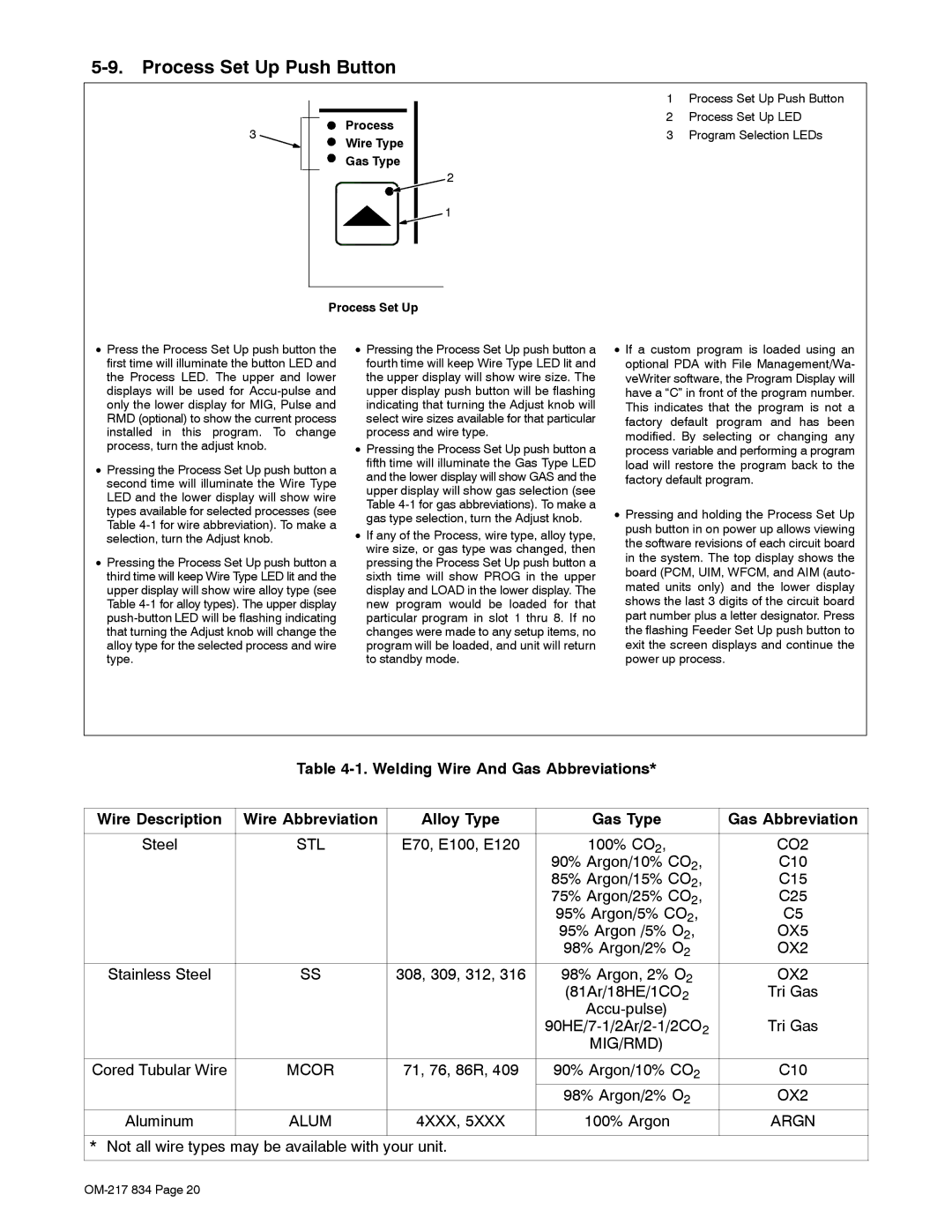

5-9. Process Set Up Push Button

3

Process |

Wire Type |

Gas Type |

2 |

1 |

Process Set Up

1Process Set Up Push Button

2Process Set Up LED

3Program Selection LEDs

•Press the Process Set Up push button the first time will illuminate the button LED and the Process LED. The upper and lower displays will be used for

•Pressing the Process Set Up push button a second time will illuminate the Wire Type LED and the lower display will show wire types available for selected processes (see Table

•Pressing the Process Set Up push button a third time will keep Wire Type LED lit and the upper display will show wire alloy type (see Table

•Pressing the Process Set Up push button a fourth time will keep Wire Type LED lit and the upper display will show wire size. The upper display push button will be flashing indicating that turning the Adjust knob will select wire sizes available for that particular process and wire type.

•Pressing the Process Set Up push button a fifth time will illuminate the Gas Type LED and the lower display will show GAS and the upper display will show gas selection (see Table

•If any of the Process, wire type, alloy type, wire size, or gas type was changed, then pressing the Process Set Up push button a sixth time will show PROG in the upper display and LOAD in the lower display. The new program would be loaded for that particular program in slot 1 thru 8. If no changes were made to any setup items, no program will be loaded, and unit will return to standby mode.

•If a custom program is loaded using an optional PDA with File Management/Wa- veWriter software, the Program Display will have a “C” in front of the program number. This indicates that the program is not a factory default program and has been modified. By selecting or changing any process variable and performing a program load will restore the program back to the factory default program.

•Pressing and holding the Process Set Up push button in on power up allows viewing the software revisions of each circuit board in the system. The top display shows the board (PCM, UIM, WFCM, and AIM (auto- mated units only) and the lower display shows the last 3 digits of the circuit board part number plus a letter designator. Press the flashing Feeder Set Up push button to exit the screen displays and continue the power up process.

Table

Wire Description | Wire Abbreviation | Alloy Type | Gas Type | Gas Abbreviation |

|

|

|

|

|

Steel | STL | E70, E100, E120 | 100% CO2, | CO2 |

|

|

| 90% Argon/10% CO2, | C10 |

|

|

| 85% Argon/15% CO2, | C15 |

|

|

| 75% Argon/25% CO2, | C25 |

|

|

| 95% Argon/5% CO2, | C5 |

|

|

| 95% Argon /5% O2, | OX5 |

|

|

| 98% Argon/2% O2 | OX2 |

Stainless Steel | SS | 308, 309, 312, 316 | 98% Argon, 2% O2 | OX2 |

|

|

| (81Ar/18HE/1CO2 | Tri Gas |

|

|

|

| |

|

|

| Tri Gas | |

|

|

| MIG/RMD) |

|

|

|

|

|

|

Cored Tubular Wire | MCOR | 71, 76, 86R, 409 | 90% Argon/10% CO2 | C10 |

|

|

| 98% Argon/2% O2 | OX2 |

Aluminum | ALUM | 4XXX, 5XXX | 100% Argon | ARGN |

|

|

|

|

|

* Not all wire types may be available with your unit. |

|

| ||

|

|

|

|

|