5314-21 specifications

The Milwaukee 5314-21 is a versatile and powerful tool designed to meet the demanding needs of professionals in construction and renovation projects. This rotary hammer drill combines innovative technology with robust construction, making it an essential addition to any toolkit.One of the standout features of the Milwaukee 5314-21 is its high-performance motor, which delivers up to 7.0 amps of power. This allows the tool to handle tough drilling tasks with relative ease, making it suitable for a wide range of applications, including concrete, masonry, and even wood. Its impressive drilling capacity of up to 1-1/8 inches in concrete means that users can tackle larger projects without needing to switch tools.

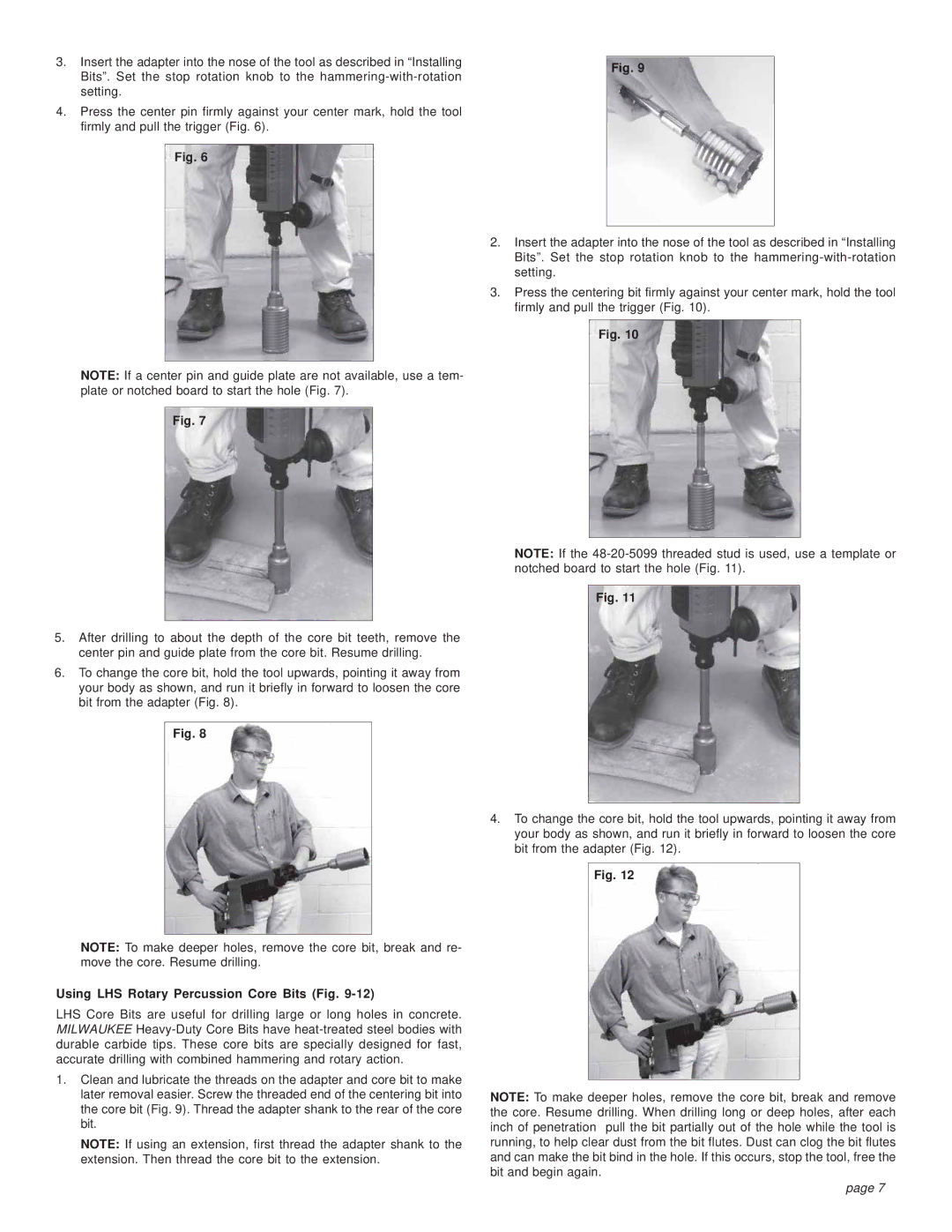

The tool is equipped with an SDS-plus chuck system, which ensures quick and easy bit changes without the need for additional tools. This feature enhances productivity, especially for those who need to switch between different types of bits frequently during a job. Furthermore, the rotary hammer mode can be engaged for efficient drilling in hard materials, while the hammer-only mode is ideal for demolishing tasks.

Another essential characteristic of the Milwaukee 5314-21 is its ergonomic design. The rubber overmold provides a comfortable grip, reducing fatigue during prolonged use. Additionally, the lightweight design of the hammer itself ensures that users can work longer without feeling weighed down.

Safety is a top priority with the Milwaukee 5314-21, which features a two-finger trigger for added control and an electronic reverse for easy bit removal. A depth gauge is included to provide precise drilling depths, ensuring accuracy for various projects.

Overall, the Milwaukee 5314-21 stands out due to its combination of power, versatility, and user-focused design. It excels in both professional and DIY environments, ensuring reliability and efficiency. Whether you are a seasoned contractor or a passionate DIY enthusiast, this rotary hammer drill is engineered to meet a variety of needs while delivering exceptional performance.