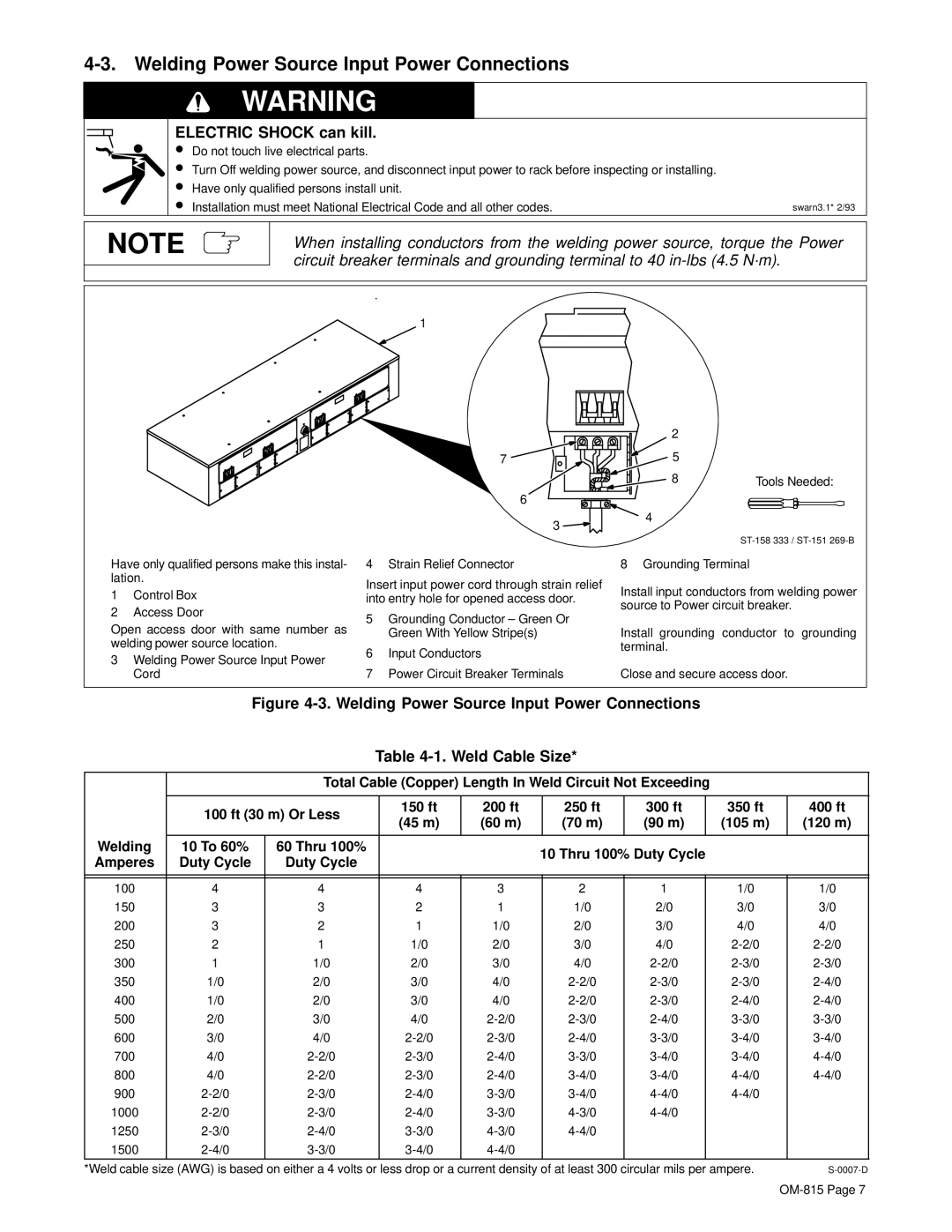

4-3. Welding Power Source Input Power Connections

WARNING |

ELECTRIC SHOCK can kill. |

| |

• | Do not touch live electrical parts. |

|

• | Turn Off welding power source, and disconnect input power to rack before inspecting or installing. |

|

• | Have only qualified persons install unit. |

|

• | Installation must meet National Electrical Code and all other codes. | swarn3.1* 2/93 |

NOTE

When installing conductors from the welding power source, torque the Power circuit breaker terminals and grounding terminal to 40

Have only qualified persons make this instal- lation.

1Control Box

2Access Door

Open access door with same number as welding power source location.

3Welding Power Source Input Power Cord

1

7

6

3 ![]()

4 Strain Relief Connector

Insert input power cord through strain relief into entry hole for opened access door.

5Grounding Conductor – Green Or Green With Yellow Stripe(s)

6Input Conductors

7Power Circuit Breaker Terminals

2 |

|

5 |

|

8 | Tools Needed: |

4

8 Grounding Terminal

Install input conductors from welding power source to Power circuit breaker.

Install grounding conductor to grounding terminal.

Close and secure access door.

Figure 4-3. Welding Power Source Input Power Connections

Table 4-1. Weld Cable Size*

|

| Total Cable (Copper) Length In Weld Circuit Not Exceeding |

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

| 100 ft (30 m) Or Less | 150 ft | 200 ft |

| 250 ft | 300 ft |

| 350 ft |

| 400 ft | |

| (45 m) | (60 m) |

| (70 m) | (90 m) |

| (105 m) |

| (120 m) | ||

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

Welding | 10 To 60% | 60 Thru 100% |

|

| 10 Thru 100% Duty Cycle |

|

|

| |||

Amperes | Duty Cycle | Duty Cycle |

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

| ||

100 | 4 | 4 | 4 | 3 |

| 2 | 1 |

| 1/0 |

| 1/0 |

150 | 3 | 3 | 2 | 1 |

| 1/0 | 2/0 |

| 3/0 |

| 3/0 |

200 | 3 | 2 | 1 | 1/0 |

| 2/0 | 3/0 |

| 4/0 |

| 4/0 |

250 | 2 | 1 | 1/0 | 2/0 |

| 3/0 | 4/0 |

|

| ||

300 | 1 | 1/0 | 2/0 | 3/0 |

| 4/0 |

|

| |||

350 | 1/0 | 2/0 | 3/0 | 4/0 |

|

|

| ||||

400 | 1/0 | 2/0 | 3/0 | 4/0 |

|

|

| ||||

500 | 2/0 | 3/0 | 4/0 |

|

|

| |||||

600 | 3/0 | 4/0 |

|

|

| ||||||

700 | 4/0 |

|

|

| |||||||

800 | 4/0 |

|

|

| |||||||

900 |

|

|

|

| |||||||

1000 |

|

|

|

|

| ||||||

1250 |

|

|

|

|

|

| |||||

1500 |

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

| ||

*Weld cable size (AWG) is based on either a 4 volts or less drop or a current density of at least 300 circular mils per ampere. |

| ||||||||||

|

|

|

|

|

|

|

|

|

| ||