Installing the 28-10-0325 Mounting Bracket

6.With the locking pin secured into the mount- ing block clamp, line up the holes in the

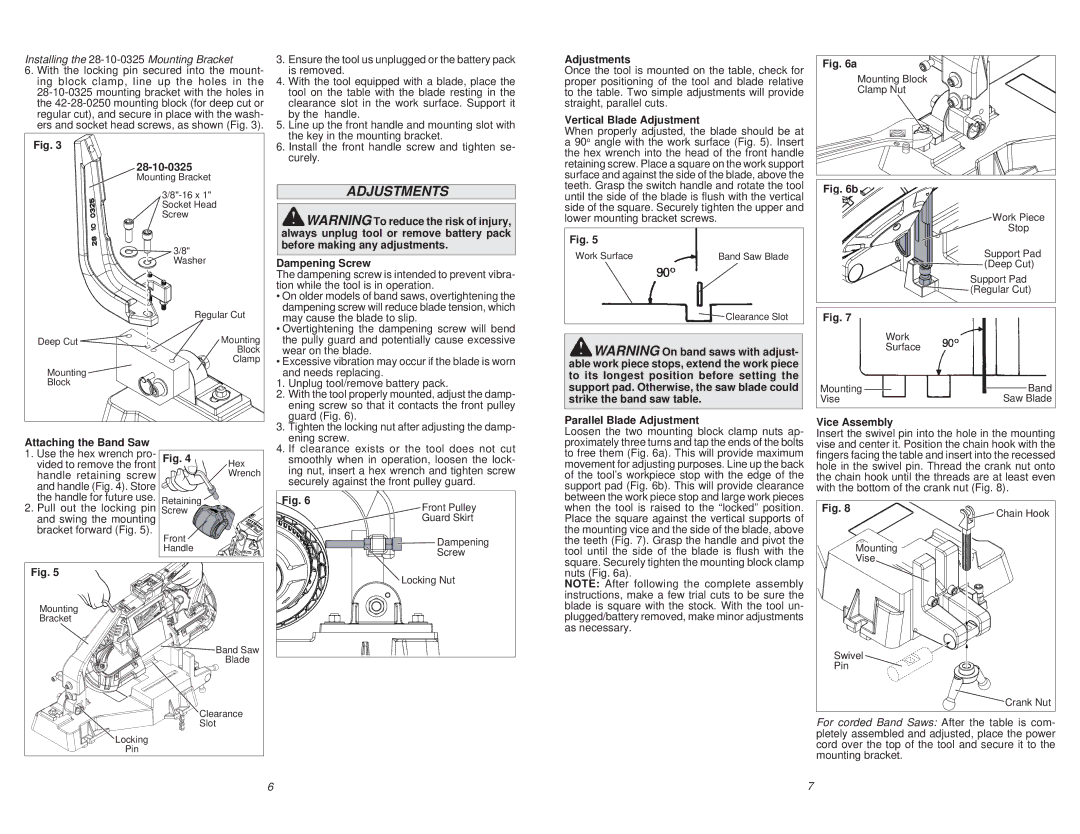

Fig. 3 |

|

|

|

| Mounting Bracket |

| |

| Socket Head |

| Screw |

| 3/8" |

| Washer |

| Regular Cut |

Deep Cut | Mounting |

| Block |

| Clamp |

Mounting |

|

Block |

|

Attaching the Band Saw |

|

|

1. Use the hex wrench pro- | Fig. 4 | Hex |

vided to remove the front |

| |

handle retaining screw |

| Wrench |

and handle (Fig. 4). Store |

|

|

the handle for future use. | Retaining |

|

2. Pull out the locking pin | Screw |

|

and swing the mounting |

|

|

bracket forward (Fig. 5). Front |

| |

| Handle |

|

Fig. 5 |

Mounting |

Bracket |

Band Saw |

Blade |

Clearance |

Slot |

Locking |

Pin |

3.Ensure the tool us unplugged or the battery pack is removed.

4.With the tool equipped with a blade, place the tool on the table with the blade resting in the clearance slot in the work surface. Support it by the handle.

5.Line up the front handle and mounting slot with the key in the mounting bracket.

6.Install the front handle screw and tighten se- curely.

ADJUSTMENTS

![]() WARNING To reduce the risk of injury, always unplug tool or remove battery pack before making any adjustments.

WARNING To reduce the risk of injury, always unplug tool or remove battery pack before making any adjustments.

Dampening Screw

The dampening screw is intended to prevent vibra- tion while the tool is in operation.

•On older models of band saws, overtightening the dampening screw will reduce blade tension, which may cause the blade to slip.

•Overtightening the dampening screw will bend the pully guard and potentially cause excessive wear on the blade.

•Excessive vibration may occur if the blade is worn and needs replacing.

1.Unplug tool/remove battery pack.

2.With the tool properly mounted, adjust the damp- ening screw so that it contacts the front pulley guard (Fig. 6).

3.Tighten the locking nut after adjusting the damp- ening screw.

4.If clearance exists or the tool does not cut smoothly when in operation, loosen the lock- ing nut, insert a hex wrench and tighten screw securely against the front pulley guard.

Fig. 6

Front Pulley

Guard Skirt

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() Dampening

Dampening ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() Screw

Screw

Locking Nut |

Adjustments

Once the tool is mounted on the table, check for proper positioning of the tool and blade relative to the table. Two simple adjustments will provide straight, parallel cuts.

Vertical Blade Adjustment

When properly adjusted, the blade should be at a 90o angle with the work surface (Fig. 5). Insert the hex wrench into the head of the front handle retaining screw. Place a square on the work support surface and against the side of the blade, above the teeth. Grasp the switch handle and rotate the tool until the side of the blade is flush with the vertical side of the square. Securely tighten the upper and lower mounting bracket screws.

Fig. 5

Work Surface | Band Saw Blade |

![]() Clearance Slot

Clearance Slot

![]() WARNING On band saws with adjust- able work piece stops, extend the work piece to its longest position before setting the support pad. Otherwise, the saw blade could strike the band saw table.

WARNING On band saws with adjust- able work piece stops, extend the work piece to its longest position before setting the support pad. Otherwise, the saw blade could strike the band saw table.

Parallel Blade Adjustment

Loosen the two mounting block clamp nuts ap- proximately three turns and tap the ends of the bolts to free them (Fig. 6a). This will provide maximum movement for adjusting purposes. Line up the back of the tool’s workpiece stop with the edge of the support pad (Fig. 6b). This will provide clearance between the work piece stop and large work pieces when the tool is raised to the “locked” position. Place the square against the vertical supports of the mounting vice and the side of the blade, above the teeth (Fig. 7). Grasp the handle and pivot the tool until the side of the blade is flush with the square. Securely tighten the mounting block clamp nuts (Fig. 6a).

NOTE: After following the complete assembly instructions, make a few trial cuts to be sure the blade is square with the stock. With the tool un- plugged/battery removed, make minor adjustments as necessary.

Fig. 6a |

Mounting Block |

Clamp Nut |

Fig. 6b![]()

![]()

![]()

![]()

![]()

Work Piece

Stop

Support Pad

![]()

![]()

![]()

![]()

![]()

![]()

![]() (Deep Cut)

(Deep Cut)

Support Pad

![]()

![]()

![]() (Regular Cut)

(Regular Cut)

Fig. 7

Work

Surface

Mounting |

|

|

| Band |

| ||||

Vise | Saw Blade | |||

Vice Assembly

Insert the swivel pin into the hole in the mounting vise and center it. Position the chain hook with the fingers facing the table and insert into the recessed hole in the swivel pin. Thread the crank nut onto the chain hook until the threads are at least even with the bottom of the crank nut (Fig. 8).

Fig. 8 | Chain Hook |

| |

Mounting |

|

Vise |

|

Swivel |

|

Pin |

|

| Crank Nut |

For corded Band Saws: After the table is com- pletely assembled and adjusted, place the power cord over the top of the tool and secure it to the mounting bracket.

6 | 7 |