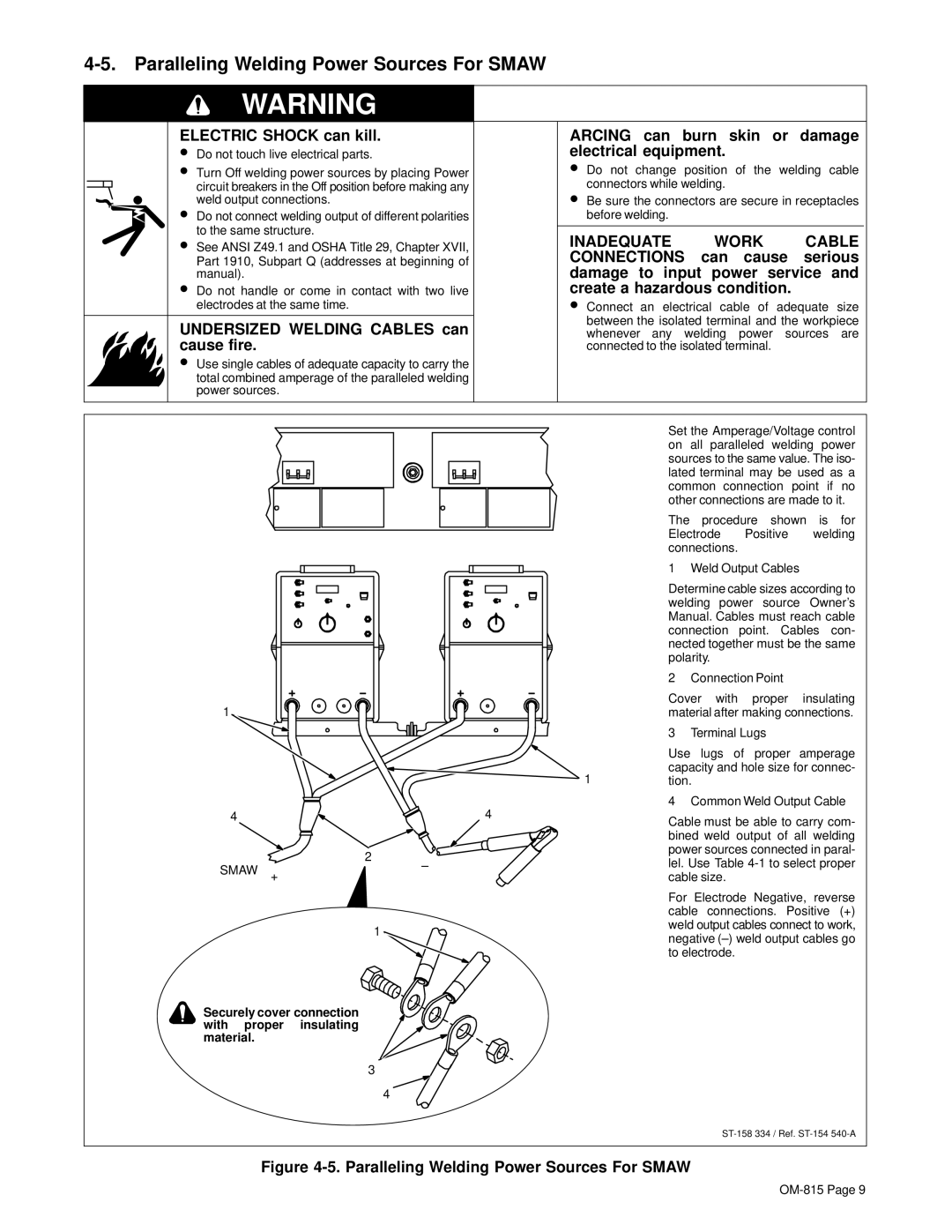

4-5. Paralleling Welding Power Sources For SMAW

WARNING |

ELECTRIC SHOCK can kill. | ARCING can burn skin or damage | ||||

• | Do not touch live electrical parts. | electrical equipment. |

| ||

• | Turn Off welding power sources by placing Power | • | Do not change position of the welding cable | ||

| circuit breakers in the Off position before making any | • | connectors while welding. |

| |

• | weld output connections. | Be sure the connectors are secure in receptacles | |||

Do not connect welding output of different polarities |

| before welding. |

|

| |

• | to the same structure. | INADEQUATE | WORK | CABLE | |

See ANSI Z49.1 and OSHA Title 29, Chapter XVII, | |||||

| Part 1910, Subpart Q (addresses at beginning of | CONNECTIONS | can cause | serious | |

• | manual). | damage to input power service and | |||

Do not handle or come in contact with two live | create a hazardous condition. |

| |||

| electrodes at the same time. | • | Connect an electrical cable of adequate size | ||

UNDERSIZED WELDING CABLES can |

| between the isolated terminal and the workpiece | |||

| whenever any welding power sources are | ||||

cause fire. |

| connected to the isolated terminal. |

| ||

• | Use single cables of adequate capacity to carry the |

|

|

|

|

total combined amperage of the paralleled welding power sources.

|

| The procedure shown is for | ||||

|

| Electrode | Positive | welding | ||

|

| connections. |

|

| ||

|

| 1 | Weld Output Cables |

| ||

|

| Determine cable sizes according to | ||||

|

| welding | power source | Owner’s | ||

|

| Manual. Cables must reach cable | ||||

|

| connection | point. Cables con- | |||

|

| nected together must be the same | ||||

|

| polarity. |

|

|

| |

|

| 2 | Connection Point |

| ||

1 |

| Cover | with | proper | insulating | |

| material after making connections. | |||||

|

| 3 | Terminal Lugs |

| ||

|

| Use lugs of proper amperage | ||||

| 1 | capacity and hole size for connec- | ||||

| tion. |

|

|

| ||

| 4 | 4 Common Weld Output Cable | ||||

4 | Cable must be able to carry com- | |||||

|

| |||||

|

| bined weld output of all welding | ||||

| 2 | power sources connected in paral- | ||||

| lel. Use Table | |||||

SMAW | – | |||||

+ | cable size. |

|

| |||

|

|

| ||||

1

Securely cover connection with proper insulating material.

3

For Electrode Negative, reverse cable connections. Positive (+)

weld output cables connect to work, negative

4