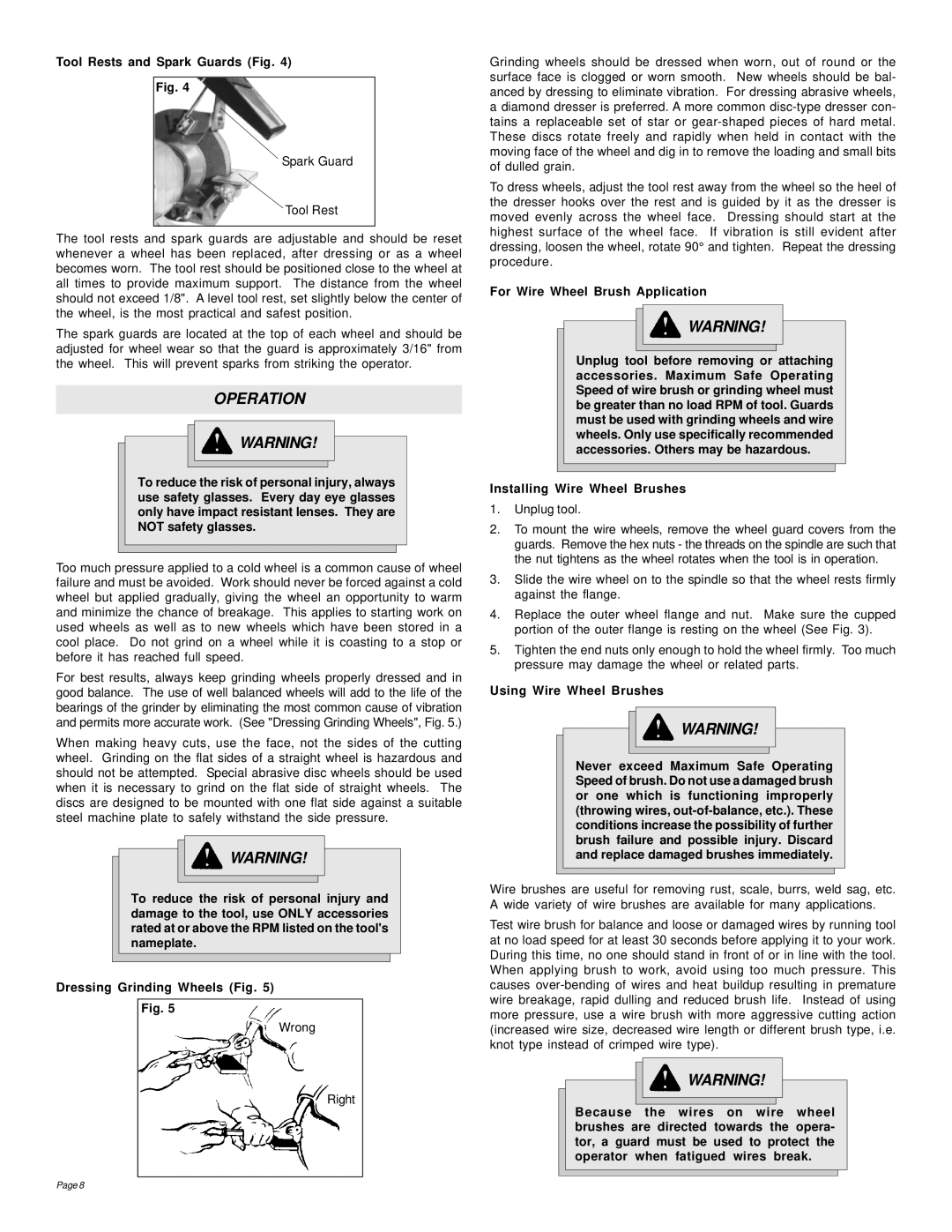

Tool Rests and Spark Guards (Fig. 4)

Fig. 4

Spark Guard

Tool Rest

The tool rests and spark guards are adjustable and should be reset whenever a wheel has been replaced, after dressing or as a wheel becomes worn. The tool rest should be positioned close to the wheel at all times to provide maximum support. The distance from the wheel should not exceed 1/8". A level tool rest, set slightly below the center of the wheel, is the most practical and safest position.

The spark guards are located at the top of each wheel and should be adjusted for wheel wear so that the guard is approximately 3/16" from the wheel. This will prevent sparks from striking the operator.

OPERATION

![]() WARNING!

WARNING!

To reduce the risk of personal injury, always use safety glasses. Every day eye glasses only have impact resistant lenses. They are NOT safety glasses.

Too much pressure applied to a cold wheel is a common cause of wheel failure and must be avoided. Work should never be forced against a cold wheel but applied gradually, giving the wheel an opportunity to warm and minimize the chance of breakage. This applies to starting work on used wheels as well as to new wheels which have been stored in a cool place. Do not grind on a wheel while it is coasting to a stop or before it has reached full speed.

For best results, always keep grinding wheels properly dressed and in good balance. The use of well balanced wheels will add to the life of the bearings of the grinder by eliminating the most common cause of vibration and permits more accurate work. (See "Dressing Grinding Wheels", Fig. 5.)

When making heavy cuts, use the face, not the sides of the cutting wheel. Grinding on the flat sides of a straight wheel is hazardous and should not be attempted. Special abrasive disc wheels should be used when it is necessary to grind on the flat side of straight wheels. The discs are designed to be mounted with one flat side against a suitable steel machine plate to safely withstand the side pressure.

![]() WARNING!

WARNING!

To reduce the risk of personal injury and damage to the tool, use ONLY accessories rated at or above the RPM listed on the tool's nameplate.

Dressing Grinding Wheels (Fig. 5)

Fig. 5

Wrong

Right

Grinding wheels should be dressed when worn, out of round or the surface face is clogged or worn smooth. New wheels should be bal- anced by dressing to eliminate vibration. For dressing abrasive wheels,

adiamond dresser is preferred. A more common

To dress wheels, adjust the tool rest away from the wheel so the heel of the dresser hooks over the rest and is guided by it as the dresser is moved evenly across the wheel face. Dressing should start at the highest surface of the wheel face. If vibration is still evident after dressing, loosen the wheel, rotate 90° and tighten. Repeat the dressing procedure.

For Wire Wheel Brush Application

![]() WARNING!

WARNING!

Unplug tool before removing or attaching accessories. Maximum Safe Operating Speed of wire brush or grinding wheel must be greater than no load RPM of tool. Guards must be used with grinding wheels and wire wheels. Only use specifically recommended accessories. Others may be hazardous.

Installing Wire Wheel Brushes

1.Unplug tool.

2.To mount the wire wheels, remove the wheel guard covers from the guards. Remove the hex nuts - the threads on the spindle are such that the nut tightens as the wheel rotates when the tool is in operation.

3.Slide the wire wheel on to the spindle so that the wheel rests firmly against the flange.

4.Replace the outer wheel flange and nut. Make sure the cupped portion of the outer flange is resting on the wheel (See Fig. 3).

5.Tighten the end nuts only enough to hold the wheel firmly. Too much pressure may damage the wheel or related parts.

Using Wire Wheel Brushes

![]() WARNING!

WARNING!

Never exceed Maximum Safe Operating Speed of brush. Do not use a damaged brush or one which is functioning improperly (throwing wires,

Wire brushes are useful for removing rust, scale, burrs, weld sag, etc. A wide variety of wire brushes are available for many applications.

Test wire brush for balance and loose or damaged wires by running tool at no load speed for at least 30 seconds before applying it to your work. During this time, no one should stand in front of or in line with the tool. When applying brush to work, avoid using too much pressure. This causes

![]() WARNING!

WARNING!

Because the wires on wire wheel brushes are directed towards the opera- tor, a guard must be used to protect the operator when fatigued wires break.

Page 8