GROUNDINGSYMBOLOGY

ASSEMBLY

WARNING Improperly connecting the grounding wire can result in the risk of elec- tric shock. Check with a qualified electrician if you are in doubt as to whether the outlet is properly grounded. Do not modify the plug provided with the tool. Never remove the grounding prong from the plug. Do not use the tool if the cord or plug is damaged. If damaged, have it repaired by a MILWAUKEE service facility before use. If the plug will not fit the outlet, have a proper outlet installed by a qualified electrician.

Grounded Tools: Tools with Three Prong Plugs Tools marked “Grounding Required” have a three wire cord and three prong grounding plug. The plug must be connected to a properly grounded outlet (See Figure A). If the tool should electrically malfunction or break down, grounding provides a low resistance path to carry electricity away from the user, reducing the risk of electric shock.

The grounding prong in the plug is connected through the green wire inside the cord to the grounding system in the tool. The green wire in the cord must be the only wire connected to the tool's grounding system and must never be attached to an electrically “live” terminal. Your tool must

be plugged into an appropriate outlet, prop- erly installed and grounded in accordance

with all codes and ordinances. The |

|

plug and outlet should look like | Fig. A |

those in Figure A. |

Double Insulated Tools: Tools with Two Prong Plugs

Tools marked “Double Insulated” do not require grounding. They have a special double insulation system which satisfies OSHArequirements and com- plies with the applicable standards of Underwriters Laboratories, Inc., the

Canadian StandardAssociation and

the National Electrical Code. Double Insulated tools may be used in ei-

ther of the 120 volt outlets shown in Fig. B Fig. C Figures B and C.

In specific countries, double insulated tools could be used in the output connections suitable for the plug.

Double Insulated

Volts

Alternating Current

W Watts

No Load Revolutions per

Minute (RPM)

Seal of Electrical Security

Read operator's manual

Wear hearing protection

Wear eye protection

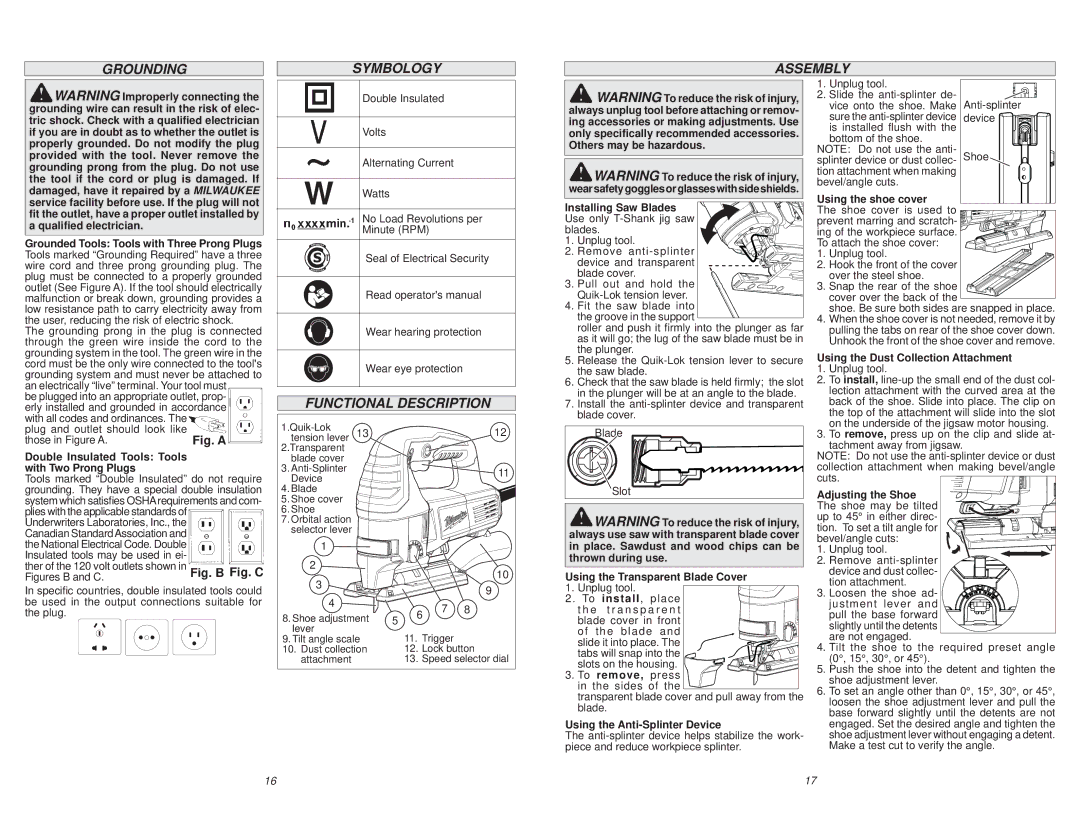

FUNCTIONAL DESCRIPTION

13 |

|

|

| 12 | ||

tension lever |

|

|

| |||

2.Transparent |

|

|

|

|

| |

blade cover |

|

|

|

|

| |

3. |

|

|

|

| 11 | |

Device |

|

|

|

| ||

4. Blade |

|

|

|

|

| |

5. Shoe cover |

|

|

|

|

| |

6. Shoe |

|

|

|

|

| |

7. Orbital action |

|

|

|

|

| |

selector lever |

|

|

|

|

| |

1 |

|

|

|

|

| |

2 |

|

|

|

| 10 | |

3 |

|

|

|

| ||

|

|

|

| 9 | ||

4 |

|

|

|

| ||

|

| 6 | 7 | 8 | ||

8. Shoe adjustment | 5 | |||||

|

| |||||

lever |

|

| 11. Trigger |

| ||

9. Tilt angle scale |

|

| ||||

10. Dust collection |

| 12. Lock button | ||||

attachment |

|

| 13. Speed selector dial | |||

![]() WARNING To reduce the risk of injury, always unplug tool before attaching or remov- ing accessories or making adjustments. Use only specifically recommended accessories. Others may be hazardous.

WARNING To reduce the risk of injury, always unplug tool before attaching or remov- ing accessories or making adjustments. Use only specifically recommended accessories. Others may be hazardous.

![]()

![]() WARNING To reduce the risk of injury, wearsafetygogglesorglasseswithsideshields.

WARNING To reduce the risk of injury, wearsafetygogglesorglasseswithsideshields.

Installing Saw Blades ![]() Use only

Use only ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() blades.

blades.![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() 1. Unplug tool.

1. Unplug tool.![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

2. Remove

4.Fit the saw blade into the groove in the support

roller and push it firmly into the plunger as far as it will go; the lug of the saw blade must be in the plunger.

5.Release the

6.Check that the saw blade is held firmly; the slot in the plunger will be at an angle to the blade.

7.Install the

Blade |

Slot |

![]() WARNING To reduce the risk of injury, always use saw with transparent blade cover in place. Sawdust and wood chips can be thrown during use.

WARNING To reduce the risk of injury, always use saw with transparent blade cover in place. Sawdust and wood chips can be thrown during use.

Using the Transparent Blade Cover

1. Unplug tool.

2. To install, place t h e t r a n s p a r e n t blade cover in front of the blade and slide it into place. The tabs will snap into the

slots on the housing.

3.To remove, press ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() in the sides of the

in the sides of the ![]() transparent blade cover and pull away from the blade.

transparent blade cover and pull away from the blade.

Using the Anti-Splinter Device

The

1. | Unplug tool. |

|

2. | Slide the | |

| vice onto the shoe. Make | |

| sure the | device |

| is installed flush with the |

|

| bottom of the shoe. |

|

NOTE: Do not use the anti- | Shoe | |

splinter device or dust collec- | ||

tion attachment when making |

| |

bevel/angle cuts. |

| |

Using the shoe cover |

| |

The shoe cover is used to |

| |

prevent marring and scratch- | ||

ing of the workpiece surface. | ||

To attach the shoe cover: |

| |

1. | Unplug tool. |

|

2. | Hook the front of the cover | |

3. | over the steel shoe. |

|

Snap the rear of the shoe | ||

| cover over the back of the | |

| shoe. Be sure both sides are snapped in place. | |

4.When the shoe cover is not needed, remove it by pulling the tabs on rear of the shoe cover down. Unhook the front of the shoe cover and remove.

Using the Dust Collection Attachment

1.Unplug tool.

2.To install,

3.To remove, press up on the clip and slide at- tachment away from jigsaw.

NOTE: Do not use the ![]()

Adjusting the Shoe The shoe may be tilted up to 45° in either direc- tion. To set a tilt angle for bevel/angle cuts:

1. Unplug tool.

2. Remove

3. Loosen the shoe ad- justment lever and pull the base forward slightly until the detents are not engaged.

4.Tilt the shoe to the required preset angle (0°, 15°, 30°, or 45°).

5.Push the shoe into the detent and tighten the shoe adjustment lever.

6.To set an angle other than 0°, 15°, 30°, or 45°, loosen the shoe adjustment lever and pull the base forward slightly until the detents are not engaged. Set the desired angle and tighten the shoe adjustment lever without engaging a detent. Make a test cut to verify the angle.

16 | 17 |