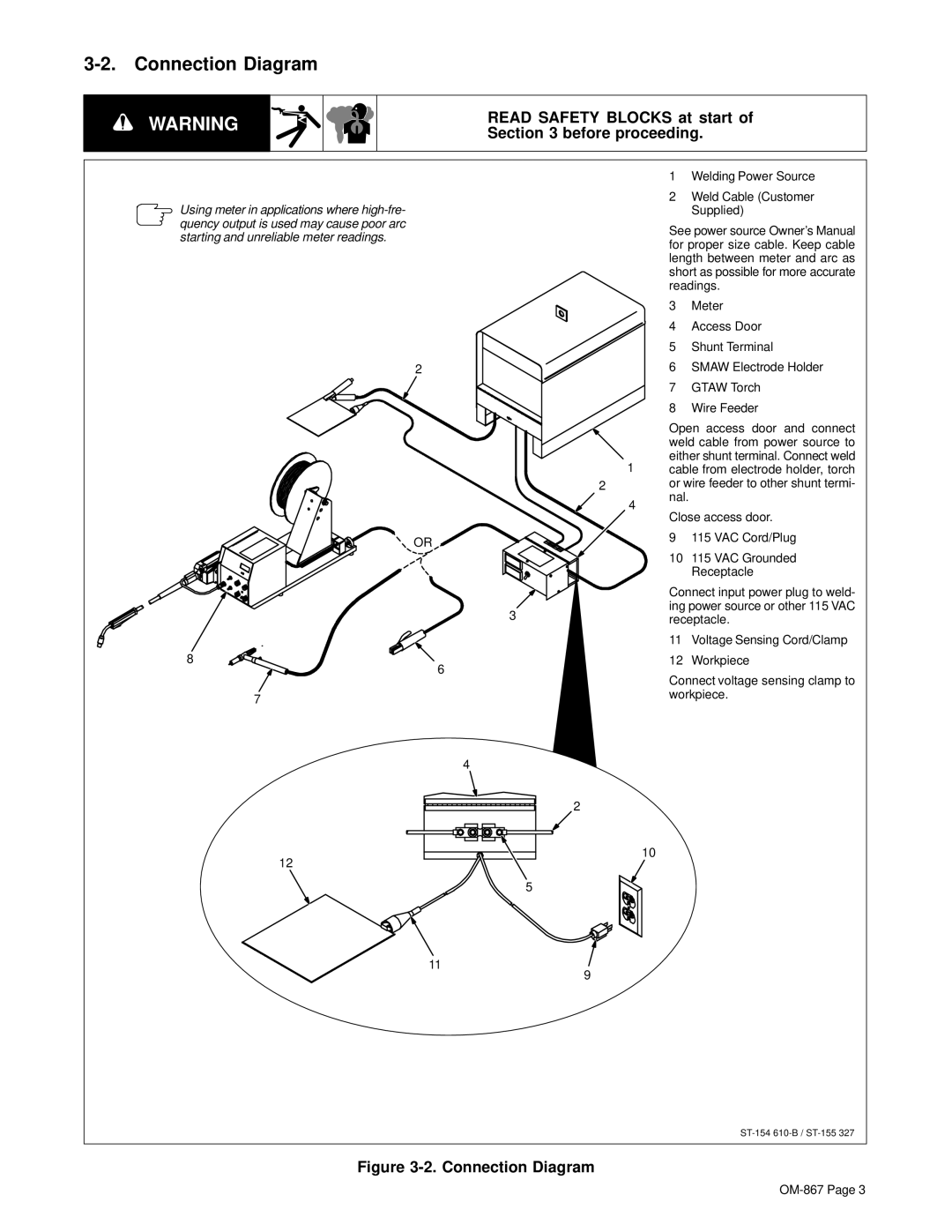

3-2. Connection Diagram

WARNING

READ SAFETY BLOCKS at start of Section 3 before proceeding.

Using meter in applications where

1Welding Power Source

2Weld Cable (Customer Supplied)

See power source Owner’s Manual for proper size cable. Keep cable length between meter and arc as short as possible for more accurate readings.

8

7

12

2

1

2

4

OR

3

6

4

2

10

5

3Meter

4Access Door

5Shunt Terminal

6SMAW Electrode Holder

7GTAW Torch

8Wire Feeder

Open access door and connect weld cable from power source to either shunt terminal. Connect weld cable from electrode holder, torch or wire feeder to other shunt termi- nal.

Close access door.

9115 VAC Cord/Plug

10115 VAC Grounded Receptacle

Connect input power plug to weld- ing power source or other 115 VAC receptacle.

11Voltage Sensing Cord/Clamp

12Workpiece

Connect voltage sensing clamp to workpiece.

11

9